Guest Post by Bill Pomfret (first posted on CERM ® RISK INSIGHTS – reposted here with permission)

The start of fall might feel too soon to begin preparing for next winter. But with memories of snowstorms fresh in your mind, now is the perfect time to review your emergency response plans. Preparing emergency response plans of time also means you’ll be ready when snow, tornadoes, hurricanes, wildfires, drought, or other types of severe weather hit.

Emergency preparedness is one of the most important things a company can invest in. When an emergency happens, being prepared can be the difference between the loss of money, time, and—most importantly—the safety of your staff. Thanks to advances in technology, companies can implement platforms and tools that can help them prepare for anything from inclement weather to a dangerous intruder or a pandemic.

Despite improved accuracy in weather predictions, businesses are not always equipped with the necessary infrastructure to prepare a proper emergency response, wasting precious time during an emergency that could have been avoided. Therefore, it’s important for companies to have the right safety and communication technology so they can protect their employees and property in the event of a weather emergency.

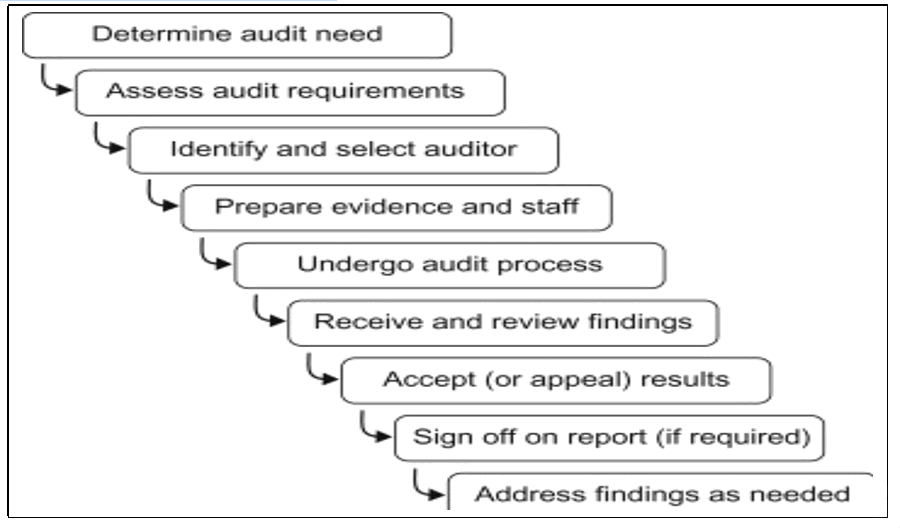

Step 1: Audit your current practices and systems.

The first step to being prepared for a winter storm or any other emergency is to audit your company’s current safety and emergency plans. Over time, safety plans can become dated, and depending on the last time your plan was reviewed, it can even be counterproductive in an emergency. Making sure your plan is fresh and up to date with your facility’s current infrastructure guarantees that when an emergency arises, you are prepared.

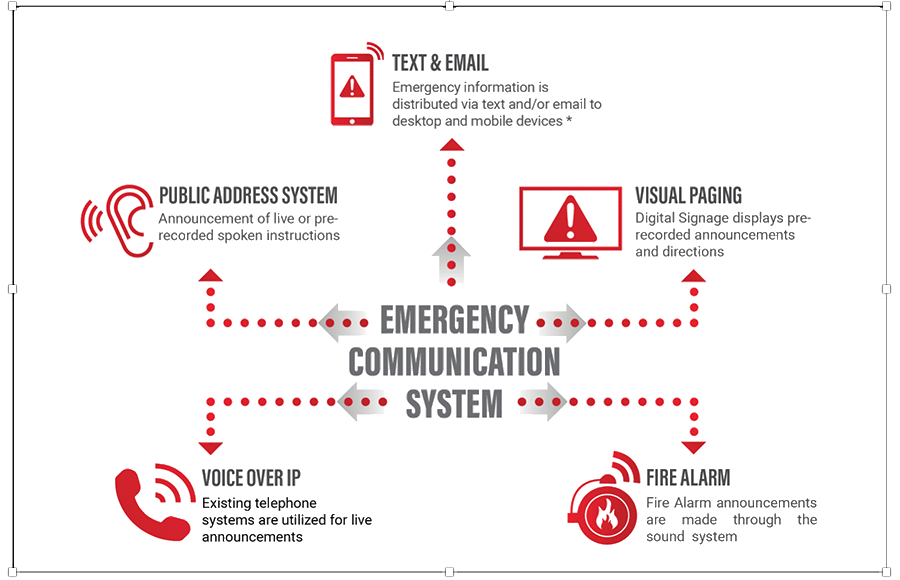

A great way to begin is by identifying all your existing safety and communication technologies. Often, companies already have a wide variety of systems in place, such as door access control, fire panel, cameras, temperature, or moisture monitoring. When it comes to communicating, companies use email, text, phone calls and other tactics to reach employees with timely messages, often distributed from a variety of communication platforms.

