Our previous article compared agile/scrum with lean/kaizen and revealed several similar fundamentals that helped make each methodology easier to understand.

Since the objective of lean and agile is waste reduction, we also want to identify and eliminate various forms of waste.

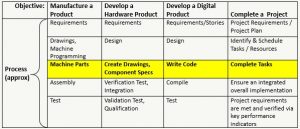

In order to do this, first let’s consider our objective to manufacture hardware product, develop a hardware or digital product and/or execute a project:

Highlighted in yellow are the primary value-added activities within each process.

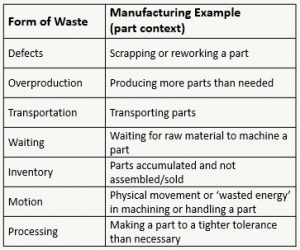

Since it’s easiest to understand a physical process, let’s start by reviewing the forms of waste for machining a part . (While there are general definitions of waste, by explaining waste that happens with ‘parts’, we can explain the forms of waste in a way that’s easiest to understand.)

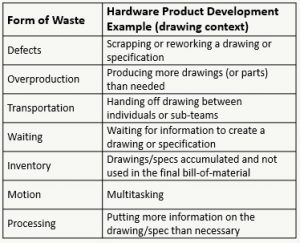

Conversely, it can be seen that a lean process makes just enough, good quality parts at the least amount of cost. Now let’s review the forms of waste specific to creating drawings/specs (hardware product development):

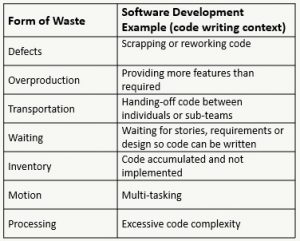

Forms of waste specific to creating code (software product development):

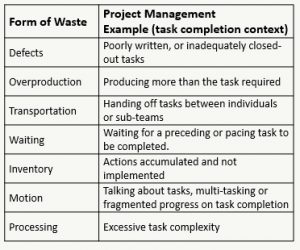

Forms of waste specific to completing tasks (project management):

There’s certainly no shortage of waste in almost any process! The good news is we can put process improvement professionals, systems and processes (like lean product development, agile, lean sigma and project management) into place to minimize it.

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.

Leave a Reply