Experiences with magnetic (magdrive) pumps. Magnetic drive pumps come in three varieties – canned motor pumps, all metal pumps and plastic lined metal pumps. They are sealless and cannot leak into the environment. Long, repair- free service life depends on recognising the limitations of these pumps. This article covers issues with using direct mounted, lined magdrive pumps experienced ‘in the field’.

Keyword: separation liners, chemical compatibility, sediment, particulate.

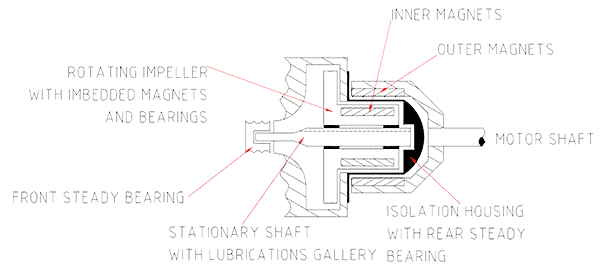

The smaller magdrive pumps sizes come with motors direct mounted to the pump and there are no shaft alignment problems. The internal bearings and shaft in the plastic lined pumps are usually corrosion-free hard silicon carbide. The process liquid lubricates the bearing surfaces. Canned motor pumps have dual containment.

They operate by using magnetic attraction and repulsion to turn the impeller. Within the pump is a set of high strength permanent magnets imbedded around the outside of a hub projecting from the back of the impeller. A thin liner or shroud with a small (2 – 4 mm) clearance to the hub seals the pump internals. At a similar distance on the outside of the liner is another set of magnets connected to the motor. As the motor turns the outside magnets drive the inside magnets.

Here are some problems that can arise with magdrive pumps.

- They cannot be run dry for more than a few seconds. When the bearings loose lubrication heat is quickly generated and conducted through the bearings. Plastic impellers can distort. Install no flow detection, like a flow switch or under-current detection, to protect the pump.

- A high amount of heat can be generated by the coupling action of the magnets. This is worst in the canned motor and metallic pumps. The heat warms the liquid in the pump and is passed into the process. In a refrigeration system the excess heat may exceed the design loads for the system.

- The pumps do not tolerate particulate and sediment in the pumped fluid. Because the process fluid lubricates the bearings, entrained sediment can block galleys and ports supplying lubrication. Only use them on clean fluids.

- Sediment will also work its way into the thin cavity between the outside of the impeller hub and the inside of the separation liner. The sediment is dragged around by the impeller hub and scours the liner. If allowed to continue the sediment gouges through the separation shroud and the pump leaks.

- Sediment settling on the bottom of tanks may come lose and be drawn through the pump. Set pump suction nozzles well off the tank floor.

- The heat generated by the action of the magnets may be high enough to bake constituents of the process liquid onto the impeller magnet hub and a build-up develops.

- Processes involving liquids that crystallise at room temperatures, or higher, require the pump to be trace heated to prevent crystals forming in internal cavities.

- Internal plastic liners of magdrive pumps are susceptible to damage if hard foreign objects are drawn through the pump. Install a suction strainer if the process can contain large foreign materials like wood and rock. Large solids can also block impeller passages.

- Separation liners made of non-conducting materials such as fiberglass and plastic composites cannot handle high pressure. If the pump experiences hydrostatic pressure from thermal expansion of liquid trapped between valves, or pressure hammers from fast closing valves, it is likely the separation liner will crack or rupture. Relieve thermal pressure build-up if closed valves can isolate the pump.

- Ferrous particles, such as rust or steel filings, will be attracted to the magnets. It is a particular problem when bulk solids containing traces of ferrous metal are dissolved in a tank or where tank bottoms are being cleaned out. In-line magnets on the pump suction can help reduce the problem, or the tank contents can be let to settle and then the clear liquid above pumped out. The contaminated ullage is handled separately by a different style of pump or method.

- Keep fingers away from the back of the impeller when it is reinstalled. The magnetic attraction between the inner and outer magnets cannot be restrained by hand and people have been hospitalised with crushed fingers.

- Under high unexpected flows and pressures the pump is required to deliver more power through the impeller. If the conditions are beyond the capacity of the pump, the magnets de-couple and the drive is lost. To reengage the magnets the pump needs to be stopped and restarted. When selecting a magdrive pump chose one that will handle likely peak conditions.

- In some situations the chemical being pumped has diffused through the plastic lining and attacked the underlying metal. This occurred on a magdrive pump pumping 26% HCl at 80o C. Through a manufacturing error the plastic lining over the impeller magnets was not up to standard and the HCl diffused through to the magnets where is corroded them and caused the inner magnet hub to bulge and rub against the separation shroud. Eventually the impeller jammed and would not turn.

- If you don’t need the liner for chemical protection then you can get a cheaper all-metal pump.

- These pumps can be wired-up incorrectly and run backwards. They will seem as if they are pumping but the flows and pressures will be much less then if they were going the right way.

Mike Sondalini – Maintenance Engineer

We (Accendo Reliability) published this article with the kind permission of Feed Forward Publishing, a subsidiary of BIN95.com

Web: trade-school.education

E-mail: info@trade-school.education

Very good information. Thanks sir, I need some more information magnetic coupling pump what are the applications are used and this main advantage of magnetic coupling pump. We are using magnetic coupling pump for HTM oil and some HTM oil pump with out Magnetic coupling pump also using.comparesion magnetic coupling pump failure is high.

Thanks for the comment. A good place to find information and benefit of magnetic coupling pumps is with a vendor or manufacturer of such devices. They can also take the time to understand your application. cheers, Fred

thank for useful information

any concern in reverse flow ?