The golden rule for lubricant storage is keeping the lubricant “clean, cool and dry”. Let’s discuss 3 ways to improve your lubricant storage.

What are some best practices for lubricant storage at your plant?

- Store Oil Indoors – I’ve seen a few places where oil was stored outside in the elements (a few times covered in ice and snow). If you can, section a room in the plant for lubricant storage. Ensure that room is temperature controlled, access controlled and the necessary fire & spill protections.

- Filter Oil Before Use – Whether you use barrel, cube or bulk tank storage, filtering your oil is a best practice. Most contamination control programs recommend filtering the oil on the way into storage and before putting it into the equipment. If you’re using bulk oil tanks to store oil, when was the last time you cleaned the tank?

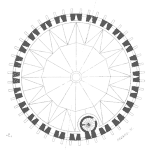

- Label Everything – Labeling is very important to ensure that the right oil is being used for the right application. Labels should include the oil’s viscosity (eg. ISO 46), type (eg. hydraulic), and should be represented as a color & shape. A great example can be found on Machinery Lubrication here. Generally, lubricant labels can be purchased from lubricant suppliers or you can make your own using a label maker.

Reliability Never Sleeps,

Rob

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.

Leave a Reply