Introduction

This is a rather depressing title for an article specifically on the topic of Reliability. After all, Reliability relates to the Probability of Success hence the contradiction.

However, the contradiction is not so much one as Reliability Analysis depends on having access to failure data. In other words, if the equipment does not fail, it might be difficult or even impossible to perform an analysis. Of course, we can source other types of data that are not failure records, but this is not the common approach.

And not only do we require failure data, but the more we have, the more precise the model. In other instances such as Accelerated Life Testing (ALT), we force components to fail in order to assess their reliability over time, work cycles etc. If the asset does not fail, it is sometimes difficult to get information on its future performance or durability. Hence the “pessimist” qualifier I use in the title.

The inference of missing failure records

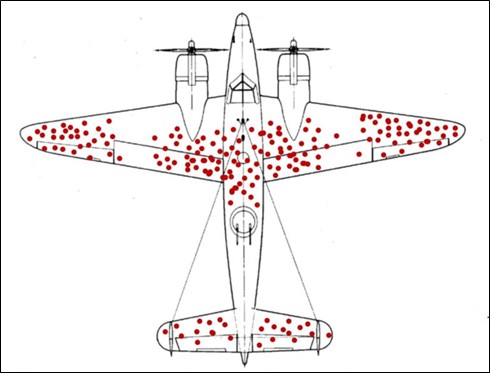

During World War II, statistician Abraham Wald worked on methods to minimize bomber losses to enemy fire. His team examined the damage done to aircraft that survived bombing missions and recommended adding armor to the areas that showed the least damage. The bullet holes in the returning aircraft (see Diagram 1 below) represented areas where a bomber could take damage and still fly well enough to return safely to base. Therefore, Wald proposed that the United States Navy reinforce areas where the returning aircraft were unscathed. Inferring that planes hit in those areas were the ones most likely to be lost. This concept is known as the Survivorship Bias.

In this case, we still need failure records but, in their absence, infer their characteristics.

But do we always need failure records to do Reliability calculations?

The answer is not always.

One can estimate Field Reliability Functions without life data. You don’t need to know each part’s time to failure. Larry George elaborates on this in his article “Estimate Reliability Functions Without Life Data”. He uses shipped and returned commodities as variables for the Reliability Functions. Using those variables, he demonstrates how population Field Reliability Functions can be estimated. George goes even further and uses these estimates to improve service and inventory management.

Another interesting aspect to the above process is being able to perform Reliability Analysis without necessarily investing in a Computer Maintenance Management System (CMMS). A CMMS can often be an unaffordable expense to some smaller companies.

Pessimism or Creativity?

Both Larry George and Abraham Wald illustrate the creative nature and mindset of Reliability Engineers. And the ability to think out of the box when it comes to solving a complex Reliability problem. The other aspect of creativity is defining a failure itself. It is actually the Reliability Engineer along with their peers that define the nature of a failure. The failure is not necessarily a total loss of function or catastrophic disintegration of an asset. It could be as simple as a signal indicating the start of deterioration. Such as a vibration spike in a pump detected through routine Vibration Analysis.

In this case, creativity actually overrides pessimism.

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.

Leave a Reply