The duty cycle of a fuel cell engine, particularly in the context of acceleration and deceleration of a vehicle, is a critical aspect that influences the performance, efficiency, and longevity of the fuel cell system. Understanding the effects of these dynamic conditions on fuel cell engines is essential for optimizing their operation and addressing potential challenges.

Effects of Acceleration and Deceleration on Fuel Cell Engines

During acceleration, the demand for power increases rapidly, which can lead to transient responses in the fuel cell system. This sudden increase in power demand can cause temporary inefficiencies in the fuel cell’s operation due to the lag in the response of the fuel cell system components, such as the air supply and hydrogen fuel delivery systems. Conversely, during deceleration, the power demand decreases, which can lead to an excess of hydrogen in the fuel cell stack if the fuel delivery system does not adjust accordingly. This imbalance can affect the fuel cell’s efficiency and performance.

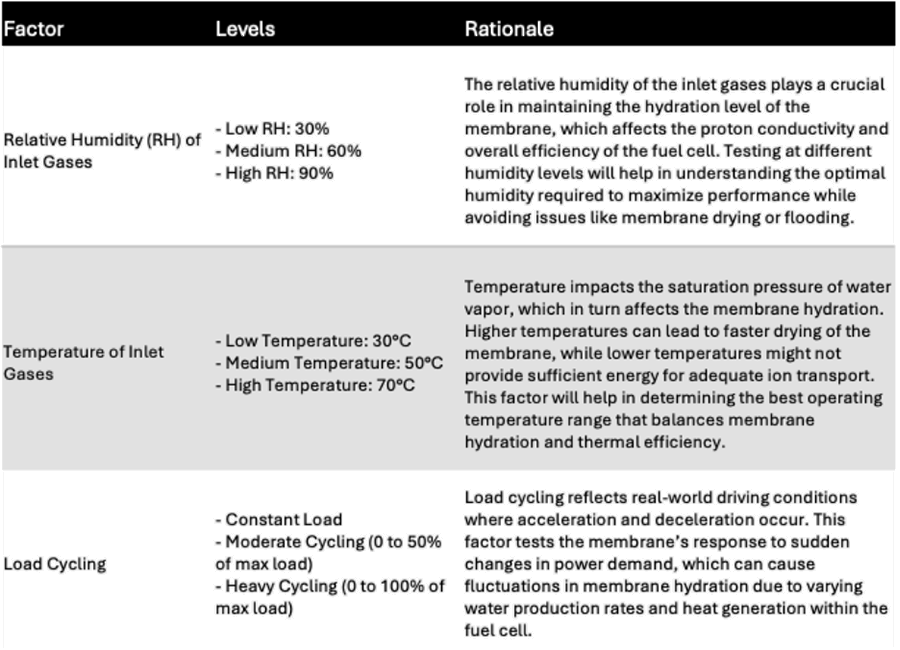

The starts/stops and acceleration/deceleration cycles can cause variations in membrane humidity within the proton-exchange membrane (PEM) fuel cell. Rapid changes in load can lead to fluctuations in the operating temperature and humidity levels within the fuel cell stack. These fluctuations can impact the membrane’s hydration level, which is crucial for ion conductivity and overall fuel cell performance. Over time, this can lead to membrane degradation and reduced fuel cell lifespan.

The dynamic driving patterns, including frequent acceleration and deceleration, impose mechanical stress on the fuel cell components. This stress can accelerate the degradation of the fuel cell stack, particularly affecting the membrane and electrode materials. The repeated cycles of expansion and contraction, as well as the varying pressure conditions, can lead to mechanical failures or reduced material integrity over time.

Solutions and Mitigation Strategies

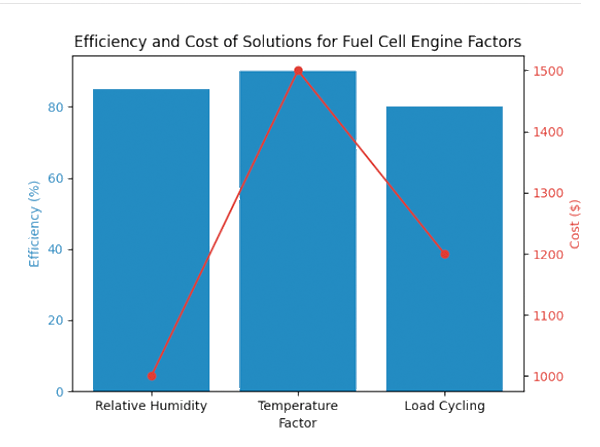

Implementing advanced control systems that can rapidly adjust the fuel delivery and air supply in response to changing power demands can help mitigate the effects of acceleration and deceleration. These systems can optimize the fuel cell’s performance by ensuring a balanced reaction and maintaining optimal operating conditions, even under dynamic loads.

Developing effective humidity management strategies is crucial for maintaining membrane hydration levels during variable driving conditions. This can include the use of humidifiers, condensers, and intelligent membrane hydration control systems that adjust based on the fuel cell’s operating conditions to ensure consistent performance and prevent degradation.

Using materials and designs that can withstand the mechanical stresses associated with dynamic driving patterns can enhance the durability of fuel cell engines. Research into more robust membrane materials, as well as structural designs that can accommodate the mechanical fluctuations without compromising integrity, is essential for improving the longevity of fuel cell systems.

In conclusion, the duty cycle of fuel cell engines, particularly under acceleration and deceleration conditions, presents several challenges to fuel cell performance and durability. Addressing these challenges through advanced control systems, effective humidity management, and the use of durable materials and designs is crucial for optimizing fuel cell engine performance and extending their operational lifespan.

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.

Leave a Reply