In a previous article, we covered value stream concepts and characterized the value stream in the context of supply chain major sub-processes. We covered some important key performance indicators related to order fulfillment.

This article will look at work-in-process (WIP) and inventory using the Supply Chain Operations Reference (SCOR) model.

The SCOR model can be leveraged to assess and improve supply chains / value streams, directly leading to improved operational performance.

Recall that the SCOR model describes the business activities associated with all phases involved with satisfying a customer’s demand. SCOR is the only comprehensive, universally accepted and open-access supply chain standard. It has been used by thousands of public and private organizations around the world to assess and improve their supply chains, directly leading to improved operational performance.

Let’s go into the SCOR framework FOUND HERE and see what it reveals about WIP and inventory. In SCOR, WIP and Inventory is represented by keywords “inventory”, “product” and (non-fixed) assets. One can search on the keywords to get a sense of how the model accounts for WIP and inventory.

Of course, the supplier product, as well as the product made (or transformed) comprises the WIP and/or inventory (ie. keyword search the word “product” in the process model). I more detailed and customized value stream map would identify WIP and inventory locations in your specific process.

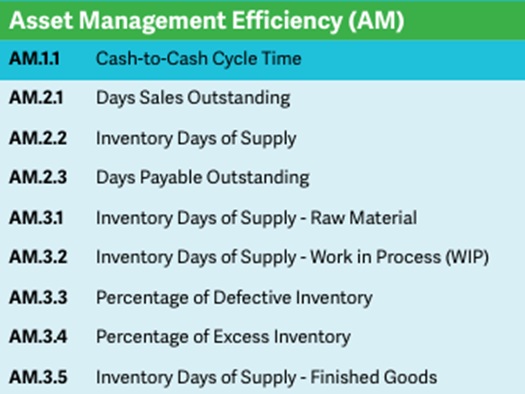

Inventory is emphasized in the metrics under Asset Management as follows:

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.

Leave a Reply