Organizations often accumulate a list of desirable projects, however, may not have project management bandwidth to filter or manage them effectively.

While project management is a respected discipline, the Project Management Institute Body of Knowledge (PMBOK) has swollen to several hundred pages. This level of detail and complexity makes it difficult to absorb and apply for ‘informal’ project managers.

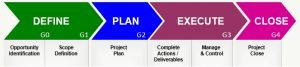

With this in mind, project management can be effectively taught and applied using the following (simplified) phases and review gates:

Let’s review these phases and gates and the corresponding review criteria:

Define

- What is the desired outcome?

- Is it a desirable project?

- Who are the team members and stakeholders?

- What is the project scope?

- What will the team do? (initial deliverables, high level actions)

Definition Gate 0 – review and approve the opportunity before further definition begins.

Definition Gate 1 – review and approve the project detailed definition & scope. Ensure the team members are aligned and committed to a successful project.

Plan

- How will the team perform the project?

- What will the team do? (detailed level including deliverables, actions, & milestones)

- How long will it take?

- What are the risks?

- How will the team communicate project status to stakeholders?

Planning Gate 2 – estimates of cost (resources), scope and schedule is understood and acceptable to proceed with the project. Ensure project execution will proceed based on a solid plan.

(Note: As evidenced by the above phases, a fundamentally solid plan is emphasized to ensure successful projects.)

Execute

- How are we executing vs. the plan?

- What are the changes?

- Is the team effectively communicating project status to stakeholders?

Execution Gate 3 – ensure project execution & implementation of deliverables/actions. Interim reviews should take place before the team’s final execution phase exit (gate) review.

Close

- Are we done?

- How did we do?

Project Close Gate 4 – ensure the project is complete and original objectives were achieved. (Gate 4 may be combined with the final Gate 3 review and approval.)

With the above questions we can see the critical thinking to ensure “who, what, how, when”, etc and to ensure good project quality. We’re also thinking in terms of the project management triple constraints (scope, resources and schedule). In the part 2 we’ll discuss some tools that enable this simplified project management process.

Leave a Reply