The Weibull distribution’s popularity across various industries stems from its remarkable flexibility and adaptability in modeling a wide range of data types, especially in reliability engineering and failure time analysis. This versatility is primarily due to the Weibull distribution’s shape parameter, which allows it to model different failure rates over time, aligning closely with the real-world behavior of many systems and components.

Flexibility and Shape Parameter

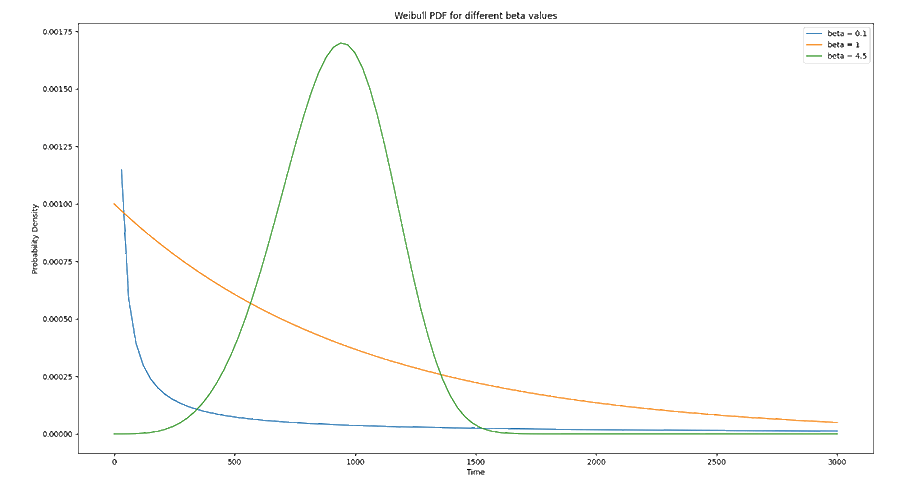

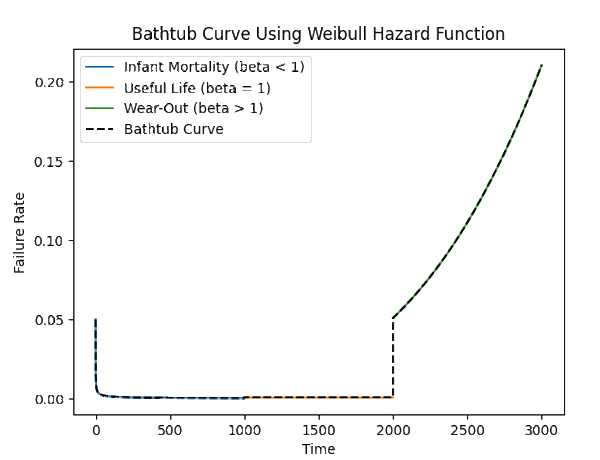

The Weibull distribution can take on various shapes depending on the value of its shape parameter (often denoted as β or k). This shape parameter allows the Weibull distribution to model different types of failure rates:

- Decreasing failure rate (β<1): Characteristic of “infant mortality,” where failures are more likely to occur early in the product’s life.

- Constant failure rate (β=1): Corresponds to a random failure rate over time, similar to the exponential distribution.

- Increasing failure rate (β>1): Indicates “wear-out” failures that occur more frequently as time progresses.

This ability to model various failure rates makes the Weibull distribution particularly useful for reliability analysis, where understanding the pattern of failures over time is crucial for maintenance planning, warranty analysis, and life data analysis.

The Weibull distribution is a cornerstone in reliability analysis, helping engineers model and predict the time to failure of components and systems. This is particularly important in industries where reliability is critical, such as aerospace, automotive, and electronics. For instance, it has been used to model the time to failure of aircraft engines, where understanding the wear-out phase is crucial for maintenance planning and safety assurance.

By analyzing failure data through Weibull plots, engineers can predict when a product is most likely to fail and schedule preventive maintenance accordingly. This helps in optimizing maintenance schedules, reducing downtime, and extending the lifespan of equipment. The ability to plan maintenance based on actual data rather than on fixed intervals can lead to significant cost savings and increased reliability.

The Weibull distribution aids in determining the life-cycle cost of products by forecasting failure rates over the product’s lifespan. This information is crucial for setting warranty periods and understanding the long-term financial implications of product failures. Manufacturers can use this data to balance the cost of extended warranties against the expected reliability of their products.

In materials science, the Weibull distribution models the strength and reliability of materials under stress. For example, the distribution can predict the probability of a metal breaking under different loads, which is essential for designing materials that meet safety and performance standards. This application is vital in industries such as construction, automotive, and aerospace, where material failure can have severe consequences.

Life testing involves subjecting products to various conditions to measure their failure rates over time. The Weibull distribution models these failure rates, helping engineers understand how products will perform under real-world conditions. This is crucial for validating the design and reliability of products before they are brought to market.

In risk management, the Weibull distribution assesses the probability of system or product failure under different conditions. This application is essential for industries where failure can lead to significant financial loss, environmental damage, or endanger human lives. By understanding the risk of failure, companies can implement strategies to mitigate these risks.

The Weibull distribution models wind speed data, which is crucial for the design and optimization of wind energy systems. By fitting a Weibull distribution to wind speed data, engineers can estimate the probability of certain wind speeds occurring at a location, which helps in selecting sites for wind farms and designing turbines for optimal energy production.

In summary, the Weibull distribution’s versatility and ability to model different failure rates make it an invaluable tool in reliability engineering. Its applications span across various industries, enabling engineers to predict failures, plan maintenance, analyze life-cycle costs, design materials, conduct life testing, manage risks, and optimize wind energy systems.

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.

Leave a Reply