Reliability Centered Maintenance (RCM) is extremely useful for organizations considering certification in Asset Management or looking at improving their asset care practices.

Exploring RCM as a tool, getting training for instance, is something that any organization interested in Capital Asset Management™, Asset Management or compliance to ISO 55001, really should do. Here’s why…

It is, without doubt, the best method for determining failure management policies for physical assets in their present operating context. It first proved itself in the airline industry (where it was developed) and has found application in many industries. At first blush, one might think RCM is about maintenance, but that’s not the case. How can it help in the broad realm of Capital Asset Management™?

Despite its name, RCM is not just about developing maintenance programs. It has a number of other outputs as well that can impact on engineering design, training, procedures, processes, etc. What RCM achieves with all those outputs is excellent risk management – something that the Asset Management standards are looking for and emphasizing. The standards are looking to achieve a balanced of asset performance with cost, risk and opportunity. RCM achieves that very well for any given asset in any given operating context.

At the design stage, RCM is useful in creating a whole follow-on supporting infrastructure for that asset. It is also very useful in spotting design flaws that might be improved to attain the desired performance. In doing so, RCM is a great way to minimize future operational risks to cost, performance, safety and the environment. It also does it at the best possible time – during design and before you are committed to hardware configurations.

Later in the “life” of the asset, once it has begun operations, RCM still has a role. It still produces an array of failure management policies relevant to the asset in its operating context. If it wasn’t used at the design stage, application of RCM may still reveal the same sort of design flaws, but sadly at this point, it can be more expensive to implement changes. There is more onus on handling those with procedural changes, training, maintenance or operational tasks. The only other drawback to doing RCM at this later stage of the life-cycle of the asset is that you may have already experience the negative consequences of some failures before you do the analysis and refine your programs. Regardless, going forward, it does achieve the same sort of risk management outcomes with respect to costs, safety, environment and performance.

In this article I will relate RCM to specific aspects of Capital Asset Management™ as defined in the standard, ISO 55001.

The standard is divided into 7 main subject areas:

- Organizational Context,

- Leadership,

- Planning,

- Support,

- Operation,

- Performance Evaluation, and

- Improvement

Each of those has a number of requirements that must be met for compliance to the standard. Each is expressed with a “shall” statement and there are some 72 of those that organizations need to consider. We won’t cover each of those, but we will cover each of the 7 main subjects and how it relates to RCM and vice versa. Keep reading to see how these two fit.

Organizational Context

Like Capital Asset Management™, RCM is context sensitive. Each asset’s failure management policies are defined relative to the context in which the asset is used. The first step of RCM requires that we define an “operating context” describing the asset under analysis and their context – how used, what they do, how they impact the business to meet stakeholder requirements and expectations, etc. An organization’s “Strategic Asset Management Plan” (SAMP) must also consider and define this same context at a business level. The scope to which the standard applies is defined in the SAMP. Given RCM’s rigor, it is typically applied only to critical assets – those that impact the business context most significantly. Most organizations will likely use formal Asset Management approaches for those same critical assets.

You can see that we are considering the same assets, the same operating and business contexts. Capital Asset Management™ defines what must be done to manage them, RCM defines how specifically to do that case by case. Furthermore, RCM provides excellent documentation of both the method applied, the analyses used to make decisions and the decisions. That is an excellent audit trail that any ISO auditor could use easily.

Leadership

This aspect of Capital Asset Management™ is more about the organization and people than the assets themselves. It speaks to leadership and commitment, policy and organizational roles, and to responsibilities and authorities. The organizations “asset management system” (i.e.: what it does) must tie into the organization’s business processes and the necessary resources to execute on the SAMP must be available. It is necessary to demonstrate that you are achieving desired outcomes. One of the most important requirements is to alignment of risk management for assets with the organizations risk management regime.

RCM is an analytical method that produces decisions. It is exactly the right tool to show how work that is executed in the field (e.g.: maintenance tasks, operator rounds) are defined in a methodical way that considers risks to the business. Once operating context is defined, RCM requires definition of functions and performance standards – these are the specific outcomes required from specific assets. The potential to fail at meeting those is what RCM targets. RCM outputs, once applied and complied with in the field, are a very visible and auditable way to demonstrate achieving specific outcomes from assets.

