Thermal Growth with Daus Studenberg

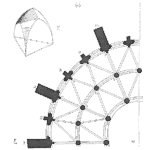

When a machine heats up and starts expanding in all the directions is simply called the thermal growth. When it actually comes to understanding it, it means that you are dealing with machinery movement and that can cause misalignment in the machine. Also, your alignment is only as good as your target. If your machine starts moving and you have a bearable misalignment in the off-set condition, you will allow that bear minimum of misalignment in your machine deliberately in that condition. So, before you detect thermal growth, you need to have a correct target in place to measure it against.

In this episode, we focus on the following points:

- What is thermal growth?

- What are the standards of thermal growth measurement?

- What packages are available that come with laser alignment tools?

And much more!

How many times has an asset been installed or commissioned, only to have it fail in a few days or months when it should have lasted even longer? If you look at the study by Nowlan & Heap, they have found that only 11% of

How many times has an asset been installed or commissioned, only to have it fail in a few days or months when it should have lasted even longer? If you look at the study by Nowlan & Heap, they have found that only 11% of  A major asset is being installed, and the asset is vital to the success of a brand new, high-profit product being introduced to the site. This product is enough to keep the site operational for many years to come. The installation of the asset is

A major asset is being installed, and the asset is vital to the success of a brand new, high-profit product being introduced to the site. This product is enough to keep the site operational for many years to come. The installation of the asset is

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.