The Impact of Precision Installation & Maintenance

Over the last several years I have been working on and off with customers to among other things build a maintenance strategy for their equipment that will insure the designed reliability of their assets.

A while back I was asked by one of these customers to come in perform several RCM (Reliability Centered Maintenance) analyses on some new equipment that was struggling to deliver the expected/promised production rates. As the team worked its way through the process of identifying failure modes I continued to ask the following questions:

- Do you know if the installers used precision alignment tools when they installed this?

- Do you know if the installers had a tension specification for the belts?

- Did the installers use torque wrenches when they installed this part of the machine?

- Did anyone notice if the installers used a laser transit and benchmarked the location and elevation of the machines?

- Can you tell me if the flange connections at this location were torqued at installation and retorqued an hour or so after start up?

- What grade bolts were used on the machine frame?

- What was the temperature in the room when the equipment was installed?

- What is the temperature in the room under normal operating conditions?

- Has anyone made any attempt to determine if the machine has moved at all?

It only takes a day of these types of questions before someone speaks up and asks; “Do you think they might have messed this machine up when they installed it?”

Well, I asked a lot of questions regarding precision installation techniques and based on the answers to those questions the contractor who installed your equipment didn’t use precision alignment techniques, didn’t use torque wrenches or follow a torque standard. They didn’t set a baseline for the location of your machines, and didn’t take thermal expansion and contraction into consideration when they installed it. Let me ask you, do you think any of the things I mentioned might impact the reliability of your new equipment?

Don’t answer… Think about this. How long would your car last if the company who made it decided that their people were so good they didn’t need to balance or align the tires or torque any of the screws, nuts and bolts used to assemble the drive train?

Would you get a month out of it before something failed and the car broke down?

Think about this the average person drives their car less than an hour a day and we want this equipment to run 24 hours a day, 7 days a week for several days at a time only shutting it down for an hour or so once or twice a week for product change.

In 1 day, the machine we are working on runs more than your car does in a month. A month of operation would be close to six months for your car. You have now been trying to run this equipment that was slapped together like Lego’s for over 6 months and now we are wondering why it’s starting to come apart and fail.

Should we really be surprised now that the equipment is struggling?

Now add 15 people who all have a different idea as to what our problem is. Fred thinks we are trying to run to fast. Bob thinks we are running to slow. Jim thinks this all has to do with the brand of motor the manufacturer used and they all have their hands on the machine making changes.

What you’re experiencing are the effects of not using precision installation/maintenance techniques at the time the machine was installed.

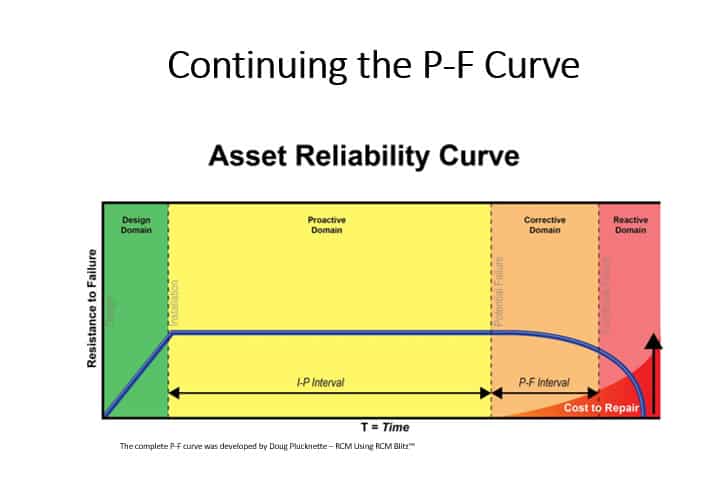

The room is quiet as the team digests this information I show them the following slide that has been part of my RCM Blitz™ facilitator training class since 2003.

This slide is one I put together several years ago, it illustrates the lifecycle of an asset and the potential impact of not doing the right things at the right time.

