The boiler is the heart of a refinery or power plant. Boiler failures cause forced shutdowns and put the health of the plant at risk.

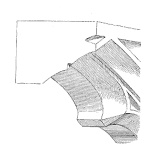

Some boiler designs run the risk of thermal fatigue failure. During service, the internal waterside surfaces of the tubes form a thin, protective oxide layer. Yet if the strains caused by the combination of (1) thermal expansion and (2) restraint during temperature fluctuations exceed the oxide strain capacity, the oxide cracks. Each thermal cycle will repeatedly crack the oxide, expose fresh metal when then oxidizes, eventually forming a crack. Technically this mode of cracking is corrosion fatigue-driven by thermal cycling. Yet since the boiler water will always be mildly corrosive, for boiler applications this mode of cracking is simply called “thermal fatigue”.

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.