In the realm of mechanical engineering, the reliability and longevity of pumps are critical for numerous industrial applications. Predicting wear-out of pumps can significantly enhance maintenance strategies, reduce downtime, and optimize operational efficiency. One effective approach to predicting wear-out is by monitoring the revolutions per minute (RPM) of pumps over a large population and extended time periods. This article delves into the methodology of creating a wear-out prediction model based on RPM measurements.

Understanding Pump Wear-Out

Pump wear-out is a gradual process influenced by various factors, including mechanical stress, fluid dynamics, and operational conditions. Over time, components such as bearings, seals, and impellers degrade, leading to reduced performance and eventual failure. By monitoring RPM, we can gather valuable data to predict when a pump is likely to fail, allowing for proactive maintenance.

Developing the Wear-Out Prediction Model

1. Data Collection

The first step involves collecting RPM data from a large population of pumps. This data should be gathered continuously over an extended period to capture the full operational lifecycle of the pumps. Key data points include:

– RPM readings at regular intervals

– Operational hours of the pump

– Maintenance records detailing any repairs or replacements

– Environmental conditions such as temperature and pressure

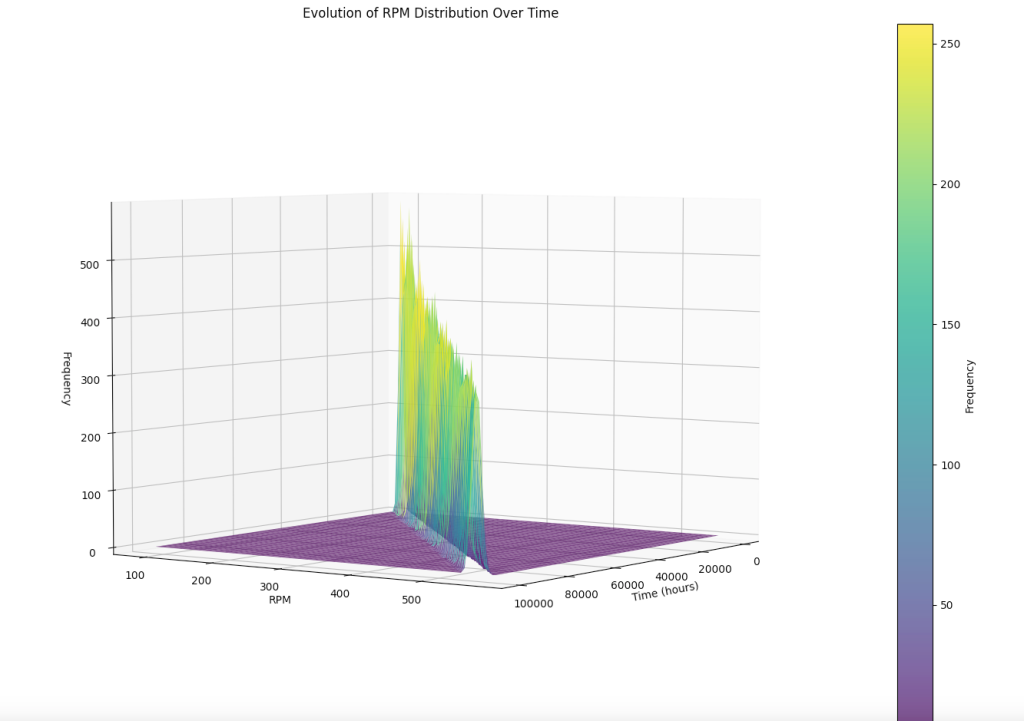

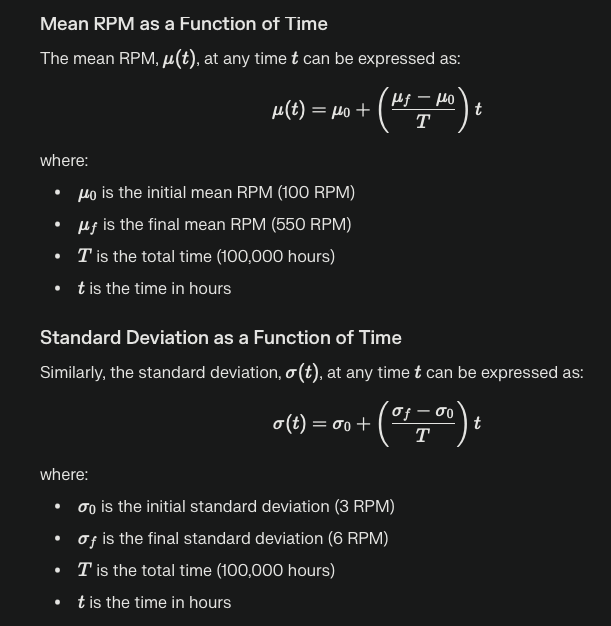

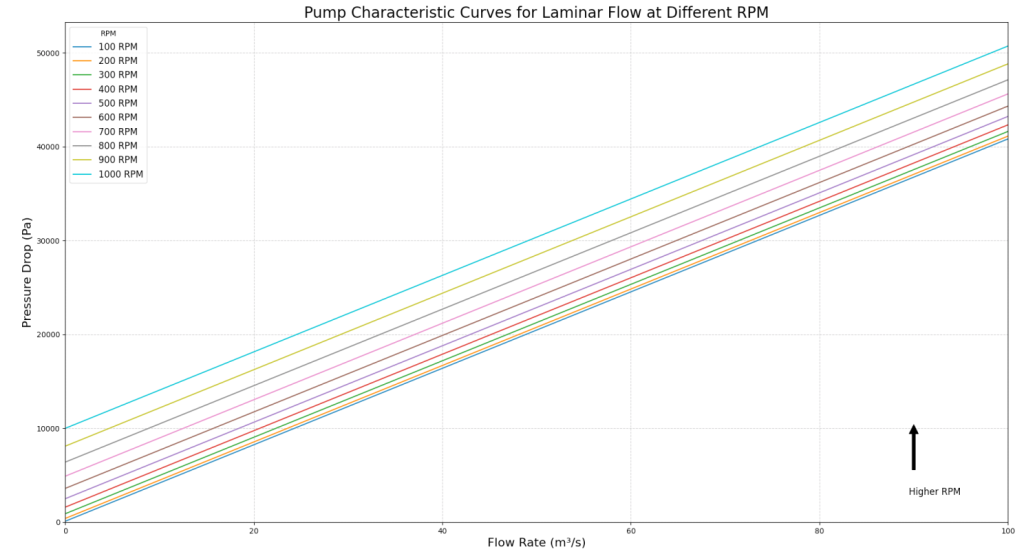

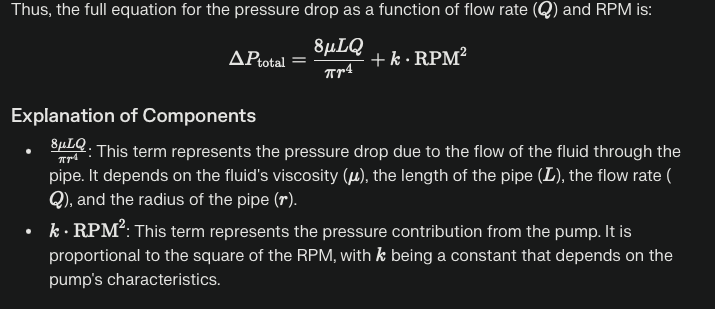

2. Data Analysis

Once the data is collected, the next step is to analyze it to identify trends and patterns. Statistical methods and machine learning algorithms can be employed to process the data. Key analysis techniques include:

– Time-Series Analysis: This helps in understanding how RPM changes over time and identifying any cyclical patterns.

– Regression Analysis: This can be used to correlate RPM variations with wear-out indicators.

– Anomaly Detection: Machine learning models can detect unusual RPM patterns that may indicate impending failures.

