Article by Mike Freier

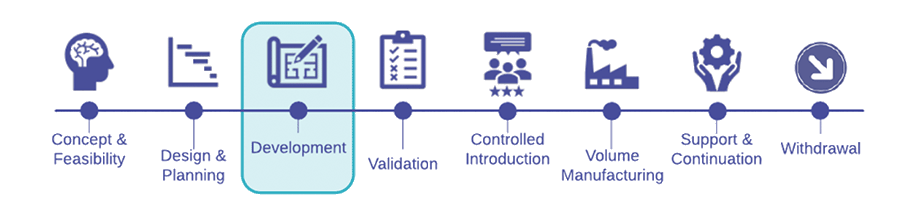

Manufacturing is an essential step in a new product launch that requires a thoughtful strategy. In this stage, teams define a manufacturing strategy, create a development schedule, and built units to test.

Development and Manufacturing Strategy

Depending on your company’s expertise and resources, you could develop a hardware product using an in-house, an outsourced, or a hybrid development model. For instance, some companies prefer to vertically integrate to control cost and quality, other firms, however, might outsource all development (or manufacturing) and keep their manufacturing and operations teams small. Another option is to use in-house or core resources to develop technology that has significant IP and then partner with other companies to develop and integrate supporting products, solutions, or technology.

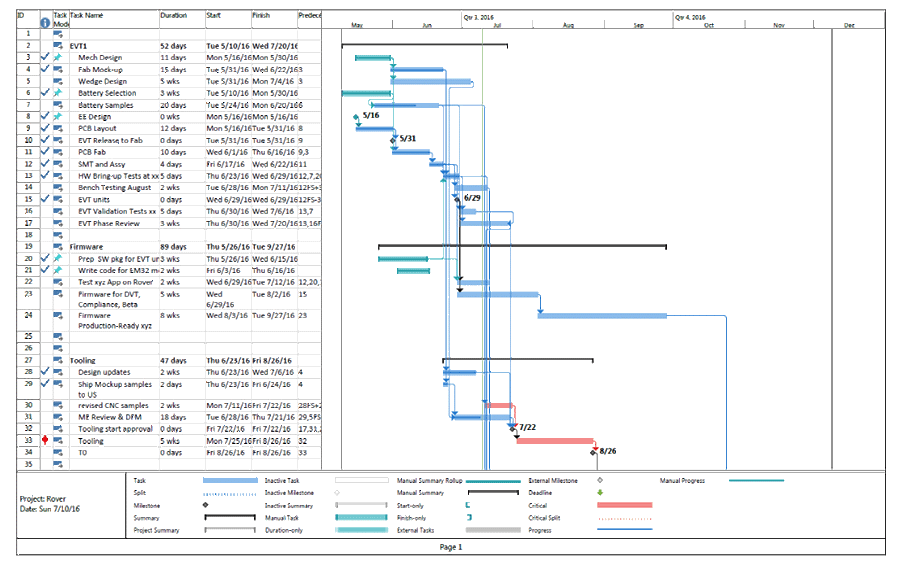

Development Schedule

Creating a schedule that captures key milestones is an important step in the product development process. As a general rule, the more complex a product is, the more valuable a detailed schedule becomes.

Benefits of a Schedule

- Enable your mechanical engineering, electrical engineering, and software teams to estimate the amount of time for each task

- Aggregate information and look for ways to reduce schedule (e.g., use parallel, not serial, tasks)

- Estimate the duration and timing for product validation and regulatory testing

- Capture major milestones for the entire project

- Show dependencies between critical items

- Demonstrate the relationship between sub-assemblies and final product testing

- Enable visibility and transparency across your entire cross-function or concurrent team

Build Engineering Units

Congratulations! After hundreds of hours of hard work, your team has completed the design for your first product, and it’s time to build a couple of units for engineering test. Working with actual hardware, your team is able to validate how each part goes together and start some basic functional testing.

If changes are required to improve your design, that’s okay. Despite best efforts and state-of-the-art design tools, there is always room for improvement. Especially when DfX is an important part of your company culture. The last blog post, described how to optimize the design of a product to achieve the best combination of assembly, cost, manufacturing, test, service, and supply chain.

Ship Beta Units

Now that you have a working prototype and have made some (minor) design changes, it’s time to build a few beta units. Beta units should be representative of what a production product looks like, with the understanding that more work is required before it becomes a production release and sellable. Give the beta units to your cross-functional partners to receive essential feedback and validate that your product meets your goals.

Example Beta Unit Allocation

- Validation

- Regulatory

- Reliability and life testing

- Demonstration unit (in-house)

- Sales demonstration unites (customer sites)

In the next blog post, we will cover validation and the steps to ensure your product meets the requirements and specifications covered earlier in this process.

About the Author

Mike Freier is a Founder and Principal Consultant at the Product Management Consulting Group Inc. He has 20+ years of experience with high-tech companies, including more than a decade in product management and product marketing. He was a long-time board member and President of the Silicon Valley Product Management Association, served on the MIT-Stanford (VLAB) executive planning committee and spent several years mentoring start-up founders at the Cleantech Open. Mike graduated from the University of Massachusetts at Amherst with a BSME degree.

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.

Leave a Reply