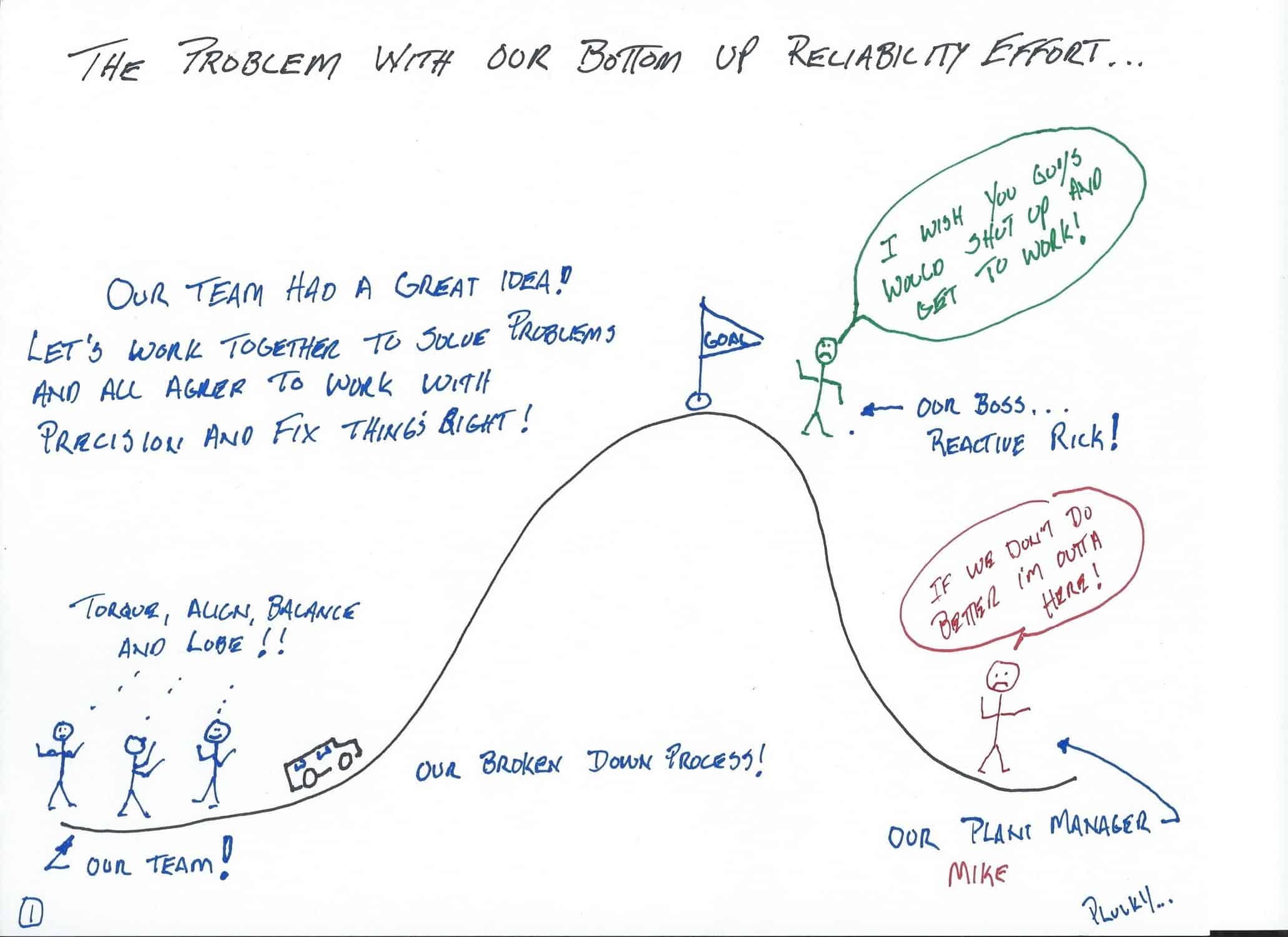

