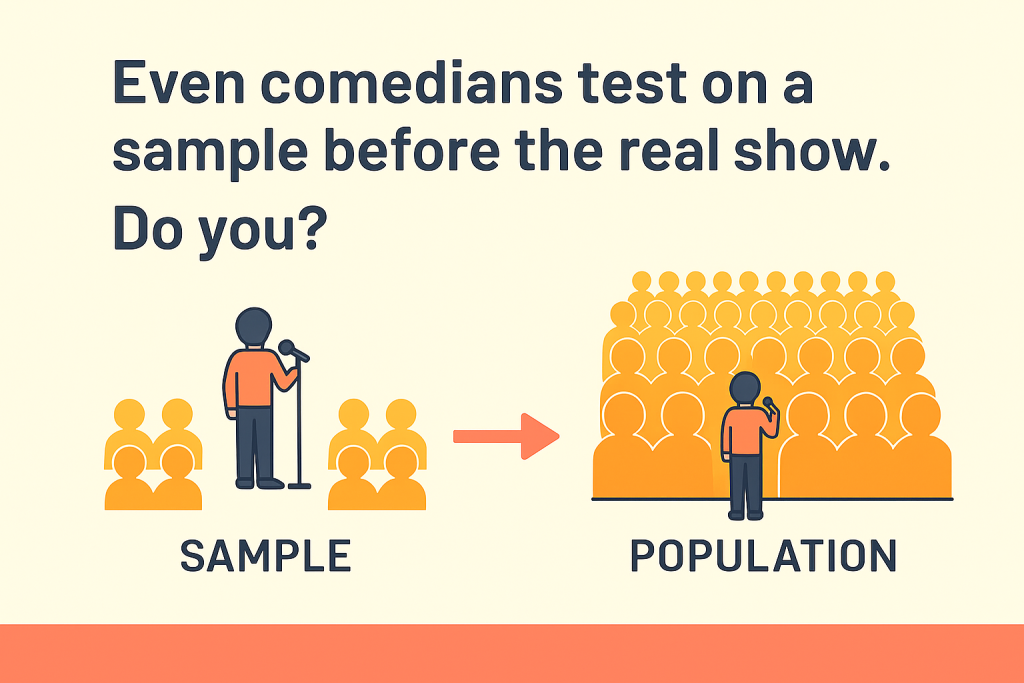

As industries increasingly rely on complex electromechanical systems, the importance of Return Parts Analysis (RPA) cannot be overstated. This crucial process involves forensic examination of failed components to determine root causes and prevent future issues. Let’s explore why RPA is essential, particularly for components like valves, sensors, pumps, and electrical boards.

Return Parts Analysis provides invaluable insights into component failures, offering benefits that extend far beyond simple troubleshooting:

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.