As a reliability guy I love seeing how stuff works. Was recently given an opportunity to mess around and compare a new product to it’s siblings in a field I love, welding. I recently provided some input on an article release by Superiorglove about types of insulation and heat conduction. Superiorglove is a glove manufacturer that makes about every type of glove you could imagine, many are really impressive industrial applications gloves. I like how much they get into the science of it. In our discussions I used an example of how my TIG welding gloves protect against conductive and radiative types of heat transfer. They informed me that they had a TIG welding glove line and would love if I would review four of their models. I happily accepted because I love to weld, check out how things work and …free gloves.

I was once told by a welding mentor “The single most important factor to creating a good TIG weld is being comfortable.” Seems odd when there are so many other factors and steps for good welding. But it is absolutely true. If you are not comfortable you can not have the precision in motion and handling that is required for TIG welding. In TIG you are controlling many factors at once. The final link in this comfort transfering to a beautiful weld is the glove. This is why TIG gloves are their own breed. Most important is how the glove transfers your input to the torch and the feedback the torch gives to your hand.

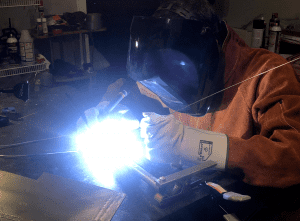

The challenge for a TIG glove manufacturer is “How do you make a glove that provides great feel but protects against a mini blazing sun two inches from your fingers?” A welding arc is at approx 11,000 degrees F and gives off enough UV light to give you a serious sunburn from three feet away in a single welding session. For example: I have a 2″ band of extremely tan skin on my right bicep. Earlier this year my leather welding sleeve slide down leaving a gap between my t-shirt sleeve and the welding sleeve.

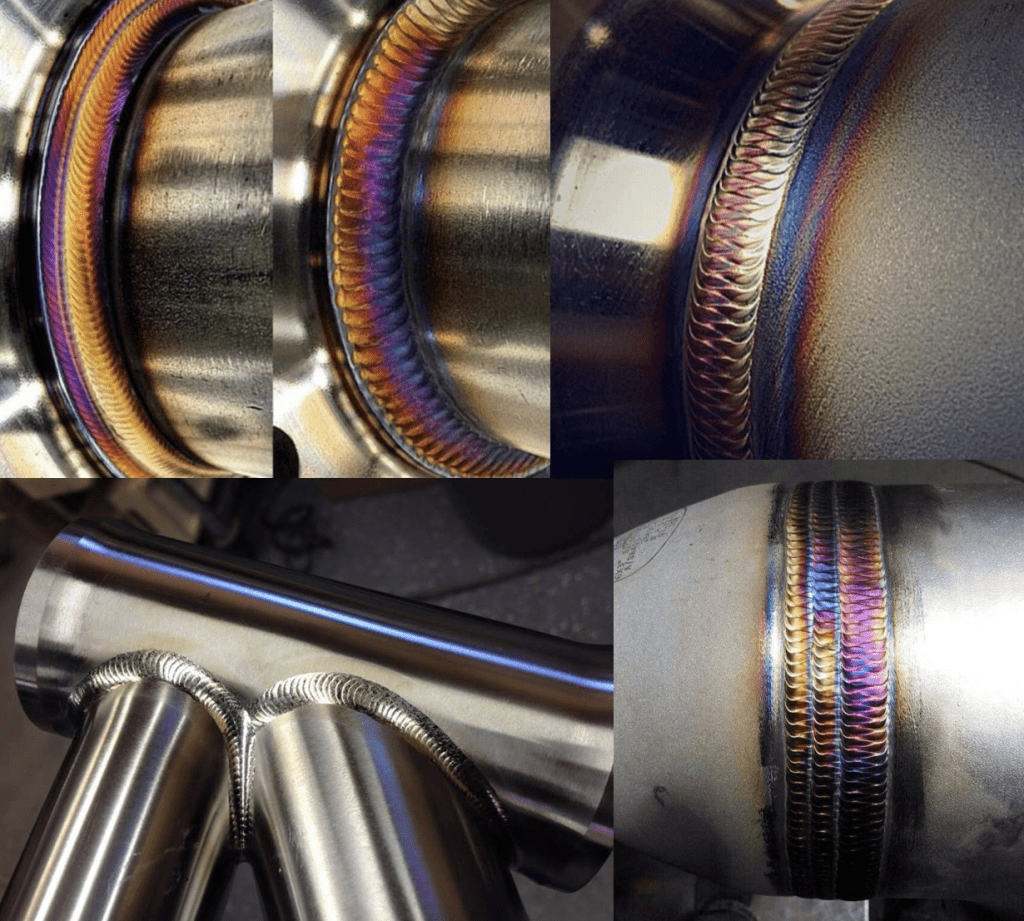

To get a sense of why feel and control are so important with TIG take, a look at these welds from some masters. Compared to MIG or Stick welding, TIG requires great finesse. These pictures are the work of some amazing pros, some have instagram accounts just to showcase their latest TIG stitch. To be clear none of this is my work.

