Condition Monitoring when used to drive reliability improvement offers diagnostics, information and data for Root Cause Analysis and equipment redesign, along with verification of defect or design correction.

Condition monitoring applied proactively is a context embracing world class reliability maintenance concepts.

Where condition monitoring is used as a proactive defect elimination strategy to drive failure prevention the benefits really add up with improved Reliability giving extended Mean Time Between Failures and additional Plant Availability. There have been recorded instances where the gains in improved plant uptime has lead to deferment of expensive plant expansion.

Keywords: proactive condition monitoring, failure prevention, defect elimination

1. Condition Monitoring

A Definition of Condition Monitoring: The process of systematic data collection and evaluation to identify changes in performance or condition of a system, or its components, such that remedial action may be planned in a cost effective manner to maintain reliability.

While the basic definition of Condition Monitoring (CM) may have general application across many industries, the objectives for Condition Based Maintenance (CBM) may vary greatly.

- CM uses selected measurements to detect changes in operating conditions.

Many failure modes have measurable responses and develop over periods of time. These are the ideal applications for CBM. Sampling may be continuous, (eg turbo-machinery) or periodic ( eg monthly survey on conveyor drive). - CM gives early warning of potential failure.

If the measured parameters are well chosen and properly measured and analysed, there will be valuable information gained for maintenance planning purposes. It is essential that what defines ‘normal’ is understood and documented so that the severity of variations can be measured. - CM gives information about the nature of the failure.

From this a prognosis should be able to be determined. The rate of sampling and access to maintenance history on the machine may have an influence on the quality of the final decisions made. - CM allows management of failure to full life potential.

Identification of a failure mode does not necessarily mean that an immediate maintenance action is needed. Just when maintenance action must be taken is the toughest part of managing a CBM programme! Your reputation may depend on it!! The best course is to involve as many informed people in the decision making process. - CM evaluates corrective action.

Immediately after a machine has been repaired it should be subject to condition monitoring testing. This will potentially identify assembly or installation faults that may lead to early failure (infant mortality) or affirm the quality of improvement achieved through the application of improved work practices or maintenance standards.

The most commonly used techniques of condition monitoring are;

- Vibration Measurement and Analysis

- Oil Condition and Wear Debris Analysis

- Thermography

- NDT, especially thickness testing

- Performance trending, e.g. flow rate measurement

The developing focus is upon integrated condition monitoring giving better forecasts of remaining life. Of these, vibration is the most widely used and lends itself to detection of a wide range of faults.

Oil analysis is a particularly powerful technique for the monitoring of gearboxes and also reciprocating machinery.

The benefits of Thermography in surveys of electrical switchboards has long been recognized. It is now being used more widely for rotating equipment misalignment and wrong tolerance-and-fit problems. Operations personnel can use thermography to identify pipe blockages and sediment build-up in tanks where higher temperature fluids are involved.

2. Condition Monitoring in the Real World

There is a wide acceptance of Condition Monitoring, but there are a number of limiting factors, most coming from a historical context of the application being seen as the answer to all of maintenance’s needs;

- CM is often used as a ‘stand alone’ maintenance concept

- Frequently CM is simply used for Failure Prediction, little else is asked for or expected

- Too often CM has been driven from the bottom upward

- CM alone does not provide for reliability

- CM does not prevent failure – it detects and predicts it.

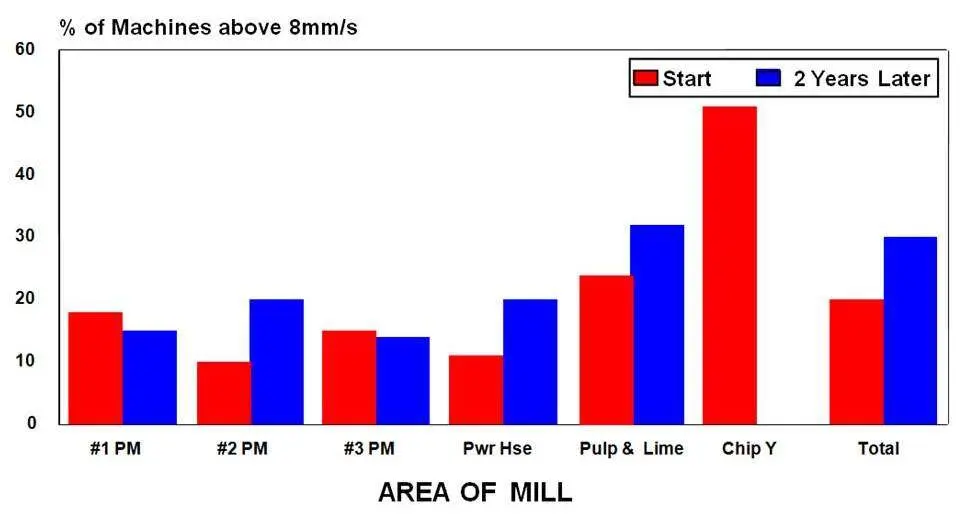

The following graph is a vibration history from a ‘successful’ condition monitoring programme and shows that some 50% more machines are running roughly after 2 years. The same old problems are appearing repeatedly and not being eliminated. They were ‘successful’ from a failure prediction perspective—they found a lot more problems, but the condition monitoring strategy was not supported with a defect elimination strategy!

This is not good from the perspective of maintenance costs, plant availability and reliability.

Some of the limitations of Condition Monitoring are quite reasonable and must be accepted as such;

- It can be expensive to apply,

- It is normally applied only where cost and Risk justifies it,

- It tends to be used on expensive and large plant.

Typically, in very many plants we find that only 20% – 30% of plant is covered by a monitoring programme. Unfortunately there are plants where Condition Monitoring is not working well; a major issue is the translation of data into information and that information being utilised correctly within the maintenance organisation to make good reliability improvement decisions.

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.

Leave a Reply