Chapter 6: Applying Agile Hardware Techniques, Changing the Normalized “Old Ways” Part 2

In the previous chapter the first part of a practical look at how to apply agile methodologies to your hardware development process was explored.

This chapter completes a look at how to apply agile methodologies to your hardware development process.

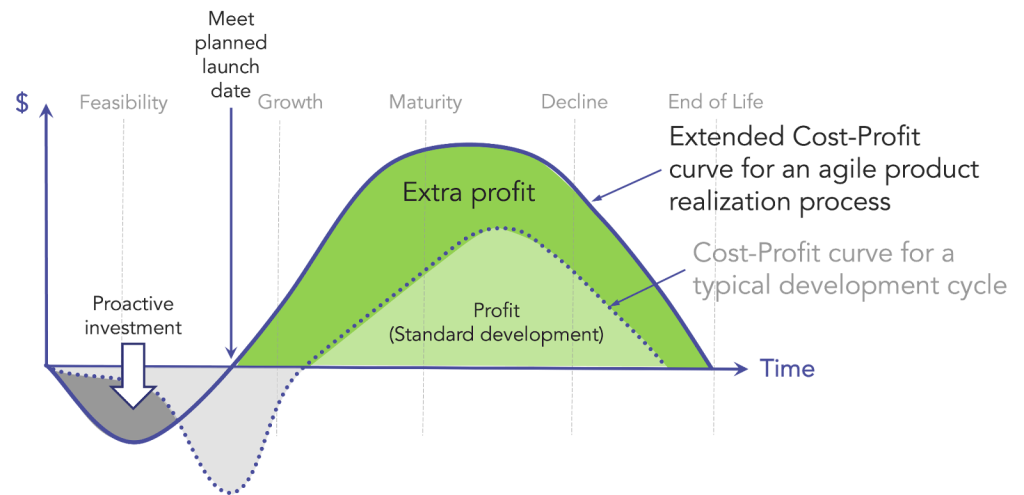

As illustrated in the diagram at the beginning of this blog, companies that follow an agile hardware product realization process plan to invest more resources early in the process and, as a result, are able to realize extra profits over the product’s lifecycle. Compare the two lines showing the investment and profit profile of a standard (old ways) development process (from the diagram shown in the previous blog post) with that of those organizations who invest strategically early in the process.

By aligning resources early and fostering cross-functional collaboration, these organizations gain clearer visibility into requirements, risks and tradeoffs. with the result is a more agile and effective process that delivers measurable business advantages including:

- On time market delivery

- Lower total costs and higher profits

- Products that meet intended requirements.

Some thoughts on current AI-based hardware (electronic) design capabilities

While AI is increasingly useful in many areas of the NPDI process, caution is advised when applying AI tools to electronic circuit design. Unlike software development, where reusable code libraries enable AI to generate effective results, hardware design involves greater complexity and dependency on physical constraints.

Key challenges include:

1. Limited training data – Circuit designs vary widely, and the data available to train AI tools is limited compared to the vast libraries of software code available online.

2. Component complexity – Each part requires detailed evaluation before inclusion in a design.

In software design environments, modular “building blocks” (e.g., reusable functions for Bluetooth connectivity) lend themselves to AI-driven assembly and reuse. With hardware, however, each design must integrate unique, highly specific physical, electrical, and environmental constraints. As a result, full electronic circuit design still requires deep engineering expertise and careful human oversight.

Join us next time to learn how to prepare your organization to have the strong foundational principals needed to fully utilize agile hardware product development.

Sources:

Extracts from the completely revised book Agile Hardware Product Realization (version 4.0) by Michael Keer and David Eden.

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.

Leave a Reply