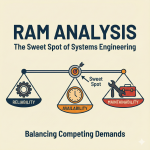

In an increasingly complex and interconnected world, ensuring that systems—from machinery to software, from power networks to consumer products—perform reliably across their intended lifetimes, is essential not only for safety and quality but also for economic viability. This intersection between ensuring dependable performance and managing costs is broadly studied under what is known as Reliability Engineering and Economics. Or Relia-nomics.

[Read more…]

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.