The four Superiorglove Endura models I am reviewing in order of price point are Endura Goatskin, Endura Heavy Duty Horsehide, Endura Grain Pigskin, Endura Premium. The premium is approx 4X the cost of the entry level Goatskin. Each has a different product objective balance of durability, heat protection, comfort, features, and cost point.

- #1) I started with the Goatskin, an entry cost point glove. Was nice for an entry level glove. Stiffer than the higher cost point gloves but also thick enough to handle grabbing material and moving it around. So it will last even though a novice will be a bit rough with them. A problem with TIG gloves is they tend to be delicate which limits general use. A welder will spend a lot of time taking their gloves on and off to put on work gloves. If I was going to be welding large structural pieces and handling rough edges while working these would be a nice balance. They appear to be very puncture resistant for light gloves with a reasonable compromise in feel and flexibility.

- #2) The heavy duty horsehide are just that. Heavy Duty. These are for doing industrial work, handling heavy sharp objects while welding. The finesse

needed to make an artwork quality weld isn’t there but probably not needed in the situations you would grab them. If I was headed to a field to fix a broken tractor or just getting some I-beams joined these would be the gloves. In those situations my regular TIG gloves would get destroyed. I would be swapping them with heavy work glove constantly. So these would be a good all in one solution. An area for improvement in this model would be thickening up the side of the hand. I marked the area with black marker in the below picture where I would do this.. For a long and deep weld the workpiece is going to get very hot. I may be in a position where I need to support some of my weight with my torch hand. Thickening up this section would be a nice add with no further loss of dexterity.

needed to make an artwork quality weld isn’t there but probably not needed in the situations you would grab them. If I was headed to a field to fix a broken tractor or just getting some I-beams joined these would be the gloves. In those situations my regular TIG gloves would get destroyed. I would be swapping them with heavy work glove constantly. So these would be a good all in one solution. An area for improvement in this model would be thickening up the side of the hand. I marked the area with black marker in the below picture where I would do this.. For a long and deep weld the workpiece is going to get very hot. I may be in a position where I need to support some of my weight with my torch hand. Thickening up this section would be a nice add with no further loss of dexterity. - #3) The Pig skin Endura are like the TIG gloves I currently use. If you are skilled enough to want good tactile feel and torch control this is the type, construction, and material needed. Pigskin are

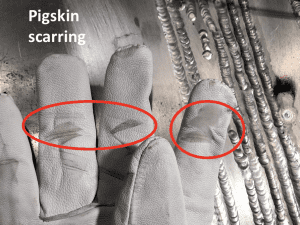

optimized for feel, flexibility and fine control. For non welders think of the thickness of ladies leather dress gloves or gentleman’s driving gloves. The compromise is of course thermal protection and durability. You are going to burn your hands if you pick up a hot work piece. They will rip eventually if you handle rough heavy material. So typically I grab these pigskin type when I am welding at my work bench with nicely machined pieces. I pick up hot material with a thick rag or pliers. I found these Enduras to be a nice selection for this type of high dexterity glove. I did find the heat damage they received when I tried handling hot material to be significant. The material got compressed and hard where it was burned, scarred. Some of this is expected with a super light glove. but I imagine a not so delicate worker like myself might go through these pretty quickly. So maybe more fr th epure artists. My index finger got hot fast due to radiative heat as well. Maybe these could be improved with a little bit of thickening at the radiative heat points. I marked where I would add protection in pink.

optimized for feel, flexibility and fine control. For non welders think of the thickness of ladies leather dress gloves or gentleman’s driving gloves. The compromise is of course thermal protection and durability. You are going to burn your hands if you pick up a hot work piece. They will rip eventually if you handle rough heavy material. So typically I grab these pigskin type when I am welding at my work bench with nicely machined pieces. I pick up hot material with a thick rag or pliers. I found these Enduras to be a nice selection for this type of high dexterity glove. I did find the heat damage they received when I tried handling hot material to be significant. The material got compressed and hard where it was burned, scarred. Some of this is expected with a super light glove. but I imagine a not so delicate worker like myself might go through these pretty quickly. So maybe more fr th epure artists. My index finger got hot fast due to radiative heat as well. Maybe these could be improved with a little bit of thickening at the radiative heat points. I marked where I would add protection in pink.

