Maintenance and reliability problems are not new. Our forefathers and ancestors understood the value of smart maintenance and high reliability. They learnt from experience and passed their knowledge down to us through parables, stories, and sayings. The timeless advice of our forbearers on successful maintenance and reliability is as applicable to us now as it has been to every generation since the dawn of civilisation.

Keywords: Preventive maintenance, condition monitoring, work quality assurance, quality control

Maintenance was created when mankind first wore animal hide for protection from the weather and injury and used tools to do work. Since civilisation started the problems of poor quality and poor reliability have been with us. The hides we wore aged and perished and the tools we used blunted and broke. Along with the benefits of civilisation we also took on the obligation of its up-keep.

Maintenance and reliability protect us. Safety, defence, risk reduction, quality are benefits we need from maintenance and reliability. Our ancestors wanted those benefits too and laboured to get them. They learned what was needed to reduce maintenance and reliability problems and passed the fundamental understandings from generation to generation in wise words said to their children.

Across millennia of experience and experimentation sound and valuable advice on the best maintenance and reliability practices to use was passed to us from our forbearers and ancestors. Their advice is priceless and ageless. It is wisdom spoken with the lovingly hope that listeners will use the learning to improve their life and position. Below are explanations of five of the most important sayings our forbearers told us about having reliability and maintenance success.

“An apple a day keeps the doctor away.”

This reliability insight is one of the greatest health and wellness advices of all time. The wisdom it contains is not about the fitness benefits of eating apples. The understanding shrewdly conveyed in the saying is of the great worth of prevention rather than cure. Our forefathers tell us that the wise person adopts those actions and behaviours that extend their health and well-being and so prevents future illness and loss.

When this phrase was coined a visit to the doctor could mean your death. By the time you had deteriorated to the point a doctor was needed your chances of living had diminished greatly. It is a warning that maintaining good health is a life and death matter. It is smart maintenance.

In our world and time we know this saying as proactive maintenance. Many people think that it is a new way to do maintenance. It has always been the right way to do maintenance. Somehow we forgot what had been known for centuries. Now that we have rediscovered it we think we are wiser than our forbearers and understand maintenance better. The truth is we ignorantly dismissed our ancestors‟ wisdom. Do not begrudge the effort and requirements needed to keep your plant and equipment in the condition to live a long and healthy life. With healthy equipment you can find great business success; without reliable equipment certain business failure eventually awaits you.

magnificent advice out of our lives. No more will there be wise and patient mothers talking to their sons and daughters about good maintenance practices and the smart ways to stop problems and save money and time. I worry we are heading toward great technological disasters because mothers no longer make and repair clothes and so cannot train and teach their children about the need for vigilance.

“When all you have is a hammer, everything begins to look like a nail.”

There is a powerful warning in this saying about the dangers of ignorance and stymied education. If we know too little we risk misunderstanding the truth. If we know too little we limit our range of decisions and solutions. If we know only a few things we cannot be successful in those situations where those few things no longer apply.

Our loving ancestors must have made many mistakes and learned this truth at great cost to them to have arrived at advice so profound and wise to give us. They clearly put high value on learning and understanding. They knew that ignorance and mistaken beliefs always lead to trouble.

Today the message is still relevant to us in industry. Perhaps it is more important than ever before. Our future is one of greater complexity. We drive technology to create ever more complex machines and systems. In an effort to build a sustainable civilisation we add machines with intricate functions to our world. These technologies and machines need people with a deep knowledge and understanding of what to do and the skills to do it masterly.

In your operation you need people that can use more than „a hammer‟ to look after the plant and equipment. What unimaginable trouble we would have if engineers, maintenance and operations people only know how to use „a hammer‟ and they were limited to only „hammers‟ in their toolkits. To be successful you need people with lots of different tools in their toolboxes who can use each masterly. Those toolboxes need to be full of clean, in-perfect-condition, well-practiced and properly-handled tools. Such skilled people with such toolkits will solve problems and not create them.

Improving education, knowledge and skills is a business success strategy; it is a life success strategy. Ignorance and the bravado it breeds are terribly expensive and wasteful. When it comes to education the advice passed down to us is to „eat an apple a day and keep the doctor away‟.

“Measure twice; cut once.” – The Carpenter’s Creed

The carpenters of the past knew a thing or two about doing great work. I guess once a profession has been around for ten thousand years all the good secrets get discovered. The Carpenter‟s Creed – measure twice; cut once – is not about cutting wood. It is about delivering quality workmanship and the use of failure preventing quality control. The master carpenters of the past have honoured us with this priceless advice to guide us in the right ways. They say to proof-check our actions before doing them. They advise us that if you want to be sure that what you do will go right then thoroughly check it before you do it. An example will help you understand their success secret.