In the area of risk, there are a variety of tools that companies use but very few actually quantify risks across the broad spectrum of business context specific risks. RCM deals very specifically with risks to safety, environment, operating costs, production output / throughput and others if defined in the operating context and statements of asset functions. Not only does it deal with these risks, it does so quantitatively as part of the decision making on failure management policies.

Planning

In Capital Asset Management™ plans are developed and implemented to detail how the organization will deal specifically with risks, opportunities and meeting its objectives. RCM is one method that is an exact fit with the requirement to manage risks, define what specific activities will be executed to sustain asset performance as well as those needed to address shortfalls in performance. It is used to define, maintenance, operational, engineering, training requirements needed to sustain performance while managing risks. Leveraging the outcomes of RCM take this even further in defining the resources needed to carry out those activities and the time frames for doing so (frequencies for execution of tasks).

To fully appreciate the power of RCM as a tool to aid in planning see Part 2 Setup.

Support

Providing support to the asset management activities you define in your SAMP is a key requirement – without support those activities will fall short and fail to achieve their specific objectives. Those supporting activities involve many groups within an organization. Execution of the tasks pertaining specifically to the physical assets normally falls to maintenance and operational staff with design changes that might be needed falling to engineering. But those groups, particularly maintenance, require support – training, spare parts, purchasing services, contractors, shop facilities, tooling, etc. While it may seem evident, the maintainers, operators and engineers must also be competent. They must be chosen (recruited, hired and inducted) as well as trained to meet the specific needs of the organization. They will all rely on documentation – procedures, processes, work flows, etc. that they use in carrying out their responsibilities within the asset management system.

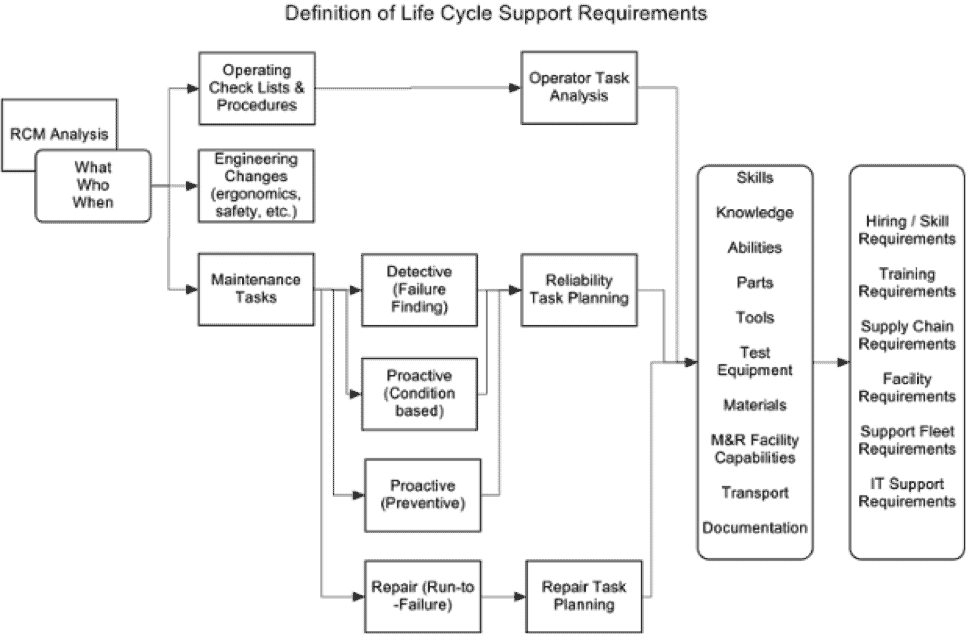

RCM is a tool for starting that whole process of defining support requirements. You can see from the following diagram just how RCM is used to do this:

The outcomes of following this process flow are a comprehensive definition of the support that must be provided to meet ISO 55001 compliance requirements.

