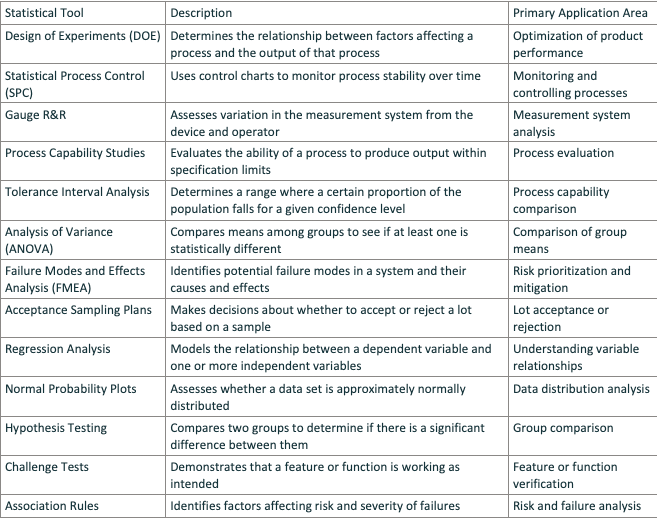

Statistical tools play a critical role in product validation, particularly in the automotive industry where ensuring quality, safety, performance, and reliability is paramount. The search results provide a wealth of information on various statistical tools and methods that are commonly used during the different stages of product validation. Here are some of the most frequently used statistical tools based on the provided sources.

Regression analysis is a statistical tool used to understand the relationship between a dependent variable and one or more independent variables. It is particularly useful in product validation for identifying and quantifying the impact of various factors on product performance or quality.

In product validation, regression analysis can serve several purposes:

1. Predictive Modeling: To predict the outcome of a product performance characteristic based on one or more input variables.

2. Understanding Relationships: To understand how changes in process parameters affect product quality.

3. Optimization: To optimize product design or process parameters for improved performance.

4. Risk Assessment: To assess the risk associated with certain product features or process settings.

There are multiple types of regression analysis, each suitable for different scenarios:

– Simple Linear Regression: Involves one independent variable and one dependent variable and assumes a linear relationship between them.

– Multiple Linear Regression: Involves multiple independent variables. It is used when the product performance is influenced by several factors.

– Logistic Regression: Used when the dependent variable is categorical, such as pass/fail in a product test.

– Nonlinear Regression: Used when the relationship between variables is not linear.

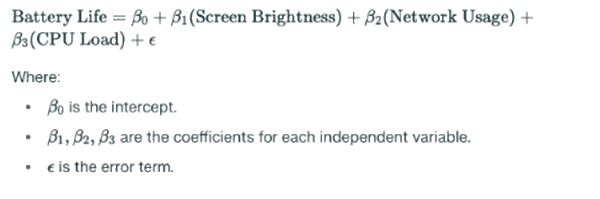

Consider a scenario where a company is validating the battery life of a new smartphone model. The dependent variable is the battery life (in hours), and the independent variables could include screen brightness, network usage, and CPU load.

Step 1: Collect Data

The company would collect data on battery life under various conditions of screen brightness, network usage, and CPU load.

Step 2: Perform Regression Analysis

Using multiple linear regression, the company could create a model that predicts battery life based on the independent variables. The regression equation might look something like this:

Step 3: Interpret the Results

The coefficients indicate the expected change in battery life for a one-unit change in the independent variable, holding all other variables constant. For example, if beta_1 is -0.5, it suggests that for every unit increase in screen brightness, the battery life decreases by 0.5 hours, assuming network usage and CPU load remain constant.

Step 4: Validate the Model

The company would validate the model by comparing the predicted battery life against actual observed data. If the model has a good fit, it can be used to optimize the product for better battery life.

Regression Fit to Distribution

A regression fit to a distribution involves plotting the observed data and the predicted values from the regression model to assess how well the model fits the data. A good fit would show that the predicted values are close to the observed data points.

For instance, if the company plotted the observed battery life against the predicted battery life from the model and found that the points lie close to the 45-degree line (where observed equals predicted), it would indicate a good fit.

Conclusion

Regression analysis is a powerful tool in product validation, allowing engineers and researchers to quantify relationships between variables, make predictions, and optimize product features. By understanding and applying the appropriate type of regression analysis, companies can improve product quality and performance, ultimately leading to more reliable and successful products.

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.

Leave a Reply