Once all these systems are accounted for, you can determine how these technologies can be best utilized together as a single unit rather than as separate systems. It’s important to consider how to get the most out of your current safety and technology framework as you create an improved emergency response plan.

Step 2: Integrate your technology.

Companies that can integrate their existing technologies in a more efficient way have a competitive advantage when triaging emergencies. For instance, companies can integrate all their existing safety systems onto a single platform with an emergency alerting platform.

An automated alerting platform gathers all the information from the previously disparate technology systems, monitors them and sends detailed alerts from one source. Not only does this allow the company to get the most out of its previous investments, but it also simplifies emergency responses.

Rather than having to access each of these technologies separately, they can be tied into the emergency alerting platform. That means when any of the systems are triggered, an alert will automatically be sent out to the properly assigned individuals.

For example, say a facility’s door access control and temperature sensors are both integrated into an emergency alerting platform, the alerting platform will constantly be monitoring those systems. If either are triggered, an alert regarding what has happened will automatically be sent out.

Step 3: Customize your alerts.

With an emergency alerting platform, any company can improve the functionality of their current technologies by enhancing their alerting capabilities. The alerts are entirely customizable, including from which end users they are sent to and the information they contain. This allows for the quick and direct dispersal of information during an emergency.

Whether maintenance, security, police, or a senior employee needs to be contacted, that can be pre-determined depending on the triggered event. For example, if during a winter storm, a pipe bursts in the building and a moisture monitor is set off, a detailed alert can be sent to maintenance personnel immediately, ensuring that the situation is handled as quickly as possible.

This kind of automation can ensure that even when employees aren’t in the building, whether due to a pandemic, or snowstorm or any other situation, a response will still be triggered. This can seriously reduce response times to any emergency and can help companies save time, money, and resources. In a dangerous scenario, enhanced emergency alerting can even save lives.

Step 4: Bolster communication.

Automated emergency alerting isn’t the only way to keep your company informed during an emergency. A mass notification platform is another great tool that can allow companies to keep their employees informed about any situation. For example, if a winter storm hits and causes closures, transportation difficulties or any other problem, then specific employees, groups of employees or the entire employee workforce can be notified immediately. These alerts can be pre-set or customizable, and they can be sent via text message, voice call and/or email.

Being prepared for inclement weather doesn’t have to be complicated. The main things to focus on are taking advantage of the systems and tools that are already available to you as well as ensuring you have a communication platform that can keep everyone informed. Ensuring fast and proper dissemination of information will help keep employees safe.

Emergency preparedness is a year-round job. Concerns like winter weather only elevate the importance of having a plan in place. Not only will this help during the next snowstorm, but it will enhance emergency preparedness and safety plans for any situation.

Step 5: Training Exercises

It’s important to have the process, tools, and templates in place first, and use these as the basis for training your team on how to apply them to different situations. Scenario-based workshop training is a good place to start, helping the group to understand good practice alongside how to apply those principles in different situations.

Then, you’ll want to stress-test the team’s ability to put things into practice under pressure – maybe as a crisis simulation exercise or emergency drill, to validate their readiness to perform independently.

It is essential that every few months you exercise your plan with realistic practical exercises, on different shifts, with different personnel on duty.

Bio:

Dr. Bill Pomfret of Safety Projects International Inc who has a training platform, said, “It’s important to clarify that deskless workers aren’t after any old training. Summoning teams to a white-walled room to digest endless slides no longer cuts it. Mobile learning is quickly becoming the most accessible way to get training out to those in the field or working remotely. For training to be a successful retention and recruitment tool, it needs to be an experience learner will enjoy and be in sync with today’s digital habits.”

Every relationship is a social contract between one or more people. Each person is responsible for the functioning of the team. In our society, the onus is on the leader. It is time that employees learnt to be responsible for their actions or inaction, as well. And this takes a leader to encourage them to work and behave at a higher level. Helping employees understand that they also need to be accountable, visible and communicate what’s going on.

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.

Leave a Reply