During the design phase, we make decisions that create the eventual reliability performance of a product.

It is the decisions we make that matter.

Also during the design phase, we explore numerous questions. [Read more…]

Your Reliability Engineering Professional Development Site

Find all articles across all article series listed in reverse chronological order.

by Fred Schenkelberg Leave a Comment

During the design phase, we make decisions that create the eventual reliability performance of a product.

It is the decisions we make that matter.

Also during the design phase, we explore numerous questions. [Read more…]

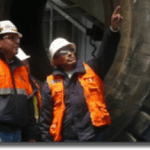

by James Reyes-Picknell Leave a Comment

Welcome to part nine of my 10-part series of blogs called “Uptime Insights”, where we explore a journey of excellence in maintenance. To stay on top, managers must implement strategies that keep operations performing at high levels. In these articles I will show you how to achieve excellence in maintenance – a critical business process in any capital intensive industry. [Read more…]

by Mike Sondalini Leave a Comment

Net positive suction head losses (or why you can suck through a straw).

Pumps cavitate and run dry when the pressure leading into them falls below the vapor pressure of what they are pumping. At vapor pressure, the liquid boils into a vapor and fills the pipe.

In order to know that the pressure to a pump is always above the vapor pressure, it is necessary to calculate that the pressure losses from pipe friction and suction lift will not cause the pressure to drop under the vapor pressure.

The presence of dissolved gas in the liquid complicates the problem. [Read more…]

by Greg Hutchins Leave a Comment

Guest Post by Keith Ridgeway (first posted on CERM ® RISK INSIGHTS – reposted here with permission)

Did you know on average around 30% of all organisations do not know what they own, where their assets are located or who is using them; and over 65% of information recorded on asset registers is incomplete, inaccurate or even missing. What’s more concerning is a number of these assets may not be statutory compliant e.g passenger/good/DDA lifts, fire, gas, pressure asset etc. [Read more…]

by Fred Schenkelberg 5 Comments

We’ve collected data and it’s time for the analysis.

As you may recall, in the last article on Planning a Taguchi L4 Array Experiment, we drafted a set of four prototypes. The specific arrangement of factors and levels will now allow us to analyze each factor separately.

The intent is to find the optimal level or setting for each factor, plus which is the most important factor. [Read more…]

by Fred Schenkelberg Leave a Comment

In deciding what industry you want to work as a reliability engineer, it is always good to have an understanding of what functional responsibilities you are expected to execute as a part of the job function.

You should always carefully review the job description then compare your knowledge acquired through training and on-the-job experience and ask yourself if you are capable of performing functions required without additional training.

Furthermore, we need to consider our technical limitations and at the same time be aware that the job description provided may not exclusive represents all the tasks you are expected to perform. [Read more…]

by James Reyes-Picknell 2 Comments

Welcome to part eight of my 10-part series of blogs called “Uptime Insights”, where we explore a journey of excellence in maintenance. To stay on top, managers must implement strategies that keep operations performing at high levels. In these articles I will show you how to achieve excellence in maintenance – a critical business process in any capital intensive industry. [Read more…]

Pressure vessels must be regularly inspected and be maintained in a safe operating condition.

New Australian laws stipulate that all pressure vessels must have a Hazard Level rating (‘A’ highest to ‘E’ lowest) which reflects the vessel’s safety risk (see AS3920.1).

The higher the risk the more stringent the requirements for operating and inspecting the vessel.

Keywords: receiver, non-destructive testing, internal inspection. [Read more…]

We hear a lot about things that are being called “Black Swans” today thanks to Nassim Taleb and his extremely successful book, “The Black Swan: The Impact of the Highly Improbable,” now in its second edition. I have written several articles centering on the “Black Swan” phenomenon; defending, clarifying and analyzing the nature of “Black Swan” events. And, I am finding that wildly improbable events are becoming perfectly routine events. [Read more…]

by Fred Schenkelberg Leave a Comment

One of the simplest ways to learn design of experiments, DOE, is to just give it a try.

The Taguchi DOE approach uses orthogonal arrays. This subset of the possible approaches to DOE simplifies the process to create and analyze experiments.

Let’s plan a simple experiment using the Taguchi DOE approach. [Read more…]

by James Reyes-Picknell Leave a Comment

Welcome to part seven of my 10-part series of blogs called “Uptime Insights”, where we explore a journey of excellence in maintenance. To stay on top, managers must implement strategies that keep operations performing at high levels. In these articles I will show you how to achieve excellence in maintenance – a critical business process in any capital intensive industry. [Read more…]

Get mechanical seals working properly.

Mechanical seals are used to keep the bulk contents of rotating equipment such as pumps and compressors from escaping. They do this by sealing the shaft that protrudes from the casing.

They require quality installation and operating conditions for a long life. [Read more…]

Guest Post by Roxann Dawson (first posted on CERM ® RISK INSIGHTS – reposted here with permission)

In order to improve business performance, manufacturing companies need to reduce the levels of non-conformance and attendant failure costs stemming from poor product design and development. Failure costs generally make up the largest cost category in a manufacturing business and include those attributable to rework, scrap, warranty claims, product recall and product liability claims. This represents lost profit to a business and as a result, it is the area in which the greatest improvement in competitiveness can be made. [Read more…]

by James Reyes-Picknell Leave a Comment

Welcome to part six of my 10-part series of blogs called “Uptime Insights”, where we explore a journey of excellence in maintenance. To stay on top, managers must implement strategies that keep operations performing at high levels. In these articles I will show you how to achieve excellence in maintenance – a critical business process in any capital intensive industry. [Read more…]

by Greg Hutchins Leave a Comment

Guest Post by Greg Hutchins (first posted on CERM ® RISK INSIGHTS – reposted here with permission)

More ISO management systems are incorporating RBT and risk, so the standard is becoming a ‘must know’ standard. ISO 31000 risk management principles, risk management framework, and risk management process are the preferred tools to use with ISO management systems because ISO 31000: [Read more…]

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.