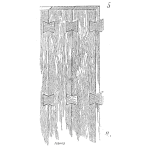

In this original post, A Mechanic’s Story: Basic Component Fatigue, we took a detailed journey through the physical side of a shaft failure RCA. We stopped at the physical side of that failure, parallel misalignment. However, stopping at the component level of failure does not constitute a credible and thorough RCA. Actually stopping at this level is more along the lines of a Shallow Cause Analysis (SCA). So let’s explore what makes the difference between a Shallow Cause Analysis and a Root Cause Analysis (RCA).

In the previous post we stopped at parallel misalignment. We will continue drilling from that point down. We ask ‘How could we have had parallel misalignment?’ Our team of subject matter experts (SME) hypothesizes 1) it was either misalignment at installation or 2) it became misaligned during operations.

[Read more…]

When you hear the work assessment or audit, does it send shivers down your spine? Do you envision a week or two of some “expert” digging through your data, processes, and performance, looking to get you in trouble for something you did or didn’t do?

When you hear the work assessment or audit, does it send shivers down your spine? Do you envision a week or two of some “expert” digging through your data, processes, and performance, looking to get you in trouble for something you did or didn’t do?

An assessment was performed and many opportunities identified, but it has been three months, and nothing has changed. Does this sound familiar? As discussed in a previous post, the goal of an assessment is to identify gap to best practices and provide the basis to develop a plan to move forward. However, many times an assessment is performed, the results put into a binder and put on the shelf (does this sound like your RCM initiative?).

An assessment was performed and many opportunities identified, but it has been three months, and nothing has changed. Does this sound familiar? As discussed in a previous post, the goal of an assessment is to identify gap to best practices and provide the basis to develop a plan to move forward. However, many times an assessment is performed, the results put into a binder and put on the shelf (does this sound like your RCM initiative?).

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.