Two of the most common acronyms used regarding manufacturing screening processes are ESS and HASS.

ESS stands for “Environmental Stress Screening” and HASS stands for “Highly Accelerated Stress Screening.”

How are they different?

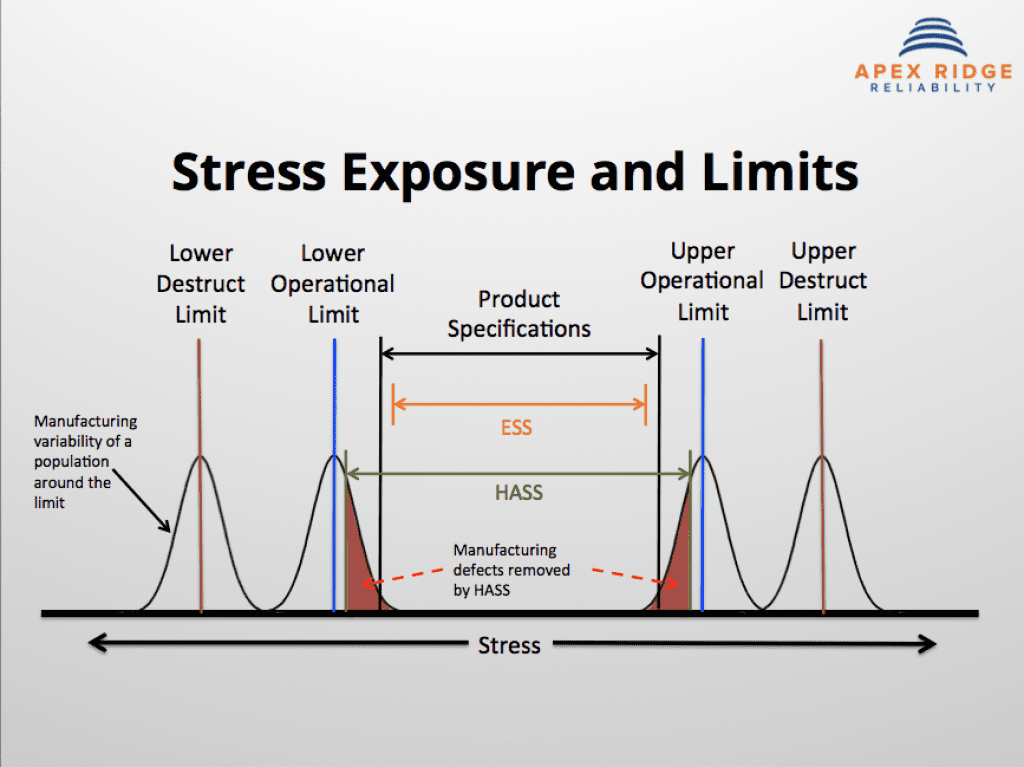

Here is the most fundamental differentiator: ESS uses the known product specification limits to test for defects, whereas HASS applies stresses that are beyond the product specifications but just under the operational limits.

Product “specification limits” used in ESS are the maximum stress values to which the product is intended to be exposed in the field.

Product “operational limits” used in HASS are the stress levels that, when applied, inhibit the product from performing correctly (the beginning of the end!).

Often, when these operational limit stresses are removed, the product returns to normal operation (a soft fail).

The operational limits are not identified in the product development process unless HALT (Highly Accelerated Life Testing) has been executed.

From HALT to HASS

HASS utilizes the information learned during HALT to target the identified failure modes with very high stress so that faults can be found quickly.

Understanding the product limits from HALT also ensures that the product is not damaged nor has had too much life removed.

This allows for a full screening of all products in production.

This graphic demonstrates the relationships:

HASS stress levels are derived from HALT results based on multiple input factors.

The general ranges of typical HASS stresses are as follows:

- Vibration is in the range of 35% to 65% of the vibration operational limit.

- Temperature is in the range of 65% to 95% of temperature limits.

- Stress durations are usually around 5 minutes per step.

An important final step in the HASS development process is “proof of screen”.

Proof of screen ensures that that product life has not been consumed beyond established limits and that HALT-discovered quality defects are exposed.

Terms

- Specification Stress – Stress level limits expected during field use.

- Operational Limit – Stress level at which product does not perform correctly. The product typically recovers when the stress is removed.

- Destruct Limit – Stress level at which product is disabled. The product does not recover when the stress is removed.

- HASS (Highly Accelerated Stress Screening) – Quality test based on HALT results that are done on 100% of manufactured product. Stresses go beyond the product specification but are less than the Operational Limit stress.

- HASA (Highly Accelerated Stress Audit) – Quality test based on HALT results done on a selected percentage of manufactured product. Stresses go beyond product specification but are less than the Operational Limit stress.

- ESS (Environmental Stress Screening) – Quality test done on 100% of manufactured product. Stresses are less than the specification stress.

Related:

When to Conduct HALT (article)

Life Testing Starting Point (article)

4 Steps to Accomplish HALT (article)

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.

How do you derived a good profile with precipitation and Detection together. What type of vibration would be added (saw tooth or just a normal square type of vibration). How does these two vibrations respond to failures. Can you share more thru my email. Thx