Find the fortune maintenance can make for your business. Unfortunately, maintenance people get praise when they repair breakdowns. This embeds and promotes a culture of equipment failure acceptance in a business. Maintenance must be used to prevent equipment failures, not fix them. If you want to start a culture of failure elimination in your business you have to start putting a money value on the breakdowns prevented by Maintenance. You have to start praising and recognising them for the breakdowns they didn’t let happen. Maintenance needs to be praised and glorified for the money it makes a company, not singled out for the money it spends.

Keywords: failure prevention, defect elimination, equipment breakdown

to organisations that can meet their needs. Without maintenance no money is made and no customers are kept. A business that uses machinery to make its product cannot survive without maintenance. You make a lot of money from your maintenance when you to do it well.

So how valuable is maintenance? You could make a good case that it’s more valuable to a business than the money made by its Production or Sales groups. There is no production and no business without. It prevents a company losing money. In addition, it prevents a company from paying out money on workers compensation due to safety failures and on environmental damages due to process leakages. Maintenance is very valuable to a business. Here is an example of what I mean.

These three newspaper headlines of major equipment incidents happened in a six week period in Western Australia.

“$30 Million Refinery Glitch Stalls Fuel Users” The failure of a flange on a key piece of processing equipment meant no gasoline was made in the state for 2 weeks.

“Liquefied Natural Gas Project Back On Track after Production Train Repairs” The event cost $300 million in lost profit.

“330 Hospital Patients Suffer Cold Winter Showers for Two Days” A steam boiler failed putting the hospital at increased risk of spreading infection to hundreds of its patients and visitors.

These breakdowns were so bad that they made it to the news sheets. In a short six week period these three failures cost business hundreds of millions of dollars and put life at risk. How many smaller failures happen that do not make the news? These real events indicate the huge financial and business consequences industry suffers from equipment failure incidents. The cost of an incident may be no more than inconveniencing 330 hospital patients, or it can be the cost of months of future profits. The total cost of breakdowns to businesses using equipment to make their product (gauging from those few large incidents that make the newspapers, out of the many that happen) must be astronomical.

If maintenance people measured how much money they saved a business, it would be counted in fortunes. If you want to show people how valuable maintenance is, start pointing out how much it saved the company from paying out. Count the equipment failures prevented each month because of maintenance and report it. If the failures had happened, the business would have lost small fortunes each time. Failures prevented by Maintenance are moneys in the bank for the business.

Put a Value on the Consequences Prevented by Maintenance

Maintenance needs to show the value they bring to the business. Operations can show you how much production is made in a month and Sales can show you how much business they sold each month. Maintenance ought to be showing how much money they retained for the business each month.

You can measure the value of maintenance to a business by measuring the value of the breakdowns saved. Without maintenance there would have been equipment failures. There would have been massive amounts of money lost due to forced stoppages.

Many people would say that measuring such a thing is pointless because the Maintenance group are ‘just doing their job’. They would say that Maintenance are meant to stop failures and should not be recognised specially. But aren’t the Operations group just doing their job when they make product to be sold? When they have a good month why single them out for praise? Sales too are just doing their job when they sell product to customers. Why are they recognised with awards and glory when someone makes good sales – they were just doing their job? Maintenance needs to do the same as the Production and Sales groups do, and start recording how much money they saved the business from losing each month.

From a purely financial perspective companies spend money on maintenance because it pays back better than using that money somewhere else. If companies could get more value from their money than putting it into maintenance, they would. This means expenditure on maintenance must earn more for a company that using that money elsewhere. When a company makes an investment the expected return would usually be better than ten percent a year. A company that puts money into maintenance implies that its money earns better in the business than investing it elsewhere. If an investment returns ten percent, money placed in the investment is ten times that value. Each dollar of annual interest requires placing $10 into an investment. Such an investment makes maintenance worth ten times more to a business than it spends on maintenance each year. A $10 Million annual maintenance budget is worth $100 Million dollars in a safe 10%-earning investment to the business.

The investment approach above is one way to value Maintenance, but it will not bring recognition and honour to Maintenance. It is an interesting thing to know, but it cannot be reported on each month. An important value that can be reported on each month is the money made for the company by the failure prevention effort of Maintenance, i.e. the number of breakdowns saved each month.

Every breakdown saved can be counted. If a machine were not lubricated would it last a month before a bearing failed and the operation stopped? A vee belt found during an inspection to be close to failure and replaced is a breakdown saved. A centrifugal pump found cavitating and the cause rectified before the seal failed and forced an outage is another save. Had the failures happened they would have taken company money to fix and that money would have left the business forever. Every production stoppage prevented is money brought into the business by Maintenance.

Valuing Breakdowns Saved by Maintenance

Identifying the value of breakdowns saved (and breakdowns missed) is done using the Defect and Failure True Costs method. The acronym of DAFT Costs is intentional because companies are daft (silly) to let breakdowns happen to their business. All breakdowns are preventable by using very simple methods. But businesses don’t do those basic things properly and they suffer breakdowns. Breakdowns are a company’s own fault and so that makes them silly and daft to let them happen.