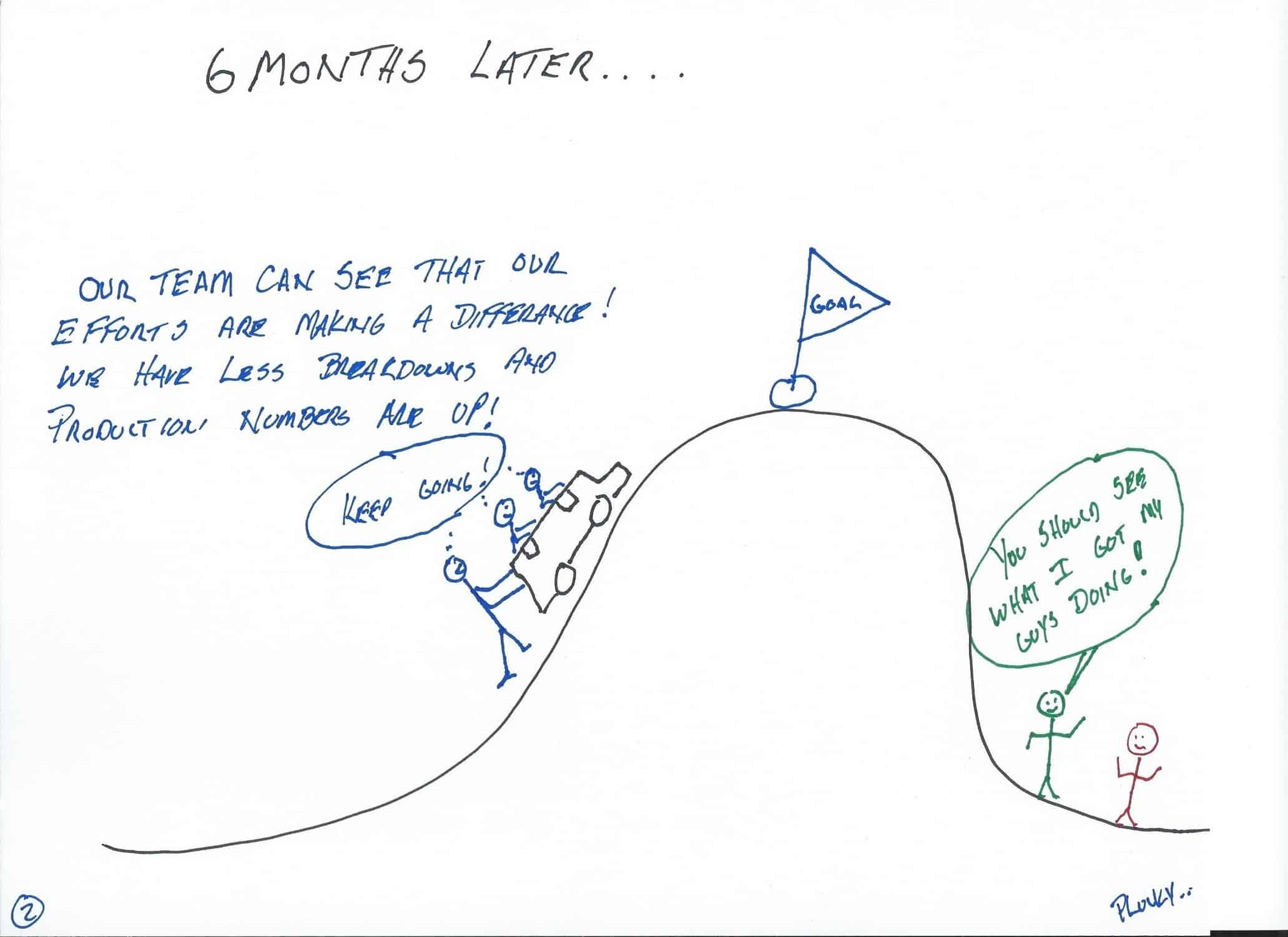

