Error Proof Quick Mating Part Location And Alignment. For speedy and easy maintenance it is best to design equipment with a means to insure accurate and exact location of contacting parts. This removes the opportunity for alignment errors during rebuilds and speeds-up maintenance overhauls. In this article is a sketch of two common methods used to provide positive and certain location and alignment between mating parts.

Keywords: face to face location, shaft alignment, spigot connection, tongue & groove recess

Error-proofing refers to the implementation of fail-safe mechanisms to prevent people from producing defects. The philosophy behind error proofing is that it is not acceptable to make even a very small number of mistakes, and the only way to achieve this goal is to prevent them from happening in the first place. In essence, error-proofing becomes a method where mistakes are stopped at their source rather than down the line, after additional value has been added (and then wasted). Achieving extremely high levels of plant and equipment reliability requires this type of focus on prevention rather than detection and later correction.

To reduce repair time and insure accurate rebuilding it is best to ensure mating parts can only be installed one way. It is a simple matter to design grooves, recesses, spigots or dowels into equipment designs that insure the rebuild will always be accurate and correct.

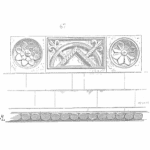

Two common methods to align mating parts is to use a spigot that fits exactly into a recess or a ‘tongue’ that fits exactly into a groove. When the two parts are put together they can only be assembled in one way. After assembly they are automatically within design alignment tolerance.

Tolerancing is critical when using recesses, grooves or dowels. The tolerances for the locating devices must ensure the required alignment and squareness tolerance between parts are still within the required accuracy.

These alignment methods are easily understood by operators and maintainers and no special knowledge is required for their successful use.

Disclaimer: Because the authors, publisher and resellers do not know the context in which the information presented in this article is to be used they accept no responsibility for the consequences of using the information contained or implied in any articles.

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.

Leave a Reply