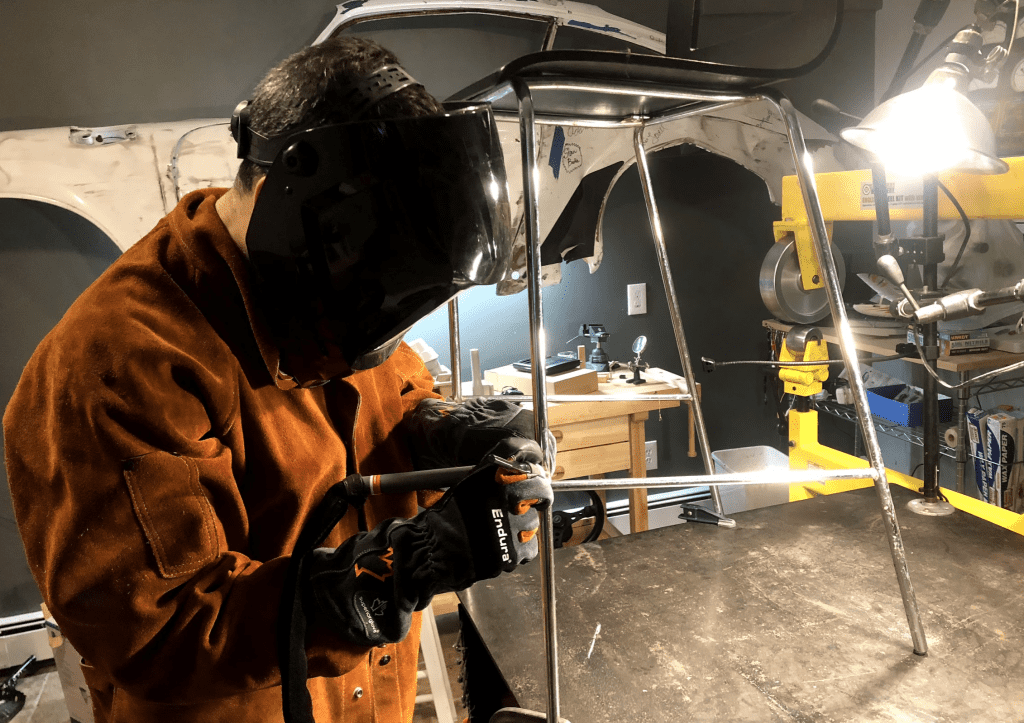

- #4) The Premium was really impressive. I haven’t welded with a glove like this before. A very impressive mix of flexibility, feel, heat control, and ruggedness. It is a great all around TIG glove that will likely be the first one I grab from now on. Great feel (not as sensitive as the pigskin) but really good and I can grab/rest on hot work pieces. It controlled radiative heat well on long stitches as well. I would call them the Porsche Panamera of gloves (yup I worked cars even into a glove review). It’s a 450hp station wagon with all wheel drive and great handling. You have all the boxes checked with a 90%. Yeah you could get a 911 Carrera Turbo sports car. It’s faster and handles a bit tighter. But it’s staying in the garage most days because the kids can’t fit in it and all winter it’s off limits because it’s just going to throw itself in the ditch. The Panamera is going to give some really great sports car speed and handling but you can also pick up the kids and impulse buy a table saw at Home Depot.

My two suggestions to make the Endura Premium even better.

1) I would add extra insulation to the bottom side of the hand (touches the work/table) and the pinky finger. This section of the hand often get’s ignored in TIG gloves and requires hand position adjustment to lower the temp at those locations. I have even wrapped my glove pinky finger with car exhaust insulation wrap (class/ceramic fiber cloth) to help with this with light gloves. There are times where I want to turn my hand in more for improved control but didn’t due to how hot my hand got. So I found myself reducing comfort which goes against the #1 rule.

2) There should be an option for a shorter glove collar. The gauntlet is nice if you are just doing quick work and have a flannel shirt on. But if you have a full welding jacket or leather sleeves then it’s redundant. It requires adjustment to get them over the heavy leather sleeves. Not a big issue but if I had the option I would have gotten a shorter collar because I don’t do work without leather sleeves or a jacket. I have burnt an elbow/forearm on hot work pieces enough times to find value in spending the extra 10 seconds to put on welding sleeves or jacket.

So I’ll be grabbing the Premium for the next few projects and continue to explore them. I am curious how they will last over time if I handle heavy rough and sharp pieces.

So from a guy who has made a career out of breaking stuff I enjoyed getting a chance to put some investigative thoughts on paper. It is also fun to see the product factor balance in the different models. “Pigskin” performance at all costs, “Horsehide” durability at all costs, “Premium” going for it all.

I think this was also a nice demonstration of how testing quickly generates design input. I don’t believe people really understand how reliability testing is an amazing contributor to the design process. I came up with three design improvements without even intentionally sitting down to do it. I always push my customers to do reliability testing with prototypes and continue in parallel through the entire design phase. They always make significant design improvements in the first product release that would have not been made until 2.o. If you leave reliability testing to the end of the program you may still see these design opportunities, but it’s too late to include in the current product release.

-Adam

P.S. The Premium actually look so cool and has such good feel and thermal protection that I’m sure I could use them as a second pair of racing gloves? I suggest Superiorglove investigate a racing suit fire rating and sell them in the car racing apparel market as well!

(I’m noticing I have a lot of protective fire gear for my hobbies, It’s a lifestyle)

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.

Leave a Reply