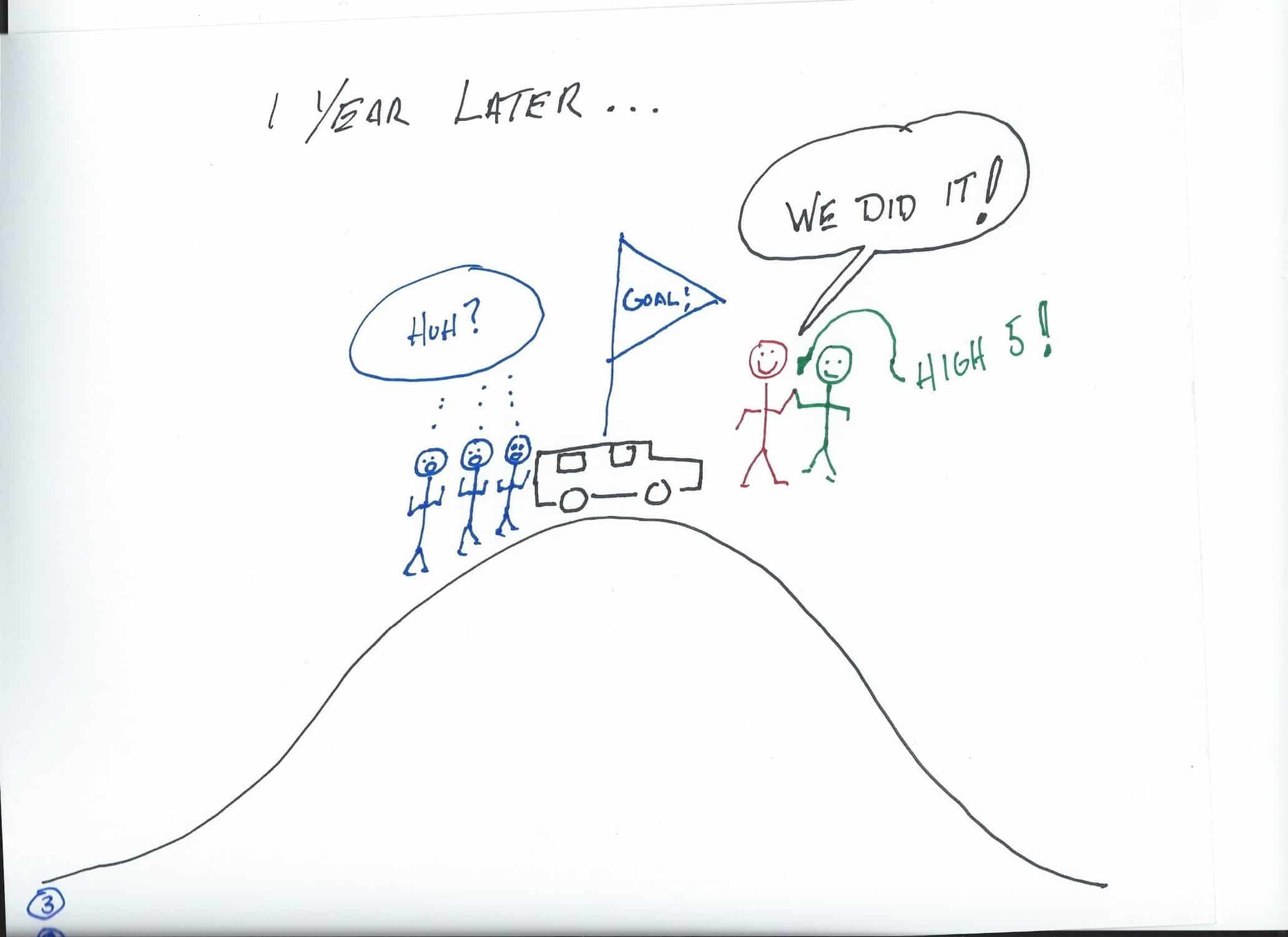

