Ramesh Gulati and George Williams discuss Certifications and the importance of obtaining them.

[Read more…]Your Reliability Engineering Professional Development Site

A listing in reverse chronological order of these article series:

by Ramesh Gulati Leave a Comment

Ramesh Gulati and George Williams discuss Certifications and the importance of obtaining them.

[Read more…]by André-Michel Ferrari Leave a Comment

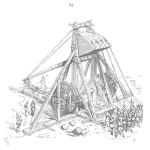

Maintenance Optimization is a Reliability Engineering process which helps organizations avoid unnecessary spend whilst minimizing the risk of a costly failure. Planned replacements or inspections detect or prevent failures for components or systems with increasing failure rates. This improves asset reliability and helps control maintenance spend. Increasing failure rates refer to having a Weibull distribution shape parameter Beta (β) greater than one. Specifically, the failure rates located in the right section of the bath tub curve as shown in Diagram 1 below. Admittedly, the life characteristics have to follow a Weibull distribution in this case.

by Mike Sondalini Leave a Comment

When engineers design a machinery part, they begin by defining the operating load range it will experience during its service life. This range will include the loads when the machine part is not working through to the maximum stress that it will operate under. Examples of high stress situations include operating overload events, or when starting up under a large load. How great the imposed stress reaches and how often those events occur changes a part’s reliability.

[Read more…]by Nancy Regan Leave a Comment

Reliability Centered Maintenance principles will be celebrating their golden anniversary soon. And you may be surprised where the process finds its roots!

[Read more…]by Nancy Regan Leave a Comment

There is a big difference between Preventive Maintenance Optimization (PMO) and Reliability Centered Maintenance (RCM). Daffodils are a perfect way to explain the difference.

[Read more…]by Mike Sondalini Leave a Comment

Maintenance Work Backlog Management: a Start in Managing Maintenance! A maintenance manager can commence a maintenance improvement programme by simply creating opportunities for individuals and groups to make high performance contributions. One way to do this is to manage the Maintenance Backlog.

[Read more…]by André-Michel Ferrari 2 Comments

In line with the RAM acronym sequence, we often start and go no further than the “R” in Reliability. In doing so, we forget about the “M”. The question often asked is: “what is the reliability of the system?” But rarely asked is: “what is the maintainability of the same system?” Myself, am guilty of this omission. Hence this article to remind myself and you the reader, of the importance of Maintainability in industry.

[Read more…]

Human error causes 80% of plant and equipment failures. It is the single factor, which if controlled, makes the most difference to achieving world class equipment reliability and operational success. With the introduction of low cost communication and visual devices it is now possible to assist maintenance workers proactively prevent human error. By using interactive audio-visual devices workers can be coached through a job error-free to get right-first-time quality every time.

by Nancy Regan Leave a Comment

No way. It helps if you have a love – or even a fondness – for equipment maintenance and reliability. But other than that, just put your thinking cap on and you’re good-to-go!

[Read more…]by Karl Burnett Leave a Comment

In 1861, Royal Navy regulations updated the Captain’s responsibilities. Centralized management control of the technical system continued to grow. Regulations now prevented Captains from modifying the ship. Many new standard report forms were required to be routed to superior offices in the bureaucracy.

Many rules from the 1717 and 1731 regulations were kept, for example: managing ship surveys, tracking repair costs, written communications with the dockyard about defects and their status, and periodic caulking.

[Read more…]by Mike Sondalini Leave a Comment

Using a comprehensive and inclusive definition, risk may be defined as the cost of “failure to add value” per unit time. Such failure includes performance deficiencies for employees, equipment, material and method. It includes the types of “failure to add value” comprising traditional waste such as overproduction, wait time, transportation, processing, inventory, motion and defects. It includes the cost of injury, litigation and damage to company reputation. It encompasses the total cost of failure and not just the cost of remediation. You must minimize risk to stay competitive. Risk is consuming the hidden wealth of your enterprise. It is disguised and concealed as the “cost of doing business.”

by Ramesh Gulati Leave a Comment

by André-Michel Ferrari 2 Comments

A proper CMMS (Computerized Maintenance Management System) setup can make a world of difference in an organization’s asset management journey. Conversely, a substandard setup can be a living hell for Reliability Engineers like myself and other analysts. I have personally wasted hundreds of hours of my work life sifting through a poor CMMS structure trying to find records. Ever wanted to make your Reliability Analysts more productive and engaged? If yes, then this article highlights 10 highly recommended set-up requirements.

[Read more…]by Mike Sondalini Leave a Comment

Let a Plant Wellness Way EAM System-of-Reliability halve your Annual Maintenance Costs

A Plant Wellness Way enterprise asset management system is a powerful solution for world class enterprise asset management (EAM) success. There are three scenarios when it is justifiable for a business to adopt PWW EAM as your company’s EAM methodology.

[Read more…] Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.