I have heard that “Reliability and Quality are kissing cousins” and also that “Reliability is Quality over time.” Neither of these definitions ring true to me. To be honest I’m a smidge offended because both of these terms diminish the value of the objective of reliability. I would state that reliability is “The design of a device or system so that it works as intended consistently over it’s defined use-life.” To me the key differentiator from my definition and the previous two descriptions of reliability is the word “design.”

Reliability is part of the design process. The majority of tools in the reliability tool kit are intended to aid the design process. The intent is to release a first generation product that demonstrates the characteristics of a completely mature design. Mature indicates that the design will not go through continuous updates throughout it’s life in the field that are necessitated because of poor reliability performance. Products that are not mature when first released have revision 1.2, 2.0, 2.5. Have you ever held off on purchasing a product because it was the first year the new technology was introduced? “I’ll wait a year or two until they have worked out the bugs.” I know that this is my motto for many technologies and products.

Reliability is part of the design process. The majority of tools in the reliability tool kit are intended to aid the design process. The intent is to release a first generation product that demonstrates the characteristics of a completely mature design. Mature indicates that the design will not go through continuous updates throughout it’s life in the field that are necessitated because of poor reliability performance. Products that are not mature when first released have revision 1.2, 2.0, 2.5. Have you ever held off on purchasing a product because it was the first year the new technology was introduced? “I’ll wait a year or two until they have worked out the bugs.” I know that this is my motto for many technologies and products.

So what is Quality then? Quality to me is the intent to manufacture a product to specifications. The tool box primarily is intended to measure and adjust parameters that affect irregularities between product units. If a product is designed in a manner where it is unlikely to handle the variabilities of it’s defined manufacturing specifications, use case or environment, improving quality can do nothing. A high quality product may be one that manufactures the inability to handle those three variabilities perfectly consistently. High Quality and low reliability is a consistency across a population to have the same sensitivities to manufacturing, use, and environment variabilities. A highly reliable low quality product is a process that has created a population that has individual units able to handle high variability and others that are very sensitive to variability within the same specified design.

So what is Quality then? Quality to me is the intent to manufacture a product to specifications. The tool box primarily is intended to measure and adjust parameters that affect irregularities between product units. If a product is designed in a manner where it is unlikely to handle the variabilities of it’s defined manufacturing specifications, use case or environment, improving quality can do nothing. A high quality product may be one that manufactures the inability to handle those three variabilities perfectly consistently. High Quality and low reliability is a consistency across a population to have the same sensitivities to manufacturing, use, and environment variabilities. A highly reliable low quality product is a process that has created a population that has individual units able to handle high variability and others that are very sensitive to variability within the same specified design.

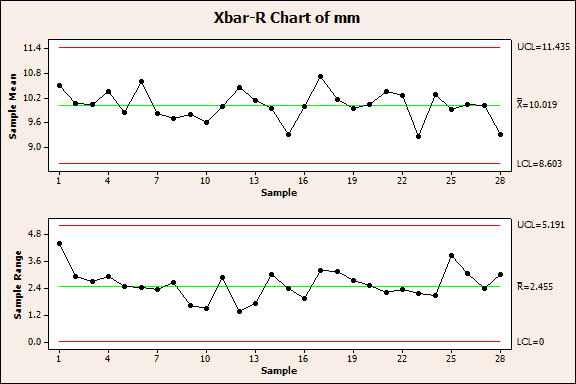

I’m not going to go so far as to say that reliability is pro-active and quality is re-active. Quality can be pro-active by putting systems in place to ensure that manufacturing variabilities are minimized. Cpk charts are an amazing tool that can identify trends that will lead to defects before they occur. The rumble strips on a road are the Cpk chart for driving. It provides an indicator that you are having a trend that is going to lead to an issue and a correction is advised.

So I believe that taking some time to think about and share perspectives on what both Reliability and Quality are can help organizations and teams better implement the tool they provide.

-Adam

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.

Leave a Reply