The article was written to cause people to question traditional approaches to FRACAS. In time senior managers in companies will come to realise that FRACAS has little chance of successfully improving their company. They then can instead look for what does work to move their operations to world class production performance.

Keywords: FRACAS, root cause analysis, RCA, failure modes, problem solving

Many reliability and maintenance consultants will tell you to use a failure reporting, analysis and corrective action system (FRACAS). But if you use a FRACAS in the traditional way, to identify problems, it takes years to make substantial reliability growth gains. Yet the same reliability gains can be gotten in months if FRACAS is focused on what causes your greatest successes. Those reliability and maintenance consultants who recommend you use a FRACAS presume that implementing a conventional FRACAS is useful, sound and successful advice to give you. We do not make the assumption a FRACAS is worthwhile! We recommend you never, never, never use a FRACAS, unless you do it a very particular way.

It is a misuse of a FRACAS if its use focuses you on the problems in your business. Once the human mind is focused on finding problems then problems is all that you find. The intention of doing FRACAS is to solve your problems. Problems are overcome by finding the right solution—you want answers that work, but you’ll only see endless problems listed in your FRACAS. The second danger of having a FRACAS is you will seek individual solutions to individual problems when in fact nearly all of your problems are due to failures of your business system. There is another, better way to use a FRACAS—use it to find when things go right and then replicate the most successful solution all the time as standard operating practice.

If you want to stop your problems do not focus on them; focus only on doing their solutions! To use a failure reporting, analysis and corrective action methodology that gets you looking for problems means you only see problems everywhere you look. Heart ache after heart ache, involving years and years of work, will appear on your FRACAS list. It depresses you.

It’s easy to apply wrong logic to justify establishing and using a FRACAS. The thinking goes something like this, “In order to solve our maintenance and reliability problems we must find them and list them so we can fix them in priority order.” It even sounds reasonable: find each important problem and then solve it. What is seemingly logical to you to do does not mean it is actually the best thing to do!

Once you have a FRACAS you’ll go chasing all your operation’s problems. You will also need to apply a root cause analysis (RCA) methodology; you’ll be buying software like Taproot, or Apollo, or one of the other RCA software; you’ll be training RCA teams of people from across the company; there will be RCA Team Facilitators to train; you’ll be writing reports (lots of reports) to your management requesting funds and new resources. In the end your company will give up and stop doing RCA’s because the problems never end. A strategy of finding problems and fixing them will guarantee you will always be working on problems—yet you actually want solutions.

In a Plant Wellness Way EAM System-of-Reliability you approach business process problem solving in a different way. One that is based on statistical analysis.

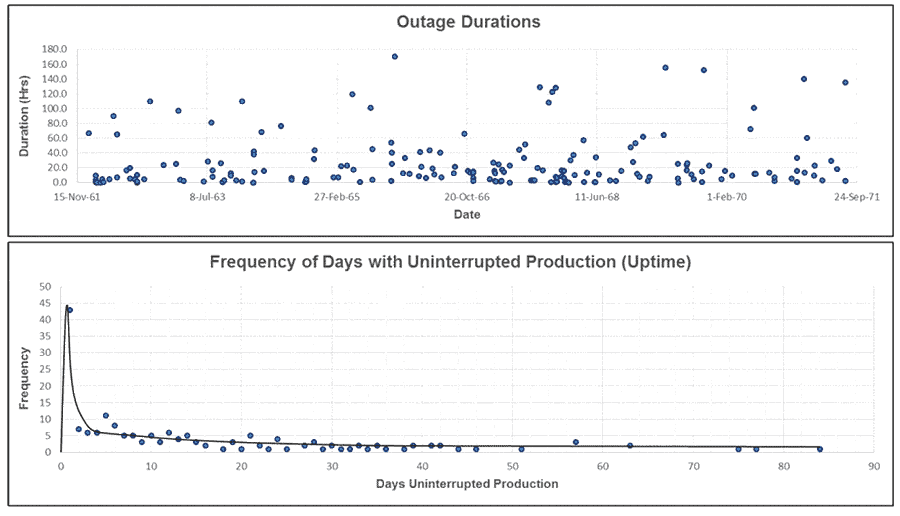

Figure 1 shows a run chart of outage duration events on top, and the frequency of the remaining Uptime at the bottom. If you used a FRACAS your spread sheet would list all the outage points shown on the run chart. Every time there was a problem you would have recorded it in your FRACAS. They can quickly tally in the hundreds of failure events you are trying to fix. The run chart is just of one plant and one type of failure category: downtime. Imagine if your FRACAS listed all the problems in your company. Good luck trying to quickly work your way through a never-ending list of hundreds of problems. Most companies just give up because the task of endlessly fixing hundreds of problems becomes a mountain impossible to climb. Instead we’d suggest you take a different tack to using a FRACAS.

You want to prevent maintenance and reliability troubles, not find them and fix them once you have them. There is a far better answer to getting plant and equipment reliability growth than using traditional FRACAS. It is far more successful, and it will get you the world class performance you want sooner, than the standard use of FRACAS can ever achieve. But first you need to watch what is actually happening in your business. You need to ‘see’ the results of your processes in action.

We use statistical distribution curves to ‘see the process’ behaviour. Once you have a ‘picture’ of how a business process actually performs you trump the common FRACAS approach because you can ‘see’ the results of both successful behaviour and of the problems you have in your operation. Once you identify the successes you research their causes and make them your standard operating practice.

What successes can you see in the Uptime distribution curve? The curve shows the frequency of downtime outages suffered, from most often to least often as you move rightward along the curve. On the right are all the best successes—the longest Uptime periods this company had. With the performance distribution curve the big Uptime successes are obvious.

What now needs to be done is to find out why those successes happened. We want to know what we did, or did not do, that brought us our greatest successes. We do not bother to find out why the failures happened, because if we do more of what makes our process successful there will naturally be fewer and fewer failures. This is why we do not want you to wrongly use a FRACAS and focus on your problems—you will miss the causes of your greatest successes!

The best way to use a FRACAS is to compare the records in the FRACAS made during the bad periods, with the lack of records made during the good periods. What did not happen in the good times that did happen in the bad times? Instead of looking at one problem in isolation and focusing on it, you will list the causes that prevented the process from being as successful as it could have been.

Some failures will repeat over and over. They are surely business process design failures. Occasionally a failure will appear that is in isolation and is unlike any other—these are one-off events that randomly impacted your operation. By using a FRACAS like this you will be forced to view your business processes holistically and consequently identify the many systematic problems that are causing nearly all the individual failures noted in your FRACAS. Once you work on your business at the system level you get rapid and massive improvements. But if you work on your business at the problem symptoms level you will drown in details and never make the necessary system changes to stop the root causes of your problems.

By comparing the duration of your successes alongside the number of worst events that happened during equally long time periods you can no longer consider each problem in isolation. You’ll take your focus away from finding the causes of individual problems and instead look at how to build processes that do not allow any failures to happen. You will begin to see what you need to do to your processes to make them robust and anti-fragile. You are forced to take a business-wide, life-cycle long view and look at installing systematic solutions into your company. System improvements are the ones that bring the greatest and most profitable successes.

The financial justification to work at system level improvements will be easy to quantify—the costs of your problems will now become profits. You will turn your company processes around so that your greatest successes become the standard practice. All the moneys lost on the left-hand side of your distribution curve from each problem you solve will become new operating profits forevermore.

All the very best to you,

Mike Sondalini

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.

Leave a Reply