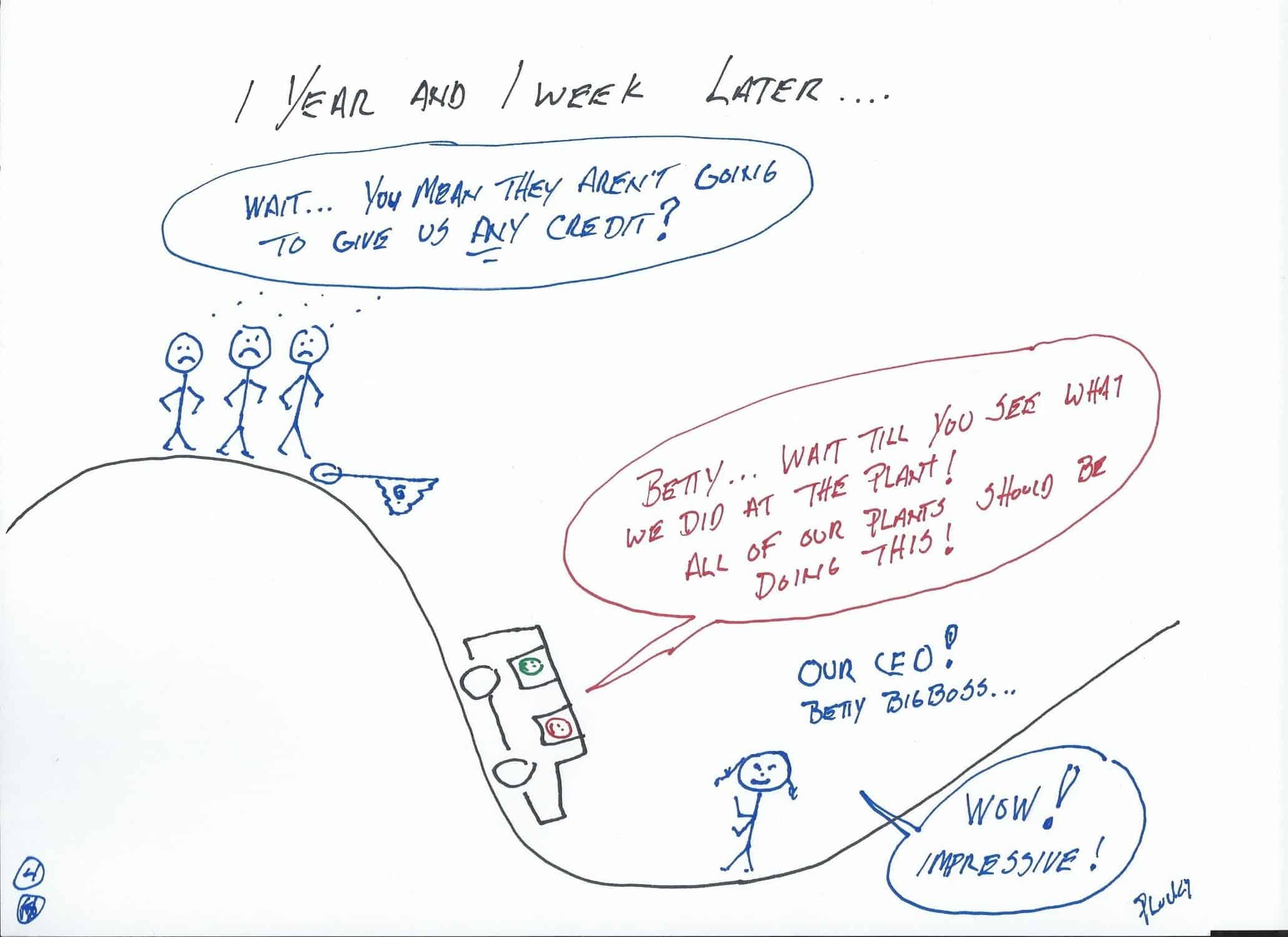

