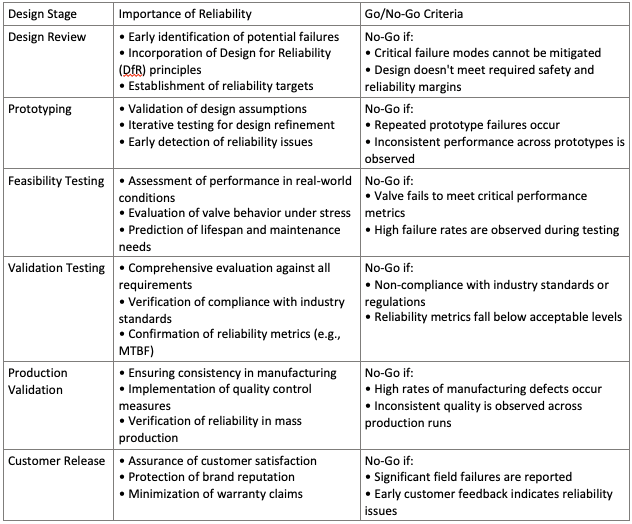

The Importance of Reliability in Product Development: A Case Study of an Electromechanical Valve for EV Battery Temperature Control. In the fast-evolving world of electric vehicles (EVs), the precision and reliability of components such as electromechanical valves are critical. These valves, which control the flow of coolant to manage battery temperature, must perform flawlessly under varying conditions. This article delves into the importance of reliability at each stage of product development, from design review to customer release, and highlights when a project might need to halt due to reliability concerns.

Design Review’s.

Importance of Reliability:

– Early Identification of Potential Failures: During the design review phase, reliability analysis helps identify potential failure modes and their impacts.

– Design for Reliability (DfR): Incorporating reliability principles ensures that the design can withstand operational stresses and environmental conditions.

No-Go Criteria:

– Unresolved Critical Failure Modes: If critical failure modes are identified and cannot be mitigated through design changes, the project should not proceed.

– Inadequate Design Margins: If the design does not meet the required safety and reliability margins, it must be revised.

Prototyping.

Importance of Reliability:

– Validation of Design Assumptions: Prototyping allows for the physical validation of design assumptions and reliability predictions.

– Iterative Testing: Reliability testing during prototyping helps refine the design and improve robustness.

No-Go Criteria:

– Repeated Prototype Failures: If prototypes consistently fail under expected operating conditions, it indicates fundamental design flaws.

– Inconsistent Performance: Variability in prototype performance suggests reliability issues that need addressing before moving forward.

Feasibility Testing.

Importance of Reliability:

– Operational Testing: Feasibility testing assesses the valve’s performance in real-world conditions, ensuring it meets reliability standards.

– Stress Testing: Evaluating how the valve performs under extreme conditions helps predict its lifespan and maintenance needs.

No-Go Criteria:

– Failure to Meet Performance Metrics: If the valve does not meet critical performance metrics such as flow control precision and response time, it should not advance.

– High Failure Rates: A high incidence of failures during feasibility testing indicates that the design is not yet reliable enough for further development.

Validation Testing.

Importance of Reliability:

– Comprehensive Evaluation: Validation testing involves extensive testing to ensure the valve meets all specified requirements and reliability standards.

– Regulatory Compliance: Ensuring the product complies with industry standards and regulations is crucial for market entry.

No-Go Criteria:

– Non-Compliance with Standards: If the valve fails to meet industry standards or regulatory requirements, it cannot proceed to production.

– Unacceptable Reliability Metrics: If reliability metrics such as Mean Time Between Failures (MTBF) are below acceptable levels, further design modifications are needed.

Production Validation.

Importance of Reliability:

– Consistency in Manufacturing: Production validation ensures that the manufacturing process consistently produces reliable valves.

– Quality Control: Implementing rigorous quality control measures helps maintain high reliability in mass production.

No-Go Criteria:

– Manufacturing Defects: High rates of defects during production validation indicate issues with the manufacturing process that must be resolved.

– Inconsistent Quality: Variability in product quality suggests that the production process is not yet stable or reliable.

Customer Release.

Importance of Reliability:

– Customer Satisfaction: Reliable products lead to higher customer satisfaction and reduced warranty claims.

– Brand Reputation: A reliable product enhances the brand’s reputation and customer trust.

No-Go Criteria:

– Field Failures: If initial field tests reveal significant reliability issues, the product release should be delayed until these are resolved.

– Negative Customer Feedback: Early negative feedback regarding reliability can harm the product’s market success and should be addressed before full release.

Conclusion

Reliability is a cornerstone of successful product development, especially for critical components like electromechanical valves in EVs. By rigorously assessing and ensuring reliability at each stage, from design review to customer release, companies can deliver high-quality, dependable products that meet customer expectations and regulatory requirements. Understanding when to halt development due to reliability concerns is crucial for long-term success and brand reputation. By focusing on reliability throughout the product development lifecycle, companies can mitigate risks, enhance product performance, and ensure customer satisfaction. This approach not only leads to better products but also strengthens the company’s position in the competitive EV market.

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.

Leave a Reply