Predicting all failures in any system, including the automotive industry, is an inherently complex and challenging task. The inherent unpredictability of certain failure modes, coupled with the vast array of variables in operational environments, makes it impossible to foresee every potential failure. However, through strategic approaches and methodologies, it is possible to minimize major failures and reduce the infant mortality failure rate, thereby enhancing the reliability and safety of automotive products.

Minimizing Major Failures:

To minimize major failures, a multifaceted approach that incorporates both proactive and reactive strategies is essential.

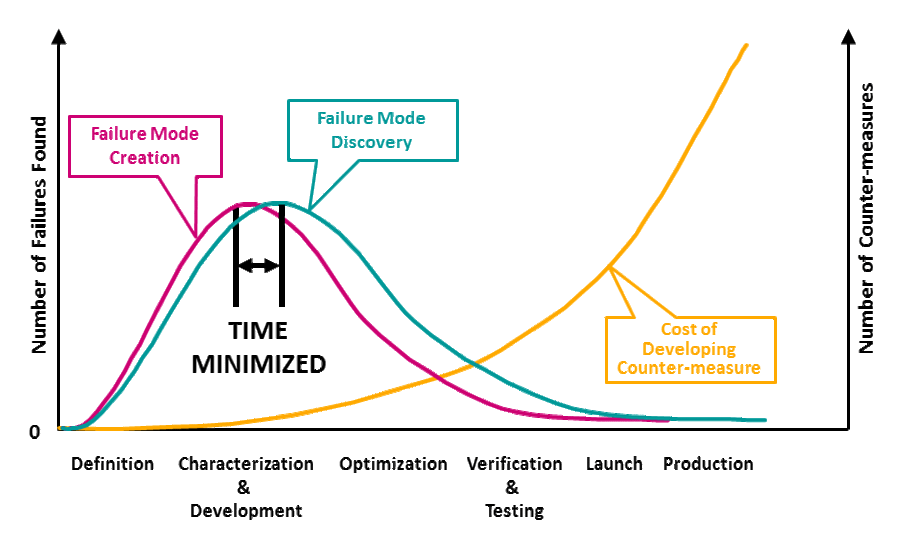

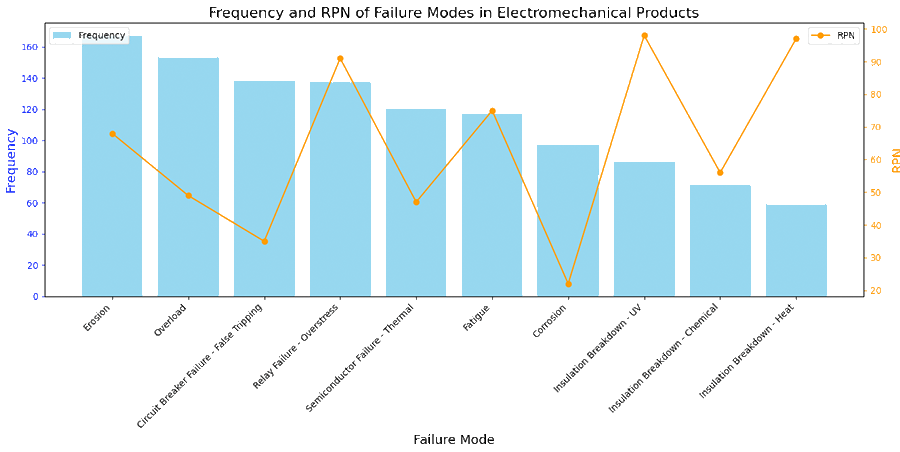

1. Failure Mode and Effects Analysis (FMEA):

FMEA is a systematic method for identifying potential failure modes, determining their effects on the system, and identifying actions to mitigate the risks associated with these failures. By analyzing components, assemblies, and subsystems, automotive engineers can prioritize failure modes based on their severity, occurrence, and detectability, and implement strategies to reduce their likelihood or impact.

