Transformations are useful techniques. Why and how would you use them? The selection process is important, as a well justified choice improves decision making and communication. [Read more…]

Your Reliability Engineering Professional Development Site

Find all articles across all article series listed in reverse chronological order.

by Perry Parendo Leave a Comment

Transformations are useful techniques. Why and how would you use them? The selection process is important, as a well justified choice improves decision making and communication. [Read more…]

by Bryan Christiansen Leave a Comment

Equipment maintenance is a requisite for companies that seek high-performance from their physical assets. If they can leverage a well-executed maintenance strategy, such organizations should gain the expected advantages that reliable assets will deliver such as reductions in operational costs and unplanned shutdowns.

by Nancy Regan Leave a Comment

I never would have thought that a “productivity tip” also held the key to starting (or continuing) your RCM program. Watch as I explain (from Vegas!) how spending only 10 minutes a day can help you achieve greatness with RCM and with your personal and professional life! [Read more…]

by George Williams Leave a Comment

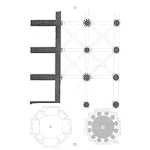

Example of classifications utilization in CMMS. Provides an overview of what classifications and attributes are and some of the places they can be utilized within the CMMS. [Read more…]

Reliability is a process. If the right process is followed, results can be great such as eliminating most of the warranty costs. The opposite is also true in the absence of the right process. There is a saying: “If we don’t know where we are going, that’s where we will go.” It is difficult enough to do the right things, but it is even more difficult to know

what the right things are!

Knowledge of the right things comes from practicing the use of lessons learned. One must utilize the accumulated knowledge for arriving at correct decisions. Theory is not enough. One must keep becoming better by practicing. Take the example of swimming. One cannot learn to swim from books alone; one must practice swimming. It is okay to fail as long as mistakes are the stepping stones to failure prevention. Thomas Edison was reminded that he failed 2000 times before the success of the light bulb. His answer, “I never failed. There were 2000 steps in this process.” We can use the following lessons learned. [Read more…]

by Perry Parendo Leave a Comment

Our training provides experience with practical application, including team building and economic considerations. This testimony captures those experiences. Would you benefit from this training approach? [Read more…]

by Adam Bahret Leave a Comment

My wife (Beth) and I both train and compete in Brazilian Jiu Jitsu. It’s a grappling sport like wrestling. In Jiu Jitsu your Gi (the karate looking uniform) is a big part of the sport. It’s a very heavy fabric with very specific features that are inspected before each match. Many moves involve the GI, especially the jacket. I have wrapped my sleeve around someones neck for a choke, You can grab the end of both of the opponents sleeves and dig your feed into their elbows to lock up their arms and throw them, you can use an opponent’s own lapel and wrap it around their neck for a submission or simply to roll them any way you wish.

by Nancy Regan Leave a Comment

Watch as I describe how maintenance can help us to achieve our equipment’s inherent reliability, but it can’t make a machine something that it isn’t. If we’re doing the right maintenance, and we still don’t have the reliability we want, we have two choices… [Read more…]

by George Williams Leave a Comment

Part 1 of our interview with Sunil Kamerkar of AssetAnalytix. In this session, we discuss what analytics is and challenges faced when looking to utilize data. [Read more…]

by Perry Parendo Leave a Comment

Early in engineering, it seemed the purpose was to create products that made life easier. But eventually, I started to wonder – does that make life better? This video discusses that contradiction. [Read more…]

by Greg Hutchins Leave a Comment

What is ‘the sum of all fears‘…apart from a Hollywood movie? During WW2 Winston Churchill knew the risk of failure and he postulated that, even when courageous people amalgamate, they will know fear:

“…take the most gallant sailor, the most intrepid airman or the most audacious soldier, put them at a table together – what do you get? The sum of [all] their fears”. War is a much more serious endeavour than any civilian project but fear is fear. If a project teeters into trouble the Project Team will fear failure. They must then deal with this reaction and have the courage to overcome trouble and avoid failure. [Read more…]

by George Williams Leave a Comment

Quick overview of CMMS meters and why you should use them. [Read more…]

by Nancy Regan Leave a Comment

When it comes to managing risk, there are three elements to consider and RCM can help you define all three. Watch as I manage risk and change consequences all at once! [Read more…]

by Adam Bahret Leave a Comment

It’s been a few years since I have had a Porsche 911 in the stable. It seemed like the right time since were down to only two  sports cars in addition to the daily drivers. I think five cars is the bare minimum these days. “It’s only a problem if you want to stop but can’t.” I don’t want to. There are some less free spirited individuals in the house who have expressed differing opinions.

sports cars in addition to the daily drivers. I think five cars is the bare minimum these days. “It’s only a problem if you want to stop but can’t.” I don’t want to. There are some less free spirited individuals in the house who have expressed differing opinions.

by Greg Hutchins Leave a Comment

Guest Post by Geary Sikich (first posted on CERM ® RISK INSIGHTS – reposted here with permission)

There seem to be a lot of sightings of “Black Swans” lately. Should we be concerned or are we wishfully thinking, caught up in media hype; or are we misinterpreting what a “Black Swan” event really is? The term “Black Swan” has become a popular buzzword for many; including, contingency planners, risk managers and consultants. However, are there really that many occurrences that qualify to meet the requirement of being termed a “Black Swan” or are we just caught up in the popularity of the moment? [Read more…]

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.