John Fincham was master shipwright at Chatham and Portsmouth, and the superintendent of the school of naval architecture. He wrote several books about shipbuilding and construction of masts. In 1851, he wrote a history of naval architecture. His history recorded some design changes that the Royal Navy made in the 1700s to improve the reliability of its ships. These changes were important and permanent enough for Fincharm to discuss them 100 years later.

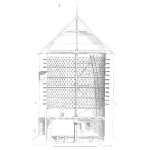

Stagnant bilge water was known to accelerate hull rot. In 1715, a new system of channeling bilge water within the hull was introduced. These changes were channels that used the ship’s motion to circulate bilge water and air around the keelson, which fought stagnation. The changes also included a drain channel (the “limber course”) to allow bilge water to drain easily to the bilge pump. Otherwise, it would be retained in pockets that were formed by the ships structure. This became a standard design feature of British naval and merchant ships.

Fincham discussed an experiment conducted in 1719. Ships in storage had a tendency to rot faster, and hot summer weather was thought to accelerate the rotting. In the experiment, the bilge was flooded with several feet of water in the summer months. The water was theorized to keep the hold cooler, retarding the rate of rot.

1719 also saw “reconsideration” of “preservation of timber used in the building of ships.” In spite of having two hundred years of shipbuilding experience, the navy was still trying to improve the harvesting, storage, and preparation of timber so that the finished ship would have a long service life without being rebuilt several times. The effort would continue for more than another century. Fincham commented, “The same subject had been brought under the notice of the navy board in the years 1694, 1697, 1703, 1704, 1715, 1716, and 1717.” This shows that navy administrators continued to search for improvements over a long period.

In the early 1700s, two methods were used to prepare timber for construction: charring and stoving. Both were intended to increase durability and formability of the timber. In Fincham’s description, stoving consisted of heating timber in wet sand. Charring was burning the first inch of depth to carbonize it. The navy conducted an experiment in 1720 by building with different materials. HMS Falkland was rebuilt using planks that had no preparation, planks that were stoved, planks that were charred, and planks that were both stoved and charred. In 1726, HMS Falkland was reexamined. The different preparation methods were compared with the extent of decay and repairs required. As a result, stoving became the preferred preparation method.

Stoving was practiced until 1736. Steaming became standard for the next 8 years, then the dockyards switched to using kilns. Each of these changes in construction method was intended to improve the reliability of ships and reduce the maintenance requirements. The changes also had to be coordinated with changes to the preparation facilities across multiple construction yards.

Fincham related other experiments to determine which compositions of tar and pitch were most effective on wood sheathing. The mixture had to prevent damage from mulloscs, but also prevent growth of marine plants. By 1737, the navy selected a standard mix.

In the early 18th century, the Royal Navy knew that the air exhaled by the crew formed carbonic acid. At the time, carbonic acid in the bilgewater was thought to accelerate hull rot. Fincham wrote that the damage from carbonic acid in the bilge due to the exhaling crew continued unabated until 1753. The navy had long recognized the need for better ventilation, but did not have practical forced ventilation machinery. Beginning In 1753, windmills and air pumps were used to ventilate the lower parts of a ship. Fincham claimed that the “durableness of ships was materially improved” until the system fell out of use in 1798.

The navy had already conducted experiments in the 1670s to assess the corrosion of iron in lead-sheathed ships. These experiments were large, requiring the use of several ships, and took several years to complete. Fincham’s 1851 history showed that the naval bureaucracy in the early 1700s could also organize long-term experiments. Fincham wrote that that the goal of these experiments was to reduce specific failure mechanisms related to maintenance. He was writing from a position of some influence, as a shipbuilder and the head of the school of naval architecture. The 1851 history shows that the 19th century British naval establishment was aware of lessons about maintenance and reliability passed down from the prior 200 years.

References

Fincham, John A History of Naval Architecture: to Which Is Prefixed, an Introductory Disertation On the Application of Mathematical Science to the Art of Naval Construction. . London: Whittaker and co., 1851. https://hdl.handle.net/2027/hvd.32044044835676

An illustration of a relatively modern “limber course” can be found on pg 445 of the 1920 book Shipbuilding Cyclopediaby Webster, Phillips, and Haag. https://www.google.com/books/edition/Shipbuilding_Cyclopedia/fK8fAAAAMAAJ?hl=en&gbpv=0

Leave a Reply