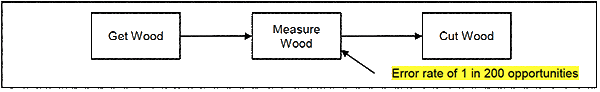

Taken literally the saying means that first you measure a required distance from a datum and put a mark. Then you check the mark is in the right place by repeating the measurement. We can draw logic diagrams of the work quality assurance method recommended by our forefathers. Figure 1 shows a process flow map of the first measurement. The human error rate in misreading a ruler or tape measure is about 1 in 200 opportunities. If you measured once and marked the wood it would be in the wrong spot on average 1 in 200 times. If you were the carpenter and cut the wood before you checked the position of the mark, you have a 1 in 200 chance that the cut is in the wrong place. A carpenter that did 40 to 50 cuts a day and only measured once before cutting the wood would scrap a job every week. Along with the wood they waste they also throw-out all the prior time, money and efforts put into it by others. Such a wasteful and uncaring carpenter would be of little use to an employer and would be given few career opportunities.

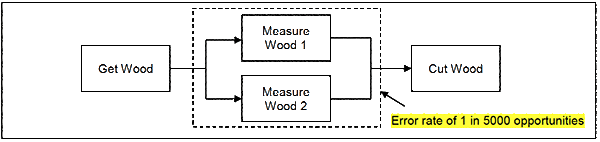

Figure 2 is a process flow map of our bygone carpenters‟ advice. With the added proof-check – the second measurement – the error rate falls to 1 in 5,000. Now work is scrapped only once in every 20 weeks. Those carpenters of the past knew a thing or two about doing masterly work.

Master carpenters across history warn that before committing it is best to “measure twice; cut once”.

“As above so below; as within so without.”

This is the oldest of the maintenance and reliability sages‟ sayings, coming from ancient Egypt of 5,000 years ago. It is about the effects of our habits, inner values, attitudes and deep beliefs on our behaviours and demeanour. As we are, so we do. Our mindset and spirit shows in our actions and in our lack of actions. This is true of organisations as much as it is of people.

We are counselled by the ancient Egyptians that our perceptions, inner values and state of mind conjure the outcomes that we experience. Your organisational knowledge, norms and culture make the people in your company behave as they do. These behaviours become its performance and then its results. From mind and heart through to result is a chain that binds our individual and company destiny.

In the world of engineering asset management, maintenance and reliability the wrong understandings, values and attitudes show-up as lost production, broken machines and failed equipment. Wrong mind and wrong heart ingrain wrong actions into business systems, repetitively producing plant and equipment failures. In such organisations formal and informal leaders build business processes and set work quality that can never deliver the performance wanted. If you want to understand why an operation performs badly and its maintenance is costly listen to what the leaders say. What they think becomes words. The words become decisions. The decisions become actions. And the people and company must receive the fateful consequences.

Maintenance and reliability success starts in the minds and souls of the formal and informal leaders in an organisation. The right knowledge, thoughts and attitudes flow into the leaders‟ decisions and from there into their words. Good words become correct actions and behaviours that reap good rewards. Wrong thoughts and incorrect behaviours can only reap wrong outcomes. Our ancient Egyptian cousins warn us that the reflected outcome can only be what is already within. The reason that a company does not have world-class maintenance and reliability performance is because the internal values and beliefs of its people are not yet world-class. World-class is first a mental journey to understanding. Our actions then follow our thoughts to world-class performance. Only then are world-class results certain to appear.

You can work the saying backward and first change the required outside behaviour so the inside values change in response. It takes dedicated persistence and commitment to continue the change process until there is nothing left of the old culture and norms. Usually people that don‟t adopt the new behaviours have to leave. The ancient Egyptians tell us that you can only change an organisation when its leaders have the vision and heart to rebuild it in the image that produces the required results.

Outcomes reflect the mind and spirit behind them. If you want a better future first instil the values and beliefs that create that future. In today‟s world of maintenance and reliability, as it has been since ancient times, seek and use the right knowledge and the right performance standards that will bring sure success. Nothing is new in maintenance and reliability, we have only forgotten to understand and use the powerful maintenance and reliability wisdom of our forefathers and mothers.

Mike Sondalini

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.

Leave a Reply