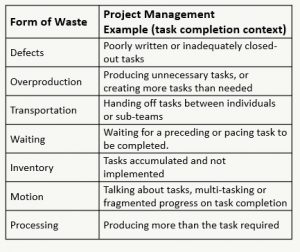

Our previous article identified several forms of waste, specific to completing tasks, as detailed by the following table:

Keep in mind, by focusing on tasks, this table assumes several things:

- a project selection process that ensures the project is valuable

- robust project requirements & planning

- project sponsorship and resources (team members) are made available

Without the above key characteristics in place, it’s possible to have a non-value-added project (regardless of efficient of task management).

Also, the limited scope of this article will focus on task execution in the absence of an integrated project schedule. (A Kaizen to-do list or action item list is therefore applicable here.)

Based on our knowledge of the above forms of waste, here are some attributes of lean task management and team meetings:

- Ensure tasks are clearly written in a way that the entire team (and new team members) can understand. Rewrite a task for clarity if necessary

- Leave the task open if not 100% complete (…per the teams mutual understanding of what it means to be completely done)

- Ensure team members who have been assigned tasks are also present in team meetings (…take attendance if necessary)

- Work toward quick and efficient team meetings…generally, we want team members to attend meetings having closed-out actions

- ‘Quickly’ escalate tasks that are late (the team leader can partner with team member, and sponsor, to focus additional attention on getting the task completed). Emphasis on “partnering”

- Minimize hand-offs of tasks to other actionees

- Identify preceding tasks, document them and ensure they become the ‘new’ focus. Avoid discussing tasks that can’t be started until a preceding task is done

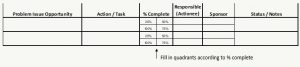

- Indicate task progress with a visual control (i.e. % complete or other visual indication showing progress)

Note 1: In case there is disagreement about the task, it may be helpful to document the reason (problem/issue/opportunity) in the preceding column on your task tracking sheet. The team may need to agree/refer to the stated reason for the action/task to ensure clarity of exactly what needs to be done.

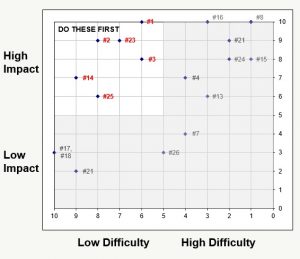

Note 2: Tasks can be prioritized by impact/difficulty. Note that the “Impact” ranking (scale of 1 – 10) can be tied to the problem/issue/opportunity: “how big is the problem?”….and the effort tied to the action (“what is the scope of the action” to address the problem).

Your team may have a different method of prioritizing actions, however, focusing on the highest impact, least difficult tasks can enable the team to get some traction and momentum toward their desired future state.

Everyone has their own task management style…also, there are many on-line task tracking tools available. Regardless, it is hoped this article helps give the reader some useful information to minimize waste in the process of executing tasks.

Leave a Reply