Guest post by David Mosaddar

Data Mining Techniques to Increase Productivity in Maintenance Management Systems

Let a Plant Wellness Way EAM System-of-Reliability End Your Business Risks Forever

Today, the use of a Computerised Maintenance Management System (CMMS) and user-friendly software packages have made the job of the maintenance crew relatively easier. The entire maintenance system seems to be at your fingertips, with Key Performance Indicators (KPIs) in flashy dashboards on a computer screen. But is that the absolute best use of your maintenance information?

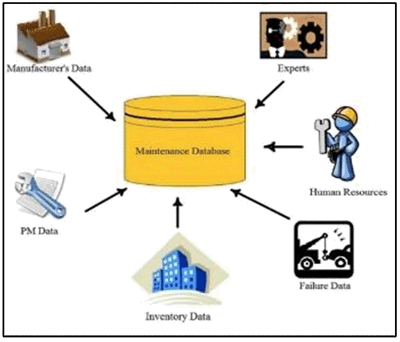

All maintenance systems produce data which are used to observe and monitor the condition of the assets in the company. These data are usually stored in huge maintenance databases. Figure 1 overviews the sources of data available to be interrogated and analysed for business information and added value.

It is a known fact that data gathered in maintenance systems, sometime gained with a lot of difficulties, often lays in the databases untouched for years. A recent survey suggested that many databases in the successful companies are not normally touched but are used as a sort of archive for the rainy day when the need to investigate them arises! This data hibernation could be for a variety of reasons, either there was no need felt to use it, a lack of knowledge in database mining, a lack of knowledgeable data analysts, etc. Whatever the reason, it is becoming a common belief those untouched databases are ‘dormant volcanos’ of historic knowledge that hold insights into the causes of past performance, which can be released to produce a tremendous competitive edge. This realisation of the great value in stored data has collectively become known as ‘big data’ analysis—also known as data mining.

There are now many ways to extract useful information from maintenance databases, and Knowledge Discovery in Databases (KDB) and data mining are nowadays trendy terms in this area. However, what needs to be recognised is the fact data mining cannot perform miracles. It is a multidisciplinary science with many tools and techniques that needs close cooperation from both the data-miner and the business being mined.

There are data mining methods that interrogate and use the information in your organisation’s database to tell you not only about the conditions of your assets, but also to provide you with new, insightful information in terms of why a particular item in your asset register has ended up in the condition it now is!

Finding the condition of an asset based on different variables held within the variety of databases of their business system is an opportunity not taken advantage of by most companies. Using maintenance KPIs along with other business KPIs can be helpful here. For instance, mean time between failures, asset age, environmental conditions, depreciation, conditions of working under overload, operational cost, etc. reflect an asset’s current condition. However, the problem that many companies face is how do you use this mass of information spread across their business and take such various data to gauge the condition of an asset on their site.

Data mining techniques now provide great opportunities to facilitate such daunting tasks. For example, using data mining techniques would make it possible to analyse the asset condition by including as many operating health and reliability factors as needed. The power behind data mining techniques is it enables the data miner and experts in the field to work together to use the data from historic databases in ways which were before considered to be not of much use.

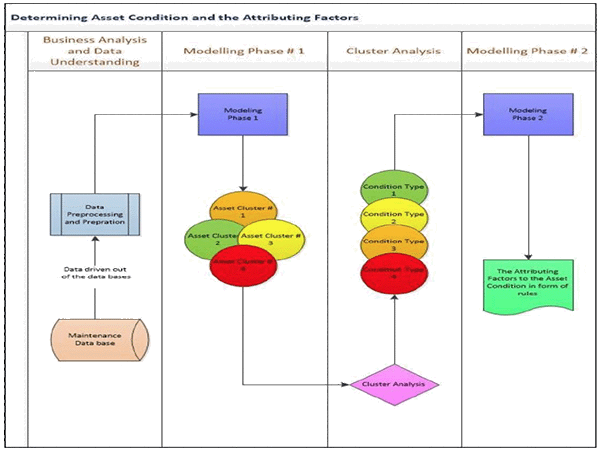

Figure 2 depicts the CMMS data mining and data analysis process.

After extracting the data from the database, they are cleaned and pre-processed. In the first phase of modelling the asset items are divided into different groups called clusters. This is done using different clustering algorithms. The clusters are then analysed for their properties. Based on the properties of the clusters, the assets in them are classified.

n the next stage, the factors that caused the asset to be placed in each cluster are investigated. Using a whole new set of data mining algorithms all the factors that can cause an asset item to have a certain condition are derived from the data in forms of ‘if-then’ rules. One example of such a rule might be: if a certain Preventive Maintenance (PM) activity is performed more than 10 times, then the asset item ends up in a particular condition (these conditions have been identified and defined).

What can you do with the knowledge already in your maintenance databases, once identified by doing ‘big data’ mining analysis, to put your assets into clustered groups and the inherent conditions of each group identified?

Take maintenance training for instance. Many companies train their maintenance staff or ask them to take on-the-job-training courses, to improve the outcome of the work done on the workshop floor. By identifying the unproductive PM activities using the above-discussed historic data mining and data analyse method, you narrow down the maintenance training into the needed areas, hence saving time and capital!

Another example is identifying when the lack of PM activities, or not properly performing those PM’s you have, degrades an asset’s operational condition. The maintenance activities that led an asset being in a particular physical health condition or failure state can be identified. Furthermore, by identifying the unproductive an ineffective maintenance activity, asset managers could make more informed decisions of what to do to make the needed amendments in the maintenance strategy under their control.

CMMS data mining analysis greatly helps in understanding the underlying and hidden conditions of an asset, and the historic causes of its behavioural properties, which might not be noticed in normal day to day activities. This is all done by using the data sitting dormant in your existing business and maintenance databases.

David Mosaddar

Maintenance Data Analyst

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.

Leave a Reply