Guest Post by Malcolm Peart (first posted on CERM ® RISK INSIGHTS – reposted here with permission)

Orders and being ordered can mean many things to many people. In biology order concerns the taxonomic rank for classifying organisms. More generally speaking it concerns the arrangement of people or things in relation to each other in some form of pattern, sequence, or method. Alternatively, it can mean an authoritative command or instructions that are, typically, conveyed in a particular sequence. When ordering a meal, for example, it’s normally done in the order in which the food will be served, but that’s always best clarified in some countries!

However, and despite orders regulating many of the things we do and being an intimate part of our lives, the concept of giving or taking ‘orders’ is taken as reprehensible and repugnant behaviour by some. Ordering for them, outside of restaurants or other purveyors of supplies, smacks of being in the army or being subjugated. Regimentation and discipline are often frowned upon by some of our more sensitive colleagues.

Despite the sensitivities of some people regarding the giving and receipt of orders, the issuance of instructions as well as the imposition of rules and regulations are an essential part of our day-to-day lives as well as work. Society also depends on structured communication which, although subliminal, is an integral part of culture. In the absence of such structure, or order, a society can quickly become anarchic.

When it comes to projects even established organisations with proven track records for successful projects can, and do, experience failure at worst or less than anticipated outcomes at best despite engaging experienced, and qualified personnel. One of several reasons for such project outcomes is the absence of ‘good communication’ which leads to troubled projects and less than complete success. But what is ‘good communication’ and why should it be ordered?

Good Communication

Communication, or rather information logistics, is about the transmission and receipt of the right information, to the right people, in the right medium and at the right time. “Good communication” can be a matter of opinion but, in reality, it’s about getting a message through clearly, concisely and timeously so that it’s fully understood. And when it comes to projects the communication of a project execution plan is a fundamental aspect of any project, or rather should be.

The Project Execution Plan, as opposed to a plan describing the various knowledge areas of project management and how they will be implemented, is an important, if not crucial part of a project but is sometimes significant by its absence. Planning, as we know, should precede execution, or the action taken could well become a nightmare. Hence it is imperative that the plan is communicated from the outset to the project team and predetermined stakeholders prior to its implementation…but how?

Plans are best conveyed in writing and must address the what, why, when, how, where and the who in a sensible and logical order. It should describe the circumstances under which a project is being undertaken, the parties involved, the chosen course of action and the risks that have been considered. The undertaking of the project can also be considered in terms of a project’s novelty, technology, complexity, and pace. Of course, no plan is perfect and as such plans must be maintained and upgraded to accommodate change; change too must be communicated and change can quickly make the best laid plans redundant and ineffective.

Military Orders

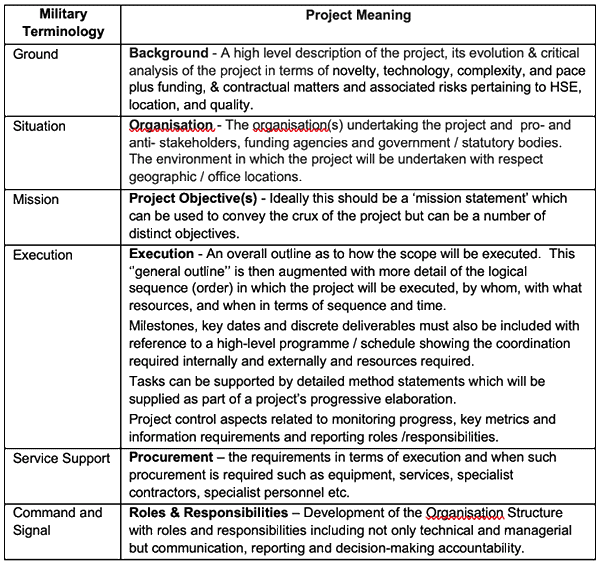

The various militaries around the world use orders to convey plans to their units and ensure that information is sent in unambiguous and accurate terms, precisely and on time. Standard formats are adopted so that issuers cover all aspects and receivers know what information will be conveyed. This is achieved through Operations Orders with a specific format and content. Of course, the effectiveness of orders depends on who has carried out the planning, who formulates them and who delivers them which is a matter of style and ability. However, the information required to be conveyed is in a tried and trusted format which can also be applied to a project:

Project Execution

But projects are not military operations some say. For some the military is all about “yes sir” and “no sir” and following orders blindly. A set of orders is a plan and, if things don’t go according to plan during an operation, then situation reports are issued advising of such deviations and orders are changed, for the most time, accordingly. One can’t always predict what will go right or what may go wrong but one can adapt, and when adaptation is needed the plan must be changed to suit the circumstances and new orders must be issued to confirm, clarify, or change the ongoing execution.

The military, like projects, requires reporting so that changing situations may be monitored and controlled. We learn of reality through monitoring and reporting so that mitigation may be applied on a regular basis. Daily, weekly, and monthly reports should provide information for decision making as opposed to meeting some ritualistic submission to meet a contractual compliance requirement. The Deming Cycle of Plan, Do, Check, Act is not just about quality control it’s about managing and communication. People on the ground need to be aware of what is required of them and just as importantly, how they should be operating if change occurs.

And change happens. It occurs as our socio-economic environments and political and legal frameworks adapt and evolve. It occurs due to inflation, deflation, availability of resources which includes people, equipment and raw materials. Change happens when actual progress is less than that planned as well as a host of other potential risks. Just look the COVID pandemic and changes to work. Look at the Ukraine crisis and the ripple effect of one countries economy on us all. Change is constant.

Project changes also occur because of variations to the scope of works, or the time frames for completion or quality requirements. Consequently, any initial plans must be changed to suit the changing internal and external and the initial Project Execution Plan may well be very different to the final, as executed plan and as-experienced project.

Conclusions

Communication is the most vital and necessary part of every project. Without communication requirements will not be conveyed, methodologies and schedules will not be visible, and the roles, responsibilities, and accountabilities of those involved in its delivery will be confused.

Communication on occasion will be ad hoc and unordered, sometimes unwanted, and sometimes unnecessary. However, the communication of a project’s Execution Plan should be structured which leads to understanding a project’s purpose and the assumptions upon which execution is based. The Plan should also define the what, why, when, how and who of project reporting. Reporting, that timely transmission of information, allows the uncertainties of planning assumptions to be verified and validated.

If things go wrong as a consequence of change then, through effective and efficient communication, rather than chaos and confusion then appropriate action can be planned. And then…revised orders can be ordered in an orderly manner.

Bio:

Malcolm Peart is an UK Chartered Engineer & Chartered Geologist with over thirty-five years’ international experience in multicultural environments on large multidisciplinary infrastructure projects including rail, metro, hydro, airports, tunnels, roads and bridges. Skills include project management, contract administration & procurement, and design & construction management skills as Client, Consultant, and Contractor.

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.

Leave a Reply