In the realm of complex electromechanical systems, reliability allocation is a critical process that demands a delicate balance between safety, cost, and performance. As engineers, we are tasked with creating systems that not only meet functional requirements but also operate safely, efficiently, and cost-effectively over their intended lifespan. This article explores key strategies for optimal reliability allocation, emphasizing the importance of safety while considering economic factors and system performance.

The Foundation: Safety First.

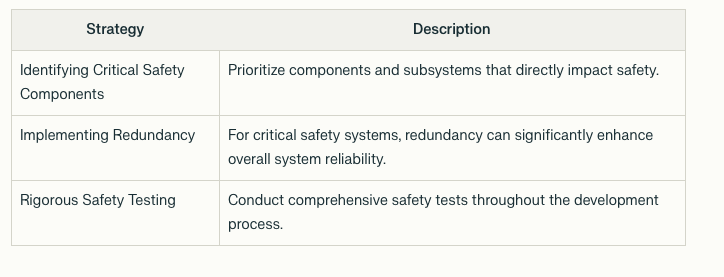

When allocating reliability in complex electromechanical systems, safety must always be the primary consideration. This approach not only protects users and the environment but also safeguards the reputation and longevity of the product and company. Safety-centric reliability allocation involves:

1. Identifying Critical Safety Components: Prioritize components and subsystems that directly impact safety.

2. Implementing Redundancy: For critical safety systems, redundancy can significantly enhance overall system reliability.

3. Rigorous Safety Testing: Conduct comprehensive safety tests throughout the development process.

Cost Considerations in Reliability Allocation.

While safety is paramount, cost considerations play a crucial role in reliability allocation. Balancing reliability improvements with associated costs involves:

1. Life Cycle Cost Analysis: Consider not just initial production costs, but also long-term maintenance and potential failure costs.

2. Cost-Benefit Analysis of Reliability Improvements: Evaluate the return on investment for various reliability enhancement strategies.

3. Optimizing Component Selection: Choose components that offer the best balance of reliability and cost.

Maintenance Strategy and Reliability.

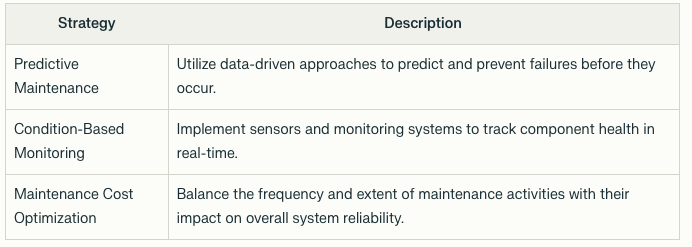

An effective maintenance strategy is integral to sustaining system reliability over time. Key aspects include:

1. Predictive Maintenance: Utilize data-driven approaches to predict and prevent failures before they occur.

2. Condition-Based Monitoring: Implement sensors and monitoring systems to track component health in real-time.

3. Maintenance Cost Optimization: Balance the frequency and extent of maintenance activities with their impact on overall system reliability.

Severity Impact and Occurrence: The FMEA Approach

Failure Mode and Effects Analysis (FMEA) is a powerful tool in reliability allocation. It helps in:

1. Assessing Failure Severity: Evaluate the potential impact of different failure modes on system performance and safety.

2. Estimating Occurrence Probability: Analyze historical data and engineering judgments to predict failure frequencies.

3. Prioritizing Mitigation Efforts: Focus resources on addressing the most critical failure modes first.

Early Detection of Degradation

Implementing strategies for early detection of system degradation is crucial for maintaining reliability. This involves:

1. Advanced Sensing Technologies: Employ state-of-the-art sensors to detect early signs of wear or malfunction.

2. Data Analytics and AI: Utilize machine learning algorithms to identify patterns indicative of impending failures.

3. Regular System Health Checks: Implement scheduled diagnostics to catch potential issues before they escalate.

Optimizing Reliability Allocation

To achieve an optimal balance in reliability allocation, consider:

1. System-Level Approach: View the system holistically, understanding how individual component reliabilities contribute to overall system performance.

2. Iterative Design Process: Continuously refine reliability allocations based on testing results and operational feedback.

3. Stakeholder Collaboration: Engage with all stakeholders, including design, manufacturing, and maintenance teams, to ensure a comprehensive approach to reliability.

Conclusion

Effective reliability allocation in complex electromechanical systems requires a multifaceted approach that prioritizes safety while carefully considering costs, maintenance strategies, and performance impacts. By employing tools like FMEA, implementing robust early detection systems, and adopting a holistic view of system reliability, engineers can create systems that are not only safe and reliable but also economically viable and high-performing

As we continue to push the boundaries of technological advancement, the importance of sophisticated reliability allocation strategies will only grow. It is our responsibility as engineers to stay at the forefront of these methodologies, ensuring that the systems we design meet the ever-increasing demands for safety, reliability, and efficiency in our complex, interconnected world.

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.

Leave a Reply