Guest Post by James Kline (first posted on CERM ® RISK INSIGHTS – reposted here with permission)

Recently the International Organization for Standardization (ISO) released the 2021 certification numbers. Oxebridge Quality Resources did a good analysis of the 9001 numbers. This piece looks at the results from all the certifications and provides comparison in key certifications between China and the United States.

Overview

In October 2021 I discussed the results of the 2020 certifications numbers. (1) Until last year, ISO certification numbers for the dominate certification 9001 were on a downward trend. In 2020 the number of 9001 certifications increased. The increase was due to two primary factors. One was organizations which had not previously reported certifications reported them. The second was the growth in Chinese certifications.

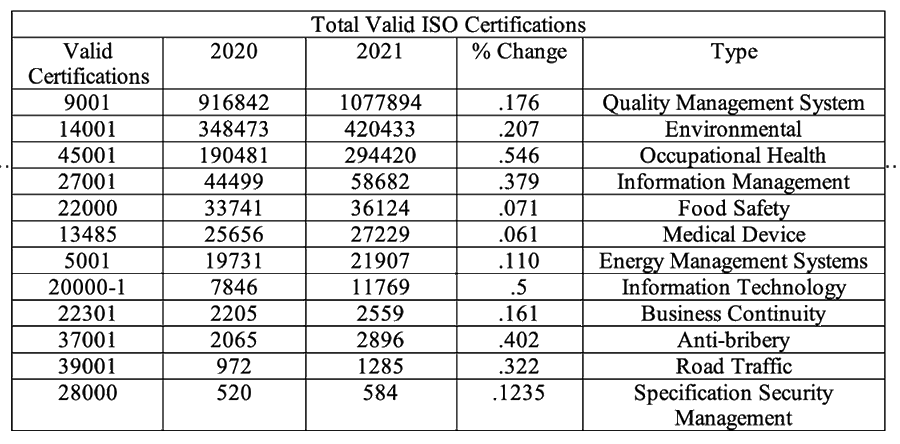

While I have concerns about the accuracy of the ISO certification numbers, they are the numbers available. Table 1 below shows the certifications by type for 2020 and 2021. (For any who are interested, in an October 2022 op ed for Oxbridge Quality Resources, I discuss additional concerns about the viability of ISO 9001.)

Certifications

What becomes obvious from a quick scan of the numbers is that 9001 dominates the total valid certifications. In fact, the five certifications below 9001 only total 836,888. That is 241,000 certifications less than 9001’s. The Environmental certification 14001, which is second in the number of certifications has 65,7461 fewer certifications than 9001.

The four top growing certifications over this period were: 45001 Occupational Health (.546), 20000-1 Information Technology (.5), 37001 Anti-Bribery (.402), 27001 Information Management (.379). The point is that even if 9001 certifications become less valuable, none of the other certifications even with higher growth rates, given their base numbers, can replace its importance any time soon.

Competitive Comparison

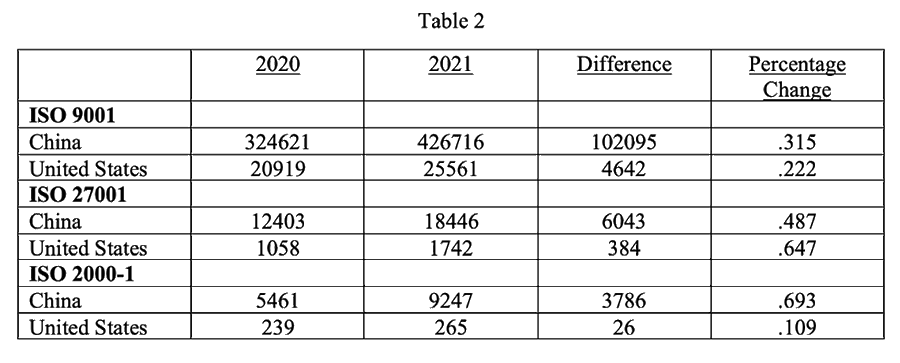

Having presented the overall numbers, let’s compare certification growth. Since many consider China to be the United States greatest adversary both militarily and economically, Table 2 compares the growth of United States and Chinese 9001 Quality Management Systems, 20000-1 Information Technology and 27001 Information Management certifications. These three are chosen for two reasons. First, ISO 9001 is the dominant certification and provides a competitive advantage to manufacturers. Second, information technology is a key component to Industry 4.0, the future manufacturing model. Thus, the numbers provide an insight into future manufacturing competitiveness.

As can be seen, China dwarfs the United States in the number of ISO 9001 certifications. It also has a higher growth rate from 2020 to 2021.

With respect to Information Management (27001) and Information Technology (20000-1) the Chinese are way ahead in both areas. While the United States had a higher growth in ISO 27001, the base is substantive lower. Thus, even with a higher growth rate, it will take some time to match the Chinese certifications. In the certification field of ISO 2000-1 Information Technology, except for the lower growth rate, the status of the United States is similar.

Conclusion

The ISO 2021 valid certification figures show a continued growth in certifications. ISO 9001 is the dominate certification. Thus, any change that ISO makes to this certification will have a substantive impact on the quality profession.

A comparison of the two dominate economies, the United States and China, shows the United States lags China in key manufacturing certification areas; ISO 9001 Quality Management Systems, ISO 27000-1 Information Management, and ISO 20000-1 Information Technology. The former can be seen as a proxy for the current manufacturing powers of the two countries. The latter two can be seen a proxies for the future manufacturing capabilities in the Industry 4.0 age.

Given the emphasis on information management, the latter two may become more important and provide greater competitive advantage in a manufacturing environment dominated by networking systems and artificial intelligence. Investors and the public may want to know whether the information systems are well maintained, and data is secure, before they invest in the company.

The data also provides some general policy guides. As noted in a prior piece (2) the United States federal government is pushing cybersecurity risk management, ERM, and enhance network infrastructure capability through Executive Orders, NIST guidelines and the Infrastructure Act. When combined with the general push toward Industry 4.0, Quality Management Systems will become more integrated into the computer network and the risk of a poor-quality product will become just another risk the organization must deal with.

In such a circumstance, the competitive advantage of having an ISO 9001 certification diminishes. The value of the certification and the need for external auditors will be further lessened if ISO expands 9001 beyond the current Risk Based Thinking, into ERM. In which case the need for external quality auditors will be almost nil. This is because internal auditors or staff from the big accounting firms will likely do the job.

Finally, the growth of Industry 4.0 and the need to ensure customers and investors that data is secure and well managed, may mean that having ISO 27000-1 Information Management and 20000-1 Information Technology certifications provide a greater competitive advantage than ISO 9001.

Endnotes

- Kline, James J., 2021, ISO Certification 2020 Survey Results, CERM Insights #253, October 31, 2021.

- Kline, James J., 2022, Cybersecurity and Enterprise Risk Management, CERM Insights # 393, October 17, 2022.

James J. Kline has a PhD from Portland State University. He has worked for federal, state, and local government. He has consulted on economic, quality and workforce development issues. He has authored numerous articles on quality and risk management. His book “Enterprise Risk Management in Government: Implementing ISO 31000:2018” is available on Amazon. He edited “Quality Disrupted” which is also available on Amazon. He can be contacted on LinkedIn or jamesjk1236@outlook.com

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.

Leave a Reply