Roll mills, drum dryers, kilns, ball mills and rotating reactors usually turn on metal tyres and trunnion rollers.

Eventually, the tyres and rollers wear out or fatigue and require repair or replacement.

Usually, the equipment manufacturers keep material specifications as proprietary information and one is forced to buy the parts from them.

In situations where supply from the original manufacturer is impractical- you will be forced to find alternate materials and suppliers.

They will require a materials specification from you to fabricate or cast a replacement.

Wear mechanism

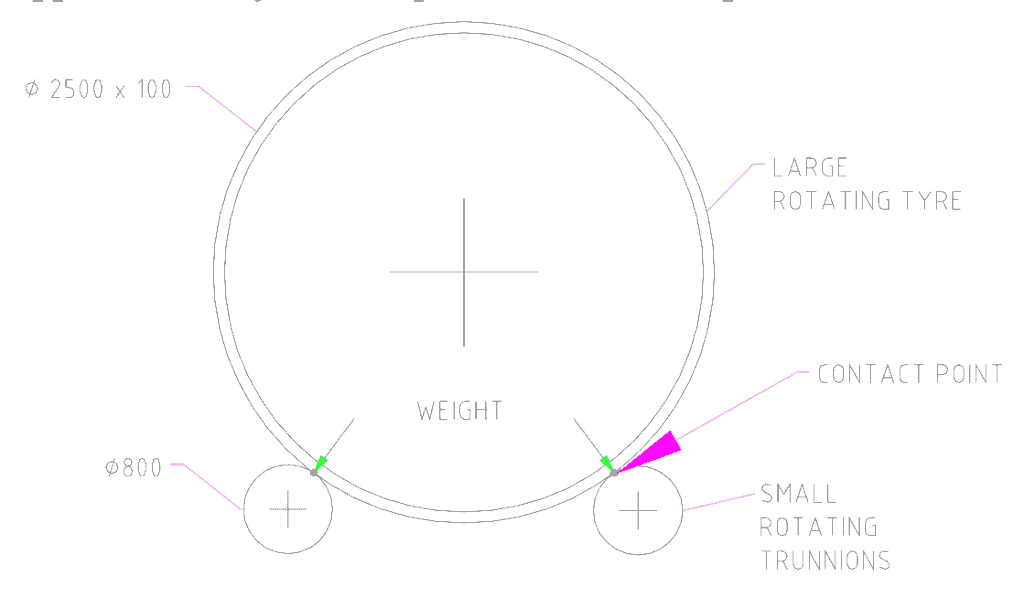

When properly aligned the rollers carry the weight of the drum and product on a very narrow contact line formed between the tyre and roller (FEED FORWARD Volume 1 No 5).

The sketch below shows the location of the thin contact line formed between tyre and roller.

The stress created on the contact line fluctuates as the drum rotates and the contents move. This high, fluctuating stress causes work hardening of the roller and tyre surfaces.

Examples

Tyres on a twin tyre, 2-meter diameter, rotating drum dryer of three tonne operating weight had to be replaced after several years of service revolving at 6 RPM.

The rollers were 150mm wide and 500mm diameter turning at about 24 RPM. The tyres were repaired in-situ as they could not be removed. They were re-skinned by welding two rolled half rings of boilerplate to the remnants of the old tyre. (Make the mating ends at 45 degrees to the axis so the hard weld rolls over each roller in point contact and do not cause an abrupt impact as would occur if the weld was made axially.)

Some months after repair it was noticed that the tyres were wearing faster than expected.

Upon investigation, it was found that the trunnion rollers were made of 4140 steel and had a surface hardness of 320HB while the fabricated boilerplate tyres had a surface hardness of less than 250HB.

Contrast this to a 3-meter diameter rotary reactor of 35 tonne operating weight rotating at one-third revolution per minute mounted on trunnion rollers of 800 mm diameter.

The 200 mm wide rollers turned at 2 RPM. The tyres were made of Bisalloy 80 with a rolling surface hardness 310 HB while the 4140 steel rollers were 360 HB. However in this case, after two years in operation, there was no evident wear.

On review, it appeared that the wear rate for rotating metal tyres and trunnions was influenced by the surface hardness, the disparity between surface hardness and surface velocity.

Specifying steels for rolling surfaces

Fortunately, the choice of steels to use in making tyres and rollers is very similar to the steels used to make railway lines and locomotive tyres.

These are made from carbon steels with a carbon content about the 0.5% to 0.8% and initial surface hardness of about 280 HB to 320 HB. The surface hardness increases with usage.

Peter Laczko of Peter Laczko Pty Ltd (ph 61 8 9370 5343) offers this advice on selecting material for rollers – “The rollers are best in a pearlitic steel at about 320 to 360 HB hardness.

This can be achieved by casting 1050 carbon steel oil quenched and tempered, or by casting in AS 2074 L2B high carbon chrome steel normalized and tempered. If forged steel is used then 1050 carbon steel can be used as above, or 4150 normalized and tempered can be used.

If castings are used they must not be welded on the running surface at any stage because uneven wear results in the weld and HAZ (heat affected zone) leaving marks in the tyre and rough rotation of the kiln.”

Contact a metallurgist

In situations where the material composition is unknown, you may need help from a metallurgist.

Most of the steel supply companies have access to a metallurgist who can advise you or else contact an independent metallurgist. The details they will require of the equipment concerned are its function, duty, and conditions in which it operates.

Surface lubrication

To help minimize tyre and trunnion wear, dry lubricant blocks rubbing against the tyre can be used. These are available from specialist lubrication companies.

Mike Sondalini – Maintenance Engineer

DISCLAIMER: Because the authors, publisher, and resellers do not know the context in which the information presented in the articles is to be used, they accept no responsibility for the consequences of using the information.

If you found this interesting, you may like the ebook Bulk Materials Handling Introduction.

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.

Leave a Reply