3. Model Development

Based on the analysis, a predictive model can be developed. This model should be capable of forecasting the remaining useful life (RUL) of the pump based on current and historical RPM data. Commonly used models include:

– Proportional Hazards Models: These models assess the risk of failure at any given time, considering the influence of RPM and other variables.

– Survival Analysis: This technique estimates the time until a pump failure occurs, based on the observed RPM data.

– Neural Networks: Advanced machine learning models like neural networks can learn complex patterns in the data and provide accurate predictions.

4. Model Validation

The predictive model must be validated using a separate dataset to ensure its accuracy and reliability. This involves comparing the model’s predictions with actual wear-out events and adjusting the model parameters as needed.

5. Implementing the Model

Once validated, the wear-out prediction model can be integrated into the maintenance management system. This allows for real-time monitoring and alerts, enabling maintenance teams to take proactive measures before a pump fails. Key implementation steps include:

– Setting Thresholds: Define RPM thresholds that trigger maintenance actions.

– Automated Alerts: Configure the system to send alerts when the model predicts an impending failure.

– Maintenance Scheduling: Use the predictions to schedule maintenance activities during planned downtimes.

Conclusion

Predicting pump wear-out using RPM measurements is a powerful approach to enhancing pump reliability and operational efficiency. By collecting and analyzing RPM data over time, we can develop robust predictive models that provide valuable insights into pump health. Implementing these models allows for proactive maintenance, reducing downtime and extending the lifespan of pumps.

As we continue to advance in data analytics and machine learning, the accuracy and reliability of wear-out prediction models will only improve, making them an indispensable tool in the maintenance engineer’s toolkit.

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.

Leave a Reply