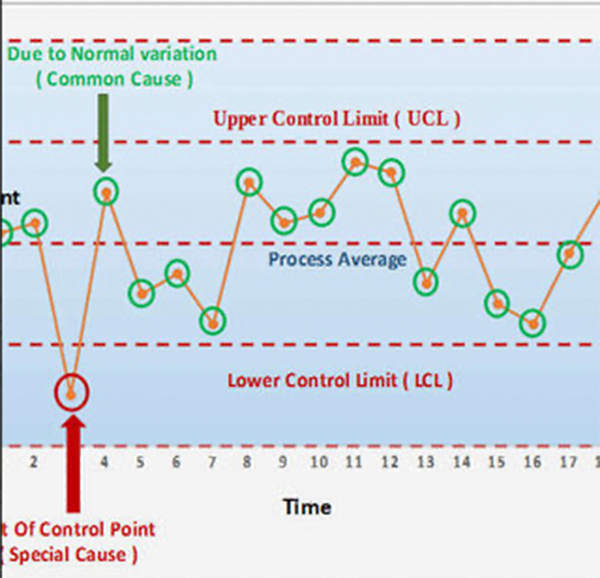

2. Predictive Maintenance:

Leveraging data analytics and sensor technology, predictive maintenance anticipates failure before it occurs. By monitoring the condition of equipment and analyzing data trends, it is possible to perform maintenance at just the right time to prevent unexpected breakdowns and extend the life of automotive components.

3. Quality Control and Testing:

Rigorous quality control and extensive testing of components and systems can identify and rectify defects before they lead to failures. This includes stress testing, environmental testing, and durability testing to ensure that automotive parts can withstand the conditions they will face in real-world operation.

4. Design for Reliability (DfR):

Incorporating reliability into the design process ensures that products are built to last. This involves selecting materials, designing for redundancy, and considering the worst-case scenarios in the design phase to enhance the overall reliability of the automotive products.

Reducing Infant Mortality Failure Rate

Infant mortality refers to failures that occur at the beginning of a product’s life cycle, often due to manufacturing defects or design flaws. Reducing the infant mortality rate is crucial for automotive manufacturers to ensure the reliability of new vehicles.

1. Enhanced Manufacturing Processes:

Implementing strict manufacturing controls and adopting advanced manufacturing technologies can reduce defects that lead to early-life failures. This includes automation, precision engineering, and real-time monitoring of production processes.

2. Burn-in Testing:

Subjecting components to burn-in testing, where they are operated under stress for a period, can help identify and eliminate early-life failures before the products are shipped to customers. This process helps in screening out defective units that are likely to fail early in their lifecycle.

3. Robust Design and Engineering:

Designing for robustness involves creating components and systems that are less sensitive to variations in manufacturing processes and operational environments. This can be achieved through tolerance design, material selection, and redundancy.

4. Early Field Failure Analysis:

Quickly identifying and analyzing failures that occur shortly after deployment can provide valuable insights into the causes of infant mortality. Implementing corrective actions based on these analyses can prevent similar failures in future products.

Different Types of Usage Leading to Different Failure Types

The operational environment and usage patterns significantly influence the types of failures that occur in automotive systems. For instance, vehicles operated in harsh environments, such as extreme temperatures or off-road conditions, may experience different failure modes compared to those used in mild, urban settings. Similarly, the intensity of use, such as frequent short trips versus long highway drives, can lead to different wear and stress patterns on components.

Understanding these usage patterns and designing vehicles and components to withstand specific conditions can help in reducing failures associated with particular operational environments. Tailoring maintenance schedules and recommendations based on usage types can also enhance reliability and safety for all users.

Summary:

In conclusion, while predicting all failures is not feasible, adopting a comprehensive and strategic approach that includes FMEA, predictive maintenance, quality control, and robust design can significantly minimize major failures and reduce the infant mortality rate in the automotive industry. Recognizing the impact of different types of usage on failure modes further allows for targeted strategies to enhance reliability and safety.

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.

Leave a Reply