Many equipment breakdowns and stoppages occur because of improper clearance between holes and shafts.

The shaft is too tight in the hole; the center of the hole is not at the center of the shaft making it off-center; one part is loose on another and slips out of place or does not seal as it should.

Clearance

Equipment is designed so that parts have either a gap between them so they can move separately to each other or they are firmly in contact and do not move relative to each other.

The gap or lack of it between the hole and shaft is called the clearance. Clearance is determined by the size difference between the parts.

Fits and tolerances are used to specify the size range of parts.

Fit

The types of fits have been given names.

They range from an interference fit, where the parts are purposely made to be forced together. This fit can be further described as heavy through to light interference.

Whereas a clearance fit is for parts made to have a space between them.

This fit can be further described as tight through to loose.

Between these two fits is the transition fit where interference may or may not occur.

The amount of interference or clearance is achieved by specifying the tolerance range for the parts possible sizes.

Tolerance

Because of gradual cutting tool wear and minute changes in the machine tool internals due to temperature changes and wear/movement of internal parts, machined items can not all be made perfectly to the same dimension.

It is permitted to make the part to within a range of sizes.

That range is called the tolerance on the dimension.

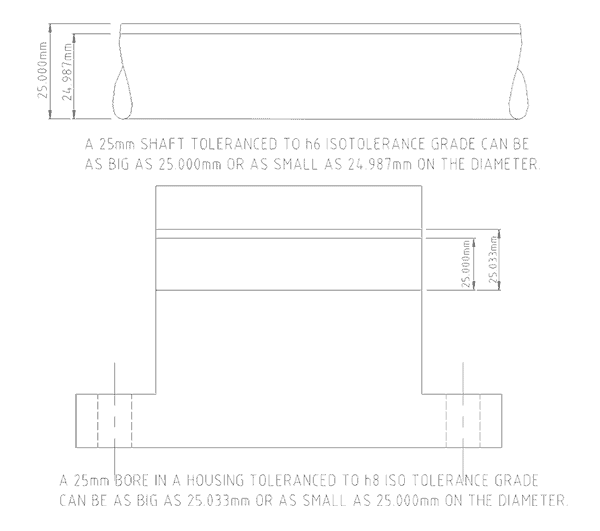

Figure 1. A dimensioned and toleranced shaft and hole.

Figure 1 shows a dimensioned shaft and a dimensioned hole in a block with tolerances to provide a transition fit when assembled.

At the largest sized shaft and the smallest sized hole, they would contact.

This tolerance is too tight for a shaft that had to move through the hole but might be suitable for the outer race of a bearing fitted in a bearing housing of a rotating shaft.

In such a case the bearing race must not move on the shaft (spin) as it will wear the shaft, so an interference fit might be suitable.

If the load on the bearing was large, or there was a lot of vibration or the shaft was spinning very fast it would be better to make it a light interference fit.

If the shaft were large and rotating at low speed and repairs had to be done by the tradesman while in-the-field without access to bearing removal and installation equipment, it might be better if it was a tight clearance fit.

Selection of tolerances for a part is made after considering –

- the speed at which the part moves

- the applied loads and forces it must withstand

- the amount of vibration permitted

- whether grease or oil lubrication is used ease of assembly

- changes in size due to thermal expansion.

Engineering drawings follow a recognized standard for displaying the dimensions and tolerances required for a machined part.

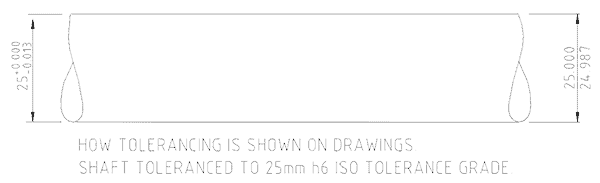

Figure 2 shows two acceptable ways to dimension and tolerance a part.

Figure 2. Methods for tolerancing parts

It is critical to know the fit, tolerance, and clearance required for replacement parts.

Often damaged parts are measured up in order to manufacture a replacement.

If the old part is worn and no allowance is made for wear, the clearances will be in error and the machine may not operate properly or for long.

Fitting tolerance parts

When tolerances are too loose parts rattle about causing vibration and wear.

An oversized bore on a shaft coupling allows it to flop about on the shaft. At high speed, the coupling is thrown about causing noise, vibration and shaft distortion. Bearing failure occurs well before time.

Always machine parts to the proper size and tolerance for the application.

Drive couplings must be bored centrally and axially to prevent out-of-balance.

Bored couplings directly mounted on the shaft should have a light interference fit and be heated on assembly to slide onto the shaft and key.

Machine parts heat-up when operated and they expand and change size.

If there is insufficient clearance when the parts have expanded they may contact, or loose contact or prevent sufficient lubrication thickness to develop.

When parts make contact heat is generated and material is scraped off into the lubrication system.

Eventually, contamination and damage become severe and the machine fails.

Thermal growth of machine parts can also cause alignment changes.

There have been occasions where a machine aligned when cold, goes out of alignment when at running temperature.

Various parts have grown in length with the warmth of operation and contacted neighboring parts.

The forces generated cause deformation and distortion.

Always measure & check the research

To be certain sufficient clearance is available between parts for radial and axial thermal growth the dimensions of the parts must be measured and the clearance checked.

Corresponding dimensions of each part are measured with micrometers.

The measurements are then subtracted from each other and the difference is the clearance when the parts are cold.

In critical applications, it is necessary to determine the growth in size when the machine is at operating temperature.

The formula for thermal expansion is available from machinery handbooks. The growth in size is added to the ‘cold’ dimensions and the clearances again determined.

An example of a thermal expansion problem because of insufficient clearance for shaft axial elongation was a bearing failure on a high speed rotating 80-mm (3”) shaft.

The shaft ran on two bearings mounted in separate housings. The drive end bearing was the floating bearing and the other the fixed bearing.

This configuration, of one fixed and one floating bearing, is the correct way to allow for shaft expansion. The fixed bearing’s outer race was clamped in place inside the housing by the end covers and spacers.

However, the axial clearance between the floating bearing’s outer race and the housing’s rear cover had not been checked and was insufficient.

As the shaft grew in length with the heat of operation, the floating bearing was forced against the end cover causing tremendous heat and noise.

During assembly..

During machine assembly, the available gap between holes and shafts can be readily checked with micrometers. It is more difficult to check axial spacing.

A simple method to check axial clearance is to insert plasticine between the shoulder and the abutting face and mount the parts fully.

The plasticine is squeezed into the available space and the parts are again stripped down and the thickness of the plasticine checked with a micrometer.

Only use enough plasticine so the parts still pull-up properly together as if finally assembled.

Mike Sondalini – Maintenance Engineer

If you found this interesting, you may like the ebook Bulk Materials Handling Introduction.

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.

It has been a very interesting write-up and reading, thanks for your contributions to knowledge in engineering.

Thanks for the time and energy you invested to write this information

Thanks for the kind words. cheers, Fred