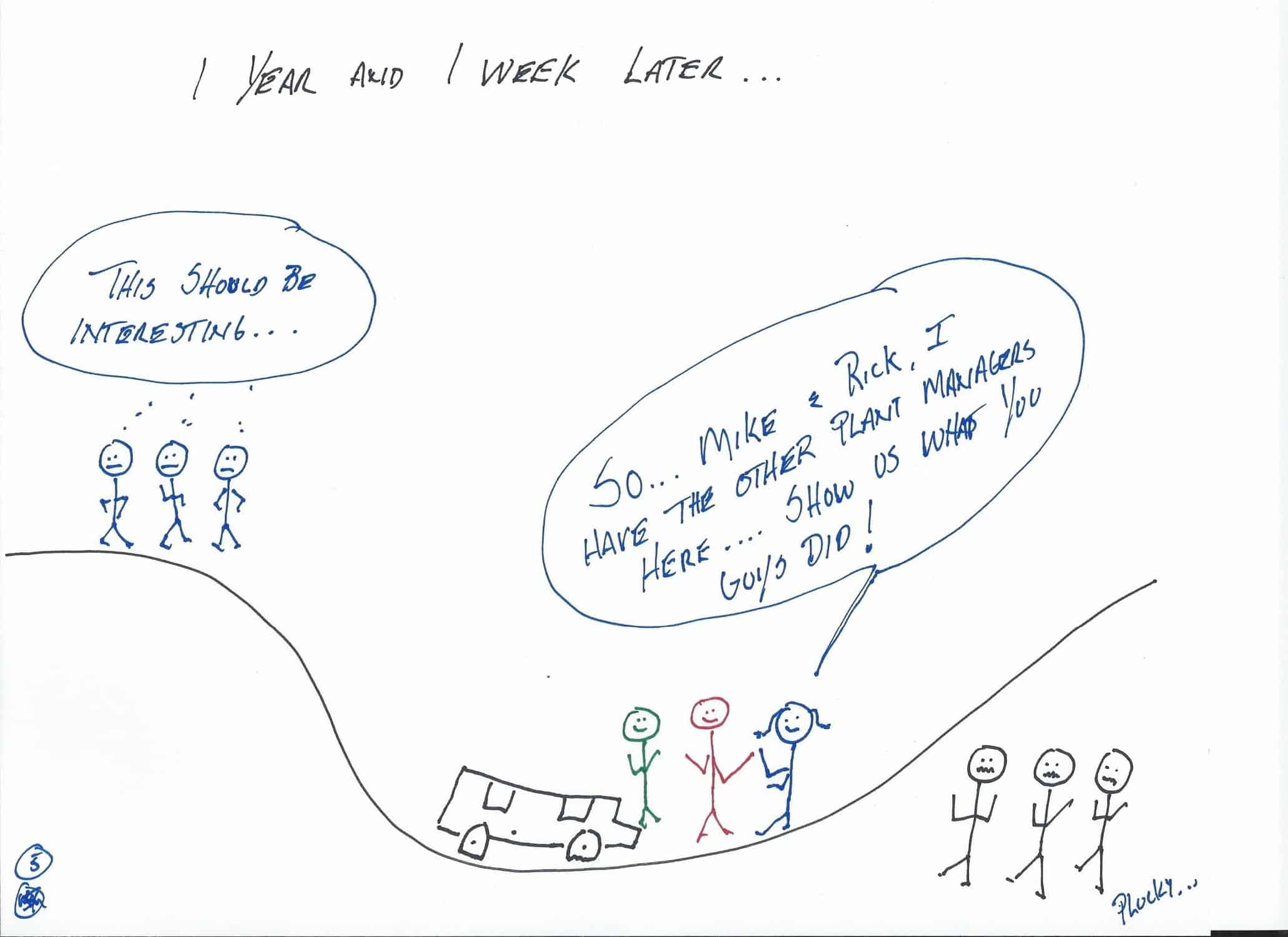

