Burn-in testing is a critical reliability testing method used extensively in the electronics and electromechanical industries to identify and eliminate early-life failures in components. This process involves subjecting components or systems to normal or elevated stress conditions to accelerate the occurrence of latent defects. Here’s a detailed exploration of how burn-in testing works, its methodologies, and its importance in ensuring product reliability:

Purpose of Burn-in Testing

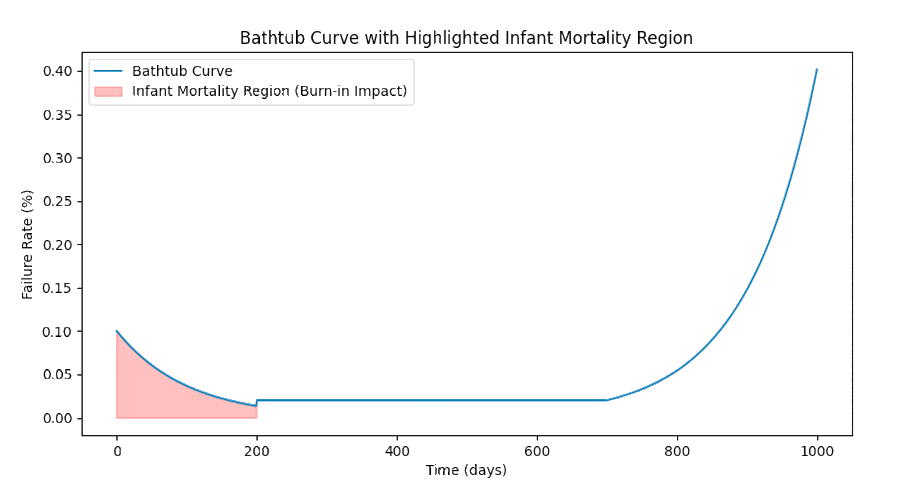

The primary goal of burn-in testing is to detect early failures, also known as infant mortality failures, in components before they are integrated into final products or shipped to customers. These failures typically occur due to defects introduced during the manufacturing process or inherent weaknesses in materials that manifest under operational stress.

To visualize the impact of burn-in testing on the infant mortality region of the bathtub curve using Python, we can use libraries such as matplotlib for plotting. Below is a Python graph a bathtub curve and highlights the infant mortality region where burn-in testing is typically focused.

Operating Conditions

Burn-in testing involves operating the component or system at elevated stress levels, which may include higher temperatures, increased voltage levels, or power cycling. These conditions are designed to be harsher than normal operating conditions to accelerate the aging process of the components, thereby precipitating failures.

The testing involves exposing components to conditions that are more extreme than those encountered during regular use. This includes thermal stress, voltage stress, and power cycling. Such stress testing helps in identifying potential failure modes triggered by extreme operating conditions, thereby allowing for the design and manufacture of more robust automotive components

Duration and Environment

The duration of burn-in testing can vary from a few hours to several days, depending on the component type, its application, and the historical failure data available. The testing environment is carefully controlled, often requiring specialized equipment such as burn-in ovens or chambers that can maintain precise temperature and electrical conditions.

Types of Burn-in Testing

Static Burn-in

Static burn-in involves applying constant stress conditions (like a fixed high temperature) without varying the operational state of the component. This method is simpler and less costly but may not fully simulate operational stresses.

Dynamic Burn-in

Dynamic burn-in is more complex and involves varying operational parameters during the test, such as changing voltage levels or toggling the component between different operational states. This type of testing is more representative of real-world conditions and can identify a broader range of potential failures.

Temperature effect during burn-in test:

1. Acceleration of Wearout Mechanisms

Elevated temperatures significantly accelerate the wearout mechanisms in semiconductor devices. These mechanisms include diffusion, electromigration, and oxidation, which are temperature-dependent. By increasing the temperature, the kinetic energy of atoms and the rate of atomic migrations increase, leading to faster aging and earlier manifestation of potential failures.

2. Activation of Latent Defects

High temperatures can activate latent defects that are not evident under normal operating conditions. These defects might include impurities, micro-cracks, and inconsistencies in material properties that were introduced during the manufacturing process. Under normal conditions, these defects might remain dormant for extended periods. However, elevated temperatures can cause these defects to expand or change, leading to electrical failures such as dielectric breakdowns, junction failures, or conductor open-circuits.

Benefits of Burn-in Testing

1. Early Detection of Failures: By identifying defects early, manufacturers can prevent defective components from reaching customers, thereby reducing warranty claims and enhancing customer satisfaction.

2. Improved Product Reliability: Products that have undergone burn-in testing are generally more reliable, as the process helps eliminate components that are likely to fail early in their lifecycle.

3. Cost Efficiency: Although burn-in testing requires upfront investment in testing equipment and time, it is cost-effective in the long run. It reduces the costs associated with field failures and recalls, which can be significantly higher than conducting burn-in tests.

4. Data Collection for Improvement: Burn-in testing provides valuable data about component performance under stress. This data can be used to improve manufacturing processes, component design, and quality control measures, leading to better overall product quality.

Challenges and Considerations

– Selection of Stress Levels: Determining the appropriate stress levels for burn-in testing is crucial. If the levels are too low, the test may not precipitate failures effectively. If too high, it may cause unrealistic failures that wouldn’t occur under normal conditions.

– Cost and Time: Burn-in testing can be time-consuming and expensive, especially for complex components. Balancing the depth of testing with cost and time constraints is a key challenge for manufacturers.

– Environmental Impact: The high energy consumption and potential waste generated from failed components during burn-in testing pose environmental challenges. Manufacturers must consider sustainable practices to mitigate these impacts.

In conclusion, burn-in testing is a vital process in the manufacturing of reliable electronic and electromechanical components. By stressing components early in their lifecycle, manufacturers can identify and mitigate potential failures, ensuring that only the most robust components make it into the hands of consumers. This not only enhances product reliability but also supports a brand’s reputation for quality.

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.

Leave a Reply