Operation

In ISO 55001, this is the element where all the plans are executed. How you go about doing all this is beyond the scope of RCM, but it does outline what must be executed as described above.

RCM defines who does each of its outcomes. How they do it, requires definition of a detailed execution process. Each failure management policy defined using RCM is executed by someone – a maintainer (usually specifying the skills required), an operator, an engineer, training personnel, etc. Execution by those groups must be part of a defined process if those activities are to be done consistently and on an ongoing basis. Process are needed for: work execution by maintenance, ensuring operator rounds and tasks are included in shift operating guidelines, tasks sheets, etc., management of change to handle engineering recommendations and management of change for documentation and training changes.

While RCM doesn’t produce those processes, it is very useful in pointing out where they are needed and specifically what they are needed for.

Performance Evaluation

ISO 55001, like most ISO standards, follows a format complying with the well-known Deming Cycle: Plan, Do, Check, Act. We plan what we will do, we do it, we check that it was done properly and that it got desired results, and then we act to correct any deficiencies identified.

RCM is perhaps most helpful at the “plan” step, it defines what we must “do” and provides us with specific performance targets that we can check against. Once we’ve checked our outcomes, the action on correcting deficiencies can often be done by revisiting completed RCM analyses. We would, after all, already have a well-documented audit trail showing how we arrived at the various decisions for failure management activities. It only stands to reason that the same method be used to correct any deficiencies as they become evident in operation. For instance, an incorrect assumption about failure rates (perhaps due to a lack of failure data) can be corrected when the task frequencies that were defined don’t work as expected.

Performance evaluation requires that you begin with some defined targets against which to measure. RCM starts with definition of functional performance requirements (targets) which are quantified. Its analysis defines what to do to sustain performance at those levels. Review of actual performance against those targets is easily done and RCM even provides enough information so we can see where we may have erred in doing the analysis.

Even the RCM process itself has an inherent capability to identify where the analysis is going off-track when it does. Errors made early in the RCM analysis itself often become evident later in the analysis and long before decisions are acted upon in the field. The nature of the RCM process is that later steps in the process cannot be executed properly if the earlier steps contain errors.

The asset management system also needs to be audited. Auditing entails verification that you’ve defined what you are going to do, that you did it, that you monitor the outcomes and make corrections if and as needed. That all requires an “audit trail” of documentation and record keeping on activities executed. RCM provides the audit trail for how you made decisions on specific actions. Execution of those actions is tracked in work completion in your maintenance and other management systems that keep track of activity “transactions”. Monitoring of results for compliance and quality improvement involves both – RCM’s targets together with the field performance monitoring in other management systems. Corrective action to show that you are correcting for deviations from expected performance entails (among other things) reviews of earlier RCM analyses.

Improvement

Making improvements requires the ability to act on any non-conformances to process and / or expected performance. We’ve covered how you spot those above. Executing on corrections (improvements) may, in some cases mean that earlier decisions are questioned. RCM’s excellent documentation trail makes this easy to do. Any trained reviewer can go through an analysis, seeing not only the decisions made but the reasons for those decisions. Each step of the way through the process is fully documented and some of those steps are supported with in-depth economic or risk analyses that also form part of the audit trail. If there were errors highlighted by performance shortfalls, they are easily spotted by a trained reviewer.

Correcting errors, changes to decisions and implementing them entails following the same analysis and follow-up action that RCM defines so well.

Conclusion

While RCM may not have been developed with modern Capital Asset Management™ standards in mind, it was developed to support the same objectives: safe, environmental sound and cost effective functional performance of physical assets in the field to ensure those assets continue to do what their organizations need them to do in their operating contexts. It does so by defining what activities must be performed to achieve that whether they are maintenance, operator, engineering or other tasks. Long before Capital Asset Management™ was so formally defined in standards, RCM was aiming for the same results, albeit leaving much of the organizational and other aspects of “how to” achieve them, entirely in the hands of the organization. The standards today provide more guidance on those, but in-so-far as the assets themselves are concerned, RCM remains the best tool to use

To learn more visit Conscious Asset where you will find training, workshops, books, and resources.

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.

Leave a Reply