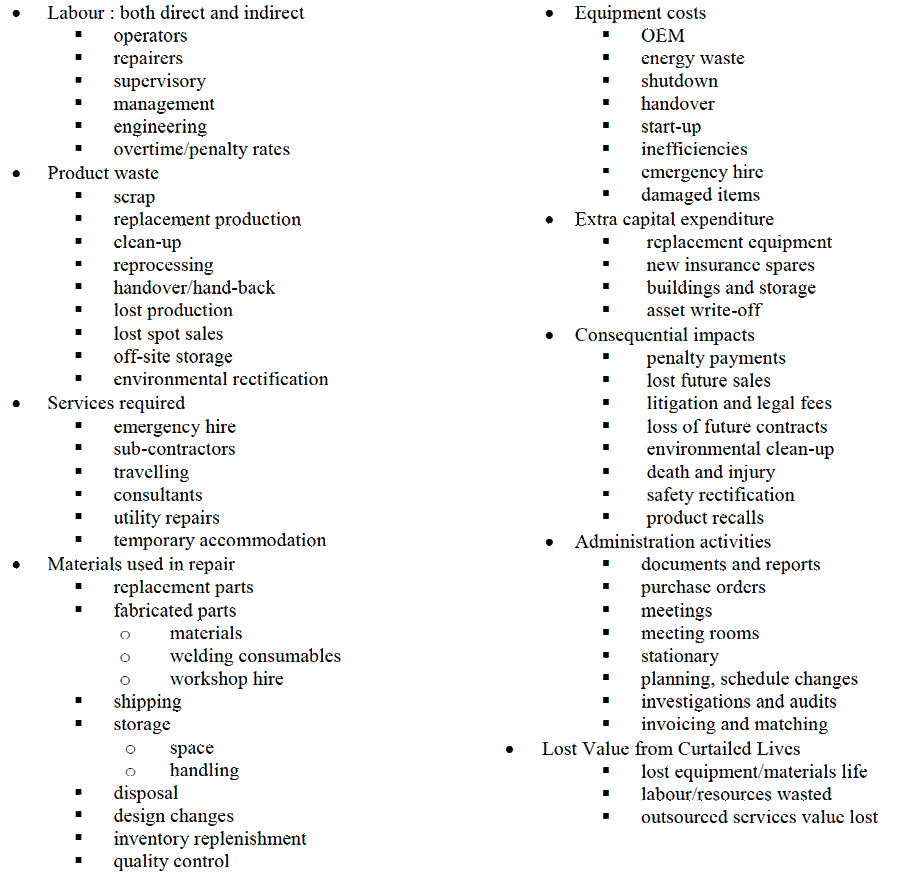

The DAFT Costing method values the business-wide impact of equipment failure. Breakdowns saved by Maintenance keep that money in the business. This money is what Maintenance made for the company. You calculate the DAFT Cost of breakdowns by using a spreadsheet to compile the value of all the costs in the table below that resulted from the breakdown. Had there been a breakdown those costs would have been paid by the business. But Maintenance ‘did their job’ and saved the money.

Show the Money Made by Maintenance in the Monthly Department Report

Maintenance can make money for a business, just like the Operations group and the Sales group ‘make money’. The money that Maintenance makes a business from DAFT Costs not spent can dwarf the money made by Production or Sales. Start reporting the real value maintenance brings to your business, and not only the cost. Maintenance needs to be praised and glorified for the money it makes a company, not singled out for the money it spends.

Claiming honour makes maintenance people uncomfortable. They are not the sort of persons that openly seek recognition for their work. But they love it when they get it!

Changing to Failure Prevention Paradigms

Unfortunately maintenance people usually get praise when they repair breakdowns. This is a certain way to promote the wrong message about equipment failures. Instead of promoting role models that prevent failure, it promotes role models that fix broken equipment. In this negative paradigm you first must have equipment stoppages, and then maintenance does its job. People come to think that it is okay to let equipment break and that spending money on fixing failures is acceptable.

Isn’t that a daft way to run a company – letting things break and then spending your profits to fix them! No wonder companies keep having equipment failures – they willingly accept failures and breakdowns and then praise people for them.

If you want to change paradigms to one that encourages failure prevention, start counting the number of breakdowns saved by Maintenance and start praising maintenance people for doing prevention and defect elimination. By counting the money Maintenance makes for the company you show people how important and valuable the maintenance effort is to improving and growing the business.

My advice to Maintenance Departments everywhere is the well-known phrase uttered by characters in the 1996 film ‘Jerry Maguire’ “Show Me the Money!” So set-up your DAFT Cost spreadsheets, and start counting the fortunes made in Maintenance.

My best regards to you,

Mike Sondalini

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.

Leave a Reply