Design for Reliability (DfR) is a critical aspect of the product development process, particularly for electromechanical products where the interplay between electrical and mechanical components can introduce complex failure modes. DfR is a systematic approach to ensuring that a product is reliable over its intended lifespan and under the conditions it will face during use. It involves a variety of techniques and practices aimed at identifying and mitigating potential failure points early in the design process.

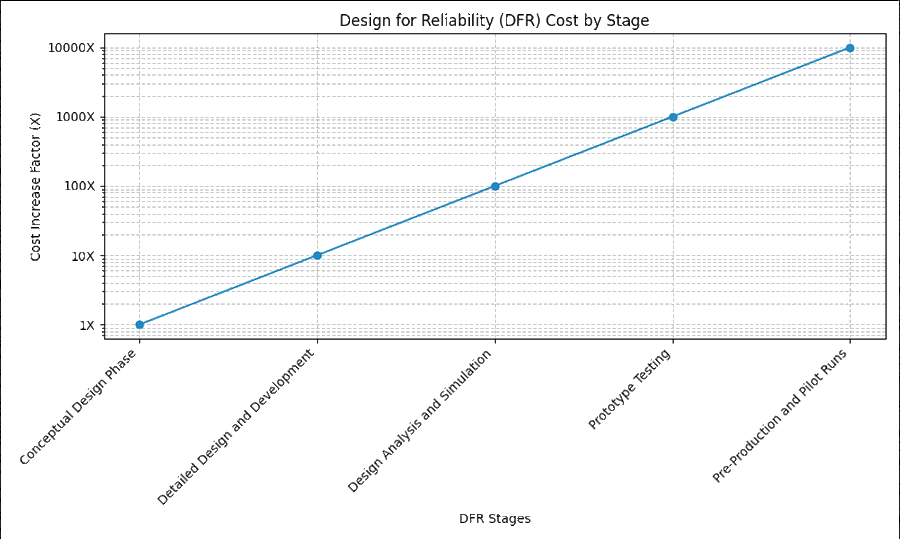

The most effective time to implement DfR is at the earliest stages of product development. This is because changes made during the design phase are generally less costly and less time-consuming than those made during later stages, such as during prototyping or after product release. Early implementation of DfR can lead to a more robust design, which can mitigate risks from defects and satisfy customer reliability expectations.

Key Stages for DfR Integration

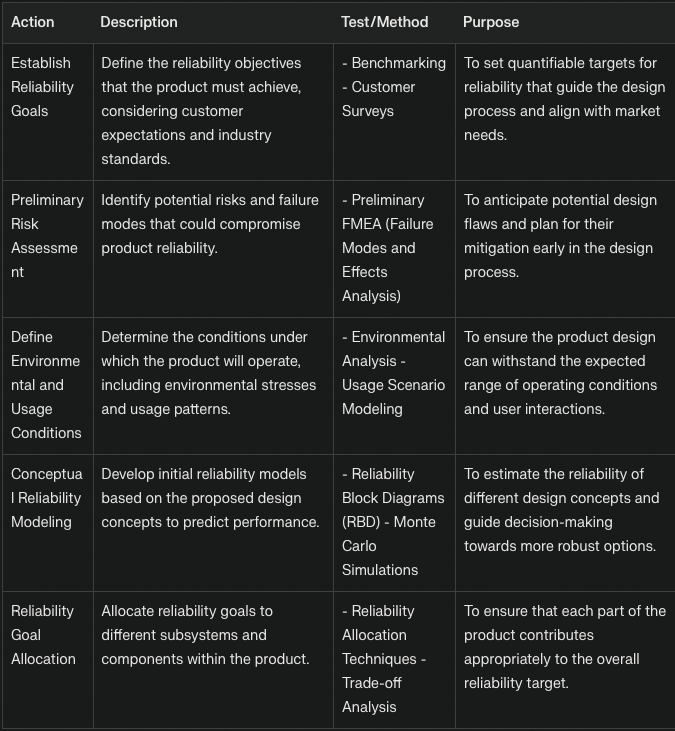

1. Conceptual Design Phase:

During the initial conceptual design phase, DfR principles should be applied to set reliability goals and objectives. This is when the foundational design decisions are made, and reliability targets should be established based on customer expectations and market requirements.

2. Detailed Design and Development:

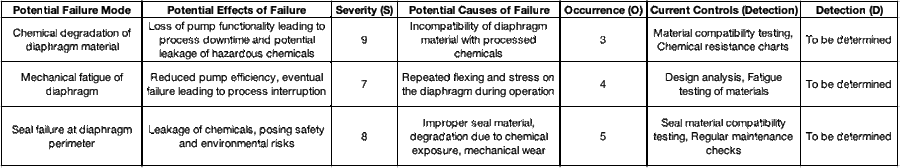

As the product design is detailed and developed, DfR tools such as Failure Modes and Effects Analysis (FMEA) and Fault Tree Analysis (FTA) should be used to identify potential failure mechanisms. These tools help in understanding how different design choices can impact the product’s reliability.

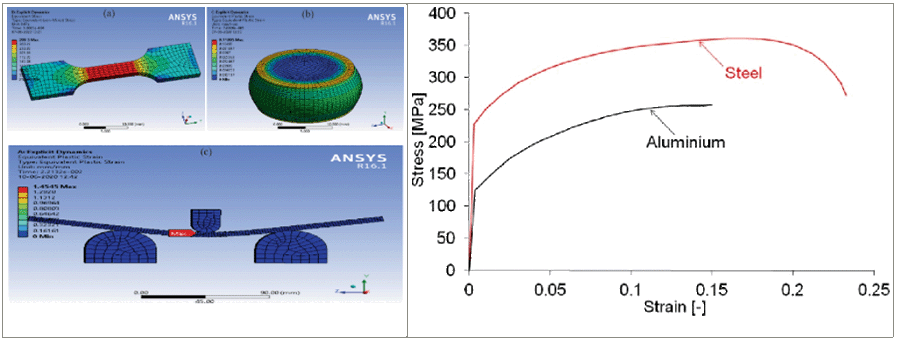

3. Design Analysis and Simulation:

Simulation methods and computer-aided engineering tools are used to predict and analyze potential failure modes. This includes stress simulations, thermal analysis, and other predictive modeling techniques that can highlight reliability concerns before physical prototypes are built.

4. Prototype Testing:

Although not the initial stage for DfR, prototype testing is still a critical phase where DfR principles are applied. Testing should be designed to validate the reliability predictions made during the design analysis phase and to uncover any unforeseen issues.

Accelerated Life Testing (ALT) is a key methodology used during prototype testing to simulate the operational conditions and stressors that the 3-way piston valve will encounter throughout its lifecycle, but in a condensed time frame. This approach helps in identifying potential failure modes and validating the design’s reliability more quickly than real-time aging tests.

Seal Integrity Test:

Description: Since seals are critical for preventing leaks in a 3-way piston valve, subject the seals to higher pressures and temperatures than expected in normal operation.

Purpose: Validate the seal material choice and design under accelerated conditions to ensure long-term integrity.

Material Compatibility Test:

Description: Expose the valve materials to the fluids (water, oils) at elevated temperatures and pressures.

Purpose: Ensure that the materials do not degrade or react chemically with the fluids, which could compromise the valve’s functionality.

Mechanical Wear and Fatigue Test:

Description: Cycle the valve through its open/close operations at an accelerated rate to simulate years of operation within a short period.

Purpose: Identify any mechanical wear or fatigue issues that could lead to failure, allowing for design improvements.

5. Pre-Production and Pilot Runs:

Before full-scale production begins, DfR should be revisited to ensure that the manufacturing process itself does not introduce reliability issues. This may involve additional testing and analysis of pre-production units.

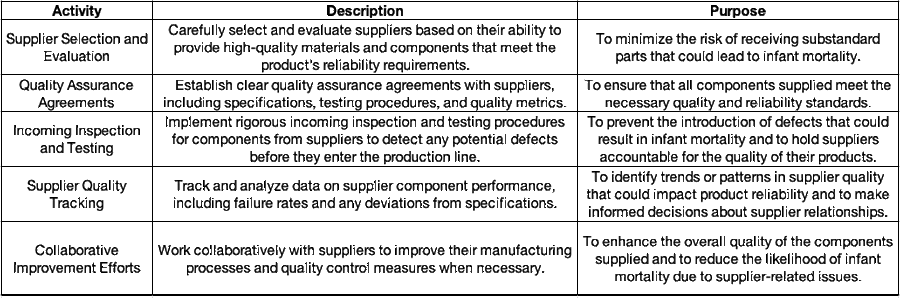

Supplier quality is a significant factor in the reliability of electromechanical products, particularly in the context of infant mortality, which refers to early-life failures that occur shortly after a product is put into service.

DfR Techniques and Considerations

Component Selection: Choosing the right components, such as selecting industrial or military-grade parts for harsh environments, is a fundamental DfR practice that affects the reliability of the final product.

EMI Mitigation: For electromechanical systems, special attention should be paid to electromagnetic interference (EMI) mitigation to prevent performance issues in electrically noisy environments.

Thermal Management: Effective thermal management is crucial for maintaining reliability, especially in designs that include components like microcontrollers and power MOSFETs that generate significant heat.

Concurrent Engineering: DfR requires the integration of product design and process planning into a cohesive activity known as concurrent engineering. This approach ensures that reliability considerations are woven into every aspect of the design and development process.

Conclusion:

In summary, the best time to have DfR during electromechanical product development is as early as possible, starting from the conceptual design phase and continuing throughout the detailed design, development, and pre-production stages. By integrating DfR early and throughout the product development lifecycle, companies can improve the reliability of their products, reduce costs associated with late-stage changes, and ultimately enhance customer satisfaction.

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.

Leave a Reply