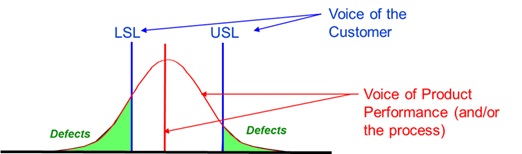

Recall the overall objective of product development is to develop the ‘right product’ and to develop the “product right”. In previous articles, we defined validation as a continuous process throughout product development to establish complete and correct requirements. Consider the following illustration:

Valid requirements represent the voice of the customer and acceptability of the product. Product performance represents the “voice of” the design and process. Product performance outside of spec limits result in defects and rework (it is not the right product to meet customer needs).

Let’s start with the easiest (and arguably, most likely) scenario: A product requirement isn’t known with good specificity. There is pressure to deliver the product to the customer and the customer expects a ‘fully qualified” product. Some validation doesn’t start until testing in the customers environment. [Read more…]

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.