“Use Case 7” is a concept I am rolling out. Use Case 7 is the way a customer may use your product in a manner that is way beyond anything you expect.

Examples:

- Me using a power drill as a hammer. “I’m not walking all the way back in the house to get a hammer just to put a nail in!”

- My Dad when he used to load 300lbs of firewood into the back of his Nissan Sentra. Then make us kids lay on top of it since the seats had to be folded down. But I think that last part is more of a child services situation.

- That wire shirt coat hanger with the leather motorcycle jacket on it, and three pairs of wet ski glove clipped to it…and you hold onto it when you bend down to pick up your shoes.

- You when you were sixteen and had your parents car in a full drift in the mall parking lot on Saturday night (I’m projecting here), or when you owned that same car and didn’t change the oil…ever (sorry Dad)

Why is it called Use Case 7?

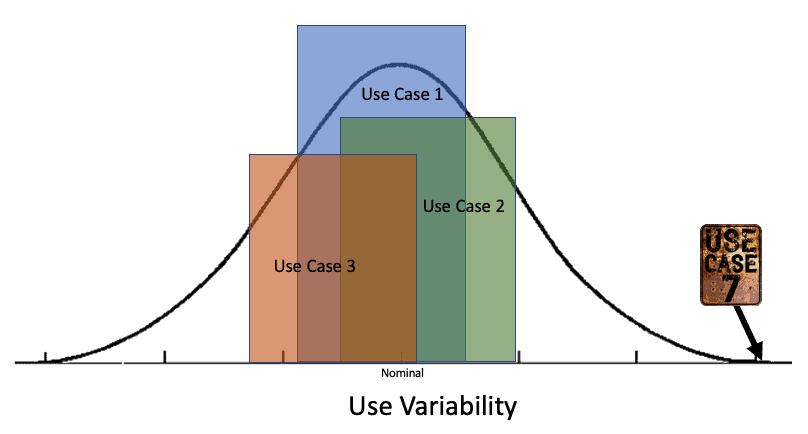

One of the first things I do with customers that want to better understand their products reliability is ensure we have clearly defined use cases. I can’t emphasise enough how critical this is. A reliability statement means absolutely NOTHING without a clearly defined use case attached to it. Advertising your plastic fork has a 99.999% reliability without indicating the this covers indoor one time use is a false statement. What if I use that fork when I go mountain camping in winter? How well does that fork work below freezing and used 5 days in a row?

In many cases a products use can be well characterised with three use cases. Sometimes it’s as simple as low, medium, high or “city driver”, “commuter “and “taxi driver. ” Sometimes with customers I will create as many as six. But how about one more? Come on… Please? It’s just one more and I it’s wafer thin. But what should we call it? Engineers aren’t marketing geniuses so…..”USE CASE 7″ Yes!!!

Use Case 7 covers the conditions that you do not cover in warranty, you write explicitly in the manual “not to do”, and you are suspicious may be the profile for some warranty returns that should not be paid.

But what if we studied Use Case 7 a bit? Could there be some helpful design input in there? Could it aid us in more precisely predicting failure in all use cases? I think it can, and I believe it should be explored whenever resource and time permits. I also believe many new products have been discovered because of accidental explorations into Use Case 7.

Use Case 7 fills a much needed gap between Stress Margin testing and HALT. What is Stress Margin Testing? Stress Margin testing aims to discover a products response to levels above nominal. These stresses are all based on the base intended use case. If we have a force load specification we explore what happens as we apply incrementally greater force. What happens to the product performance? How does it change and when? Stress Margin is a critical testing phase because reliability is fundamentally “The study and control of variability.” What’s the best way to mitigate uncontrollable variability in manufacturing, use, and environment? Make sure there is enough margin where you need it.

What is HALT? HALT testing uses the application of any destructive stress we can think of. If you have a sledge hammer available, use it.  Vibrate the product until if falls apart even though it doesn’t see vibration in use. Bring it down to -20C as fast as you can. Does it crack? The intent is to expose any failure mode that could possibly occur, and do this as quickly as possible. But finding failure modes quickly comes at a price. By being extreme and disconnected from actual use cases we can not correlate these failure modes to any specific use in the field.

Vibrate the product until if falls apart even though it doesn’t see vibration in use. Bring it down to -20C as fast as you can. Does it crack? The intent is to expose any failure mode that could possibly occur, and do this as quickly as possible. But finding failure modes quickly comes at a price. By being extreme and disconnected from actual use cases we can not correlate these failure modes to any specific use in the field.

But how does this help then? A failure mode found under extreme vibration may be representative of a failure mode under normal use that is driven by poor injection molding in manufacturing. By improving the design based on the failure found in vibration the robustness against manufacturing variability has been increased. We may never know which variability in which use case we have protected against. What we do know is that products that use HALT in the product development process have better reliability in the field. So it works even though it is a bit blind.

The gap Use Case 7 fills is finding response to stresses that, although unlikely, may occur and could be addressed with design improvement. We are able to add robustness through faster testing and correlate it to extreme field stresses. We may find ways to get that “bullet proof” label for your product by using Use Case 7. We may mitigate that failure mode that started to show up a year after release because the product is used in a manner we didn’t expect. We may improve the definitions of use cases 1 to 3 as we explore the unusual. Because sometimes the unusual is more common than we think. So start talking about Use Case 7 in design reviews. Just remember “It’s less fun for you when your customer does it first!”

So look for the new  logo on articles and in videos. I’ll be finding examples of Use Case 7 to dissect everywhere I go in coming months. (I’ll probably make some too)

logo on articles and in videos. I’ll be finding examples of Use Case 7 to dissect everywhere I go in coming months. (I’ll probably make some too)

-Adam

Leave a Reply