By Mike Freier

In the last blog, we discussed the importance of business systems including the perils of manual processes, common business systems used for an agile hardware product lifecycle, optimizing data flows, managing product data across systems, and tips for success.

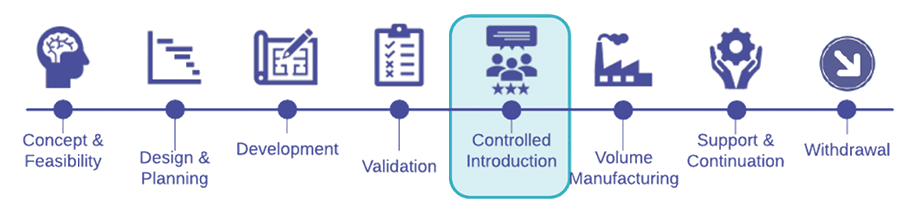

Now, in this final blog in the controlled Introduction series, we discuss the importance of customer trials, identifying and developing trial customers, running the trials and how to leverage the learnings resulting from these trials to benefit your business.

The Importance of Customer Trials

Not to be confused with earlier prototype testing (during the development phase) where potential customers are invited to try out your product and provide feedback on the product direction, customer trials are conducted to gather early feedback on the whole product from a small, controlled group of users, before signing off on volume production. When managed effectively, these trials can foster long-term customer relationships and generate a positive network effect surrounding both the product and your company. These specially chosen customers offer valuable perspectives on product fit, utility, and overall value, which encompasses after-sales support and services, therefore, it’s crucial to plan these interactions with trial customers early in the development process.

You should try to incorporate as many of the customer-affecting activities shown in the diagram below from the trials ecosystem to ensure you have the best possible coverage of the customer experience before you embark on volume production.

Identifying and Developing Ideal Trial Customers

Selecting trial customers may seem straightforward, but it’s essential to choose customers who are open to using an early product version, despite potential shortcomings, such as missing parts or inadequate documentation. These customers should be eager to partner with you to refine the product before full-scale manufacturing begins and the product reaches a broader market. As a reward, they will get the first chance to use your new product. You may also consider offering them exclusive pricing to boost uptake.

Start early by outlining the ideal trial customer profile for your sales team during the validation phase when you gain confidence in the product’s performance.

Be precise when specifying trial customer requirements, thus preventing the sales team from merely selecting their favorite clients. Selection criteria might include payment structure, commitment to trial support, prompt communication of successes and failures, willingness to endorse the product publicly (testimonials, press releases, etc.), and readiness to place volume orders after the trial.

Interview potential trial customers, clearly communicating expectations and the product’s current state. Aim for a manageable number of customers to avoid being overwhelmed by incoming information during the trial. In addition, select only the customers you believe will offer the most productive interactions and problem-solving collaboration. Once selected, you should maintain clear communication with these customers throughout the validation and manufacturing stages, updating them on potential delays or issues.

Running the Customer Trial

Once your contact manufacturer has completed production of the trial units, you’re ready to begin validating the processes and systems to ensure seamless delivery to the trial customers.

Consider the following key areas for evaluation during your trial run:

- Order Process: Test whether a trial customer can seamlessly place an order through your sales systems. Does this order then initiate a delivery process?

- Logistics Process: Does the previously placed order trigger a logistics operation that ensures the product reaches the customer?

For these two areas, you might opt to simulate the order and shipping processes. After confirming that they are generated correctly in the system, you can hand-deliver or otherwise ensure the products reach the customer’s trial team.

- Customer Setup: Is the customer able to independently install, configure, and start using the product with the included instructions? It’s crucial to observe and document any discrepancies or issues for future improvements. However, resist the urge to “assist” the customer during this phase, as it could obscure potential gaps in your instructions.

- Customer Usage Trials: This involves a continuous product usage period, ideally involving both user and company-provided test scenarios. Open communication between your trial team and the customer’s team is crucial here regarding any observations, issues, changes, or configuration adjustments.

Wrapping up the Trial

Following the trial phase, it’s crucial to gather all data, findings, and insights to share with your marketing, engineering, manufacturing, and other relevant departments, such as user guide developers or web team. This data will guide decisions about which aspects to improve, which to leave as they are (with customer-facing mitigation strategies or workarounds), and when to initiate volume manufacturing. To complete the trial, you should hold update meetings with your trial customers to let them know how you are incorporating their feedback, and to maintain a strong relationship as you move forward into volume production.

In conclusion, early customer trials offer a valuable opportunity to understand your product from the customer’s perspective, enabling you to make informed decisions that best serve your company and product. While some businesses may opt to launch with known imperfections, managing customer expectations along the way, others may choose to resolve all identified issues before contacting their mainstream customers. Remember, there’s no one-size-fits-all approach here; the choice depends on your product and market strategy.

###

About the Author

Mike Freier is a Founder and Principal Consultant at the Product Management Consulting Group Inc. He has 20+ years of experience with high-tech companies, including more than a decade in product management and product marketing. He was a long-time board member and President of the Silicon Valley Product Management Association, served on the MIT-Stanford (VLAB) executive planning committee and spent several years mentoring start-up founders at the Cleantech Open. Mike graduated from the University of Massachusetts at Amherst with a BSME degree.

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.

Leave a Reply