Starting from the left and working right we have the Design Domain. The useful life of an asset and its inherent reliability are determined when we design it. There are all kinds of tools available to help us to develop a reliable piece of equipment. The following list is not complete but is an example of the things we should do in the design phase:

- FMEA: Failure Modes and Effects Analysis

- RCM Blitz®: Reliability Centered Maintenance

- Design Standards

- Requirements Documents

- Select Supplier Agreements

- Reliability Block Diagrams

- Maintenance/Reliability Foundational Elements (Equipment Hierarchy, Criticality Analysis, Bill of Materials)

Moving to the right we have Point I, this is where we install the equipment. At this time the people we have install the equipment either ensure the reliability of the design by using sound precision maintenance/installation techniques or the ruin it by simply slapping the components together to build a machine. Precision Maintenance/Installation tools and techniques are life blood of your machine. The level of precision we specify and hopefully adhere to will have a direct impact on how long our equipment will run between required maintenance intervals as well as the useful life of the component. The following is a list of precision maintenance/installation techniques and is not all inclusive;

- RCM: Reliability Centered Maintenance can be done before or after design

- Precision Alignment and Balancing

- Torque Specifications

- Installation Standards and Job Plans

- PdM Tools at commissioning

- Precision Tools

- QA/QC Inspections at installation

Moving right from Point I we have the Proactive Domain, this is where the company who is operating the asset makes their money. The longer they stay in the proactive domain, the more money they make. So as we design and install our assets we should be always looking for ways to increase the I-P Interval. It’s in this proactive domain that we MUST apply PM (Preventive Maintenance), PdM (Predictive Maintenance/Condition Based Maintenance) Operator Care Tasks, Lubrication Tasks and Failure Finding Tasks. These routine maintenance tasks should be based on mitigating known failure modes for the components that make up your piece of equipment. Ignoring and or postponing these tasks will likely shorten the I-P interval. (Stop lubricating a bearing for example)

Continuing right we come to point P, known as Potential Failure this is the point where we first detect a failure has occurred by detecting a known failure condition. (Vibration, Heat, Noise, Increased Amperage, Change in Timing) The key to Point P is we should try to detect it as early as possible as this allows us the time to Plan, Schedule and Repair the item before secondary damage occurs.

As we move right from Point P we are now in the Corrective Domain of the Asset Reliability Curve. Our goal in this domain is to again identify Point P and repair the item before secondary damage occurs to other components. As an example, if we were monitoring the vibration of a bearing using vibration analysis and we detect that the bearing in now in the process of failing we should, plan and schedule to replace the bearing as soon as possible. If we wait the vibration will increase, the bearing will heat up and if left to its own devices the bearing will seize, the shaft will be ruined along with other components of the drive. This secondary damage drives the cost of maintenance and repair up and in many cases, increases the downtime as well.

Again moving right from Point P we come to Point F. Known as functional failure, this is the point at which the component or asset can no longer deliver its intended function. A pump for example might have a function that states it should be able to deliver 120 gallons per minute. If it’s delivering less than 120 gallons per minute, it is functionally failed.

The value of understanding Points P and F is both can and do move up and down the P-F curve depending on the technologies you may be using to detect specific failure conditions and how well you have defined functional failure. Remember in all cases your goal here should be to avoid secondary damage and minimize costs.

Moving right from Point F we have total failure. This is where the item has failed and the equipment will no longer run. Looking at the Asset Reliability Curve this area just before Point F and including total failure is known as the Reactive Domain. Believe it or not this is where a good share of maintenance organizations focus their efforts. Here is where the fire-fighting is done, where the overtime is earned and where our cost to do business is the highest.

The Reactive Domain is also the place where we once again ruin the Reliability and Useful Life of the new asset being installed. With the failure being “unexpected” we put new parts on order at a premium price and then pressure the people installing it to get the equipment running as soon as possible. At a time when we again should be paying close attention to the precision maintenance/installation standards we leave the tools in the drawer, slap it together and make it run.

In closing, the most important thing to remember is someone can design the best pump or machine in the world, if we don’t take the time to develop installation standards and ensure they are followed through on we can ruin that pump or machine before it even starts up. Quality, Reliability and Useful Life all depend how well we install and maintain our assets.

Doug Plucknette, Principal & World-Wide RCM Discipline Leader at Allied Reliability Group is a Reliability Engineering Consultant and Published Author of “Reliability Centered Maintenance using RCM Blitz™ and Clean, Green and Reliable. Having created the RCM Blitz™ Methodology he has been an RCM Practitioner and Trainer for over 20 years. Doug resides in Spencerport, NY and can be reached at plucknetted@alliedreliability.com

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.

That’s an Amazing literature!

I certainly am reading the best points of views when we talk about Reliability Subjects.

I also believe that the Probability of a machine to be successful starts by its installations.

As Reliability Engineers, our role is to pursue these kinds of Risks. Furthermore, Reliability Engineers’ eyes illustrate the occult profit for the employer, and treat the severity range in a milling as well as they can.

Best regards,

Thiago Lima

thiago0518@gmail.com

+5514996133216