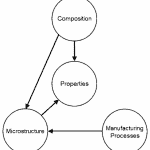

In the previous articles I discussed the component design process, the considerations for designing components, and the importance of leveraging materials engineering to design components that meet performance and reliability requirements at low cost.

I will start focusing on reliability, discussing the considerations for identifying component and joint reliability requirements. I will refer only to components for ease of writing and reading, but the discussion also applies to metallurgical joints, i.e. weld, braze, and solder joints.

In this article, I will discuss identification of the conditions that can cause degradation of the materials that comprise components and joints.

Reliability and materials

The materials that make up a product’s components can degrade due to exposure to use conditions. Steel screws corrode when exposed to water, some plastics become brittle when exposed to sunlight, and coatings on surfaces can wear away. For mechanical components degradation mechanisms include fatigue, creep, wear, corrosion, embrittlement, and others. For electrical components degradation mechanisms include dielectric breakdown, electromigration, and others.

The degradation leads to reduced capabilities of the materials and the components. If there is too much degradation, a component will stop functioning as required. This is a problem if it leads to reduction or loss of product performance before the end of a product’s expected life.

So, the reliability of a product depends on the extent of degradation of the materials that make up the product’s components. Identifying the conditions to which materials are exposed and selecting materials that can withstand the exposure is a critical part of designing products with good reliability. The remainder of this article will discuss identifying the conditions that can cause materials degradation.

Stressors

The conditions to which a component is exposed consist of stressors that act upon the materials during handling, shipping, and product use. A stressor can be…

- Mechanical such as static, dynamic, or cyclic loads; impact; rubbing

- Electromagnetic, such as applied voltage, current, or ultraviolet radiation

- Thermal such as elevated temperatures or temperature cycling

- Chemical, such as gases, solvents, acids, or bases

- Biological, such as bodily fluids

- Electrochemical when exposed to a corrosive environment

Sources of stressors

There are five sources of stressors: component functionality, environment, interactions with other components, minor abuse, and misuse.

Component functionality

Component functionality is related to the stressors directly related to a component’s functions. Examples are the mechanical loads on a motor shaft as the shaft moves another device and the electricity that passes through an electrical circuit. The motor shaft mechanical loads, if cyclical, can cause a fatigue crack to form and grow in the shaft, leading to fracture. The electricity that passes through a circuit can cause electromigration, leading to an open circuit.

Environment

Environment refers to the environment in which the component operates. Examples of environmental stressors are

- Corrosive liquids and fumes that can attack equipment in processing plants.

- High-temperature environments that can cause plastics to soften or breakdown or cause metals to undergo phase transformations.

For many products, the environmental conditions depend on a component’s location within a product. A component located within the passenger compartment of an automobile is not exposed to the same temperature and corrosion conditions as a component located in the engine compartment. The pan of a skillet is exposed to much higher temperatures compared to the handle.

Interactions with other components

Interactions with other components occur when components are in contact with each other or when a component outgasses a chemical that interacts with another component. Examples of interactions between components in contact are

- Gears wearing on each other.

- Galvanic corrosion between components made of different metals.

- Stresses between mated components due to differences in thermal coefficient of expansion of the materials comprising the components

Other types of interaction stressors are wear, rolling contact fatigue, crevice corrosion, heating, outgassed chemicals, and others.

Minor abuse

Minor abuse refers to stressors that are slightly excessive but expected during typical use. Examples of minor abuse include

- dropping a telephone from a short height onto concrete.

- driving an automobile over potholes.

- small chemical spills onto a motor.

Many products are expected to withstand some minor abuse without failing to meet its performance requirements.

Misuse

Misuse refers to stressors that far exceed those expected during typical use. Products are not expected to be designed to be able to withstand abuse. For example, it is unrealistic to expect a cell phone to function properly after using it to hammer a nail into a wall or dropping it in a toilet. Or expecting a sedan to function properly after driving it through water two feet deep.

Identify magnitude of stressors

After identifying the stressors, the next step is to determine the magnitude of each. This can be done by direct measurement or modelling.

Guessing is another approach, but one that comes with downsides. Guessing too low means components won’t have the reliability needed for the product. This approach may be acceptable if two conditions are met. First, if reliability testing is used in conjunction with iterating component designs until they pass testing. Second, if there is enough time and budget built into product development to handle the testing/redesign iterations.

Guessing too high may mean components cost more than necessary to meet the product’s lower reliability needs. This approach may be acceptable if it enables passing product reliability testing the first time – avoiding redesigns – and launching a product on time or earlier.

There are upsides to guessing – the money and time saved measuring or modelling stressor magnitude.

No stone unturned

Identifying all the stressors acting on a component is critical for designing components that have the necessary reliability. The information is needed to identify the appropriate component form and materials. Going through the process properly requires a solid understanding of how components are used and the conditions to which they are exposed. FMEA is a good tool for helping to identify the critical components that require more attention and to identify all the stressors. Working with a materials engineer will help the process.

Not identifying all the stressors and their magnitudes early in product development adds uncertainty to the design process, which is stressful. The stress only builds as time goes on and design decisions must be finalized. I worked on a project for a custom product and the customer did not have information about the corrosive liquid that was going to be in contact with the product. The uncertainty dragged out for months and required consideration and testing of a very expensive material to deal with the worst-case scenario. The uncertainty consumed lots of engineering time. It was eventually determined that the corrosive liquid was not as bad as the worst-case scenario.

Reliability testing

After determining the stressors and their magnitudes it’s possible to identify and develop test procedures to evaluate component and product reliability. Future articles will cover testing, different stressors, and failure mechanisms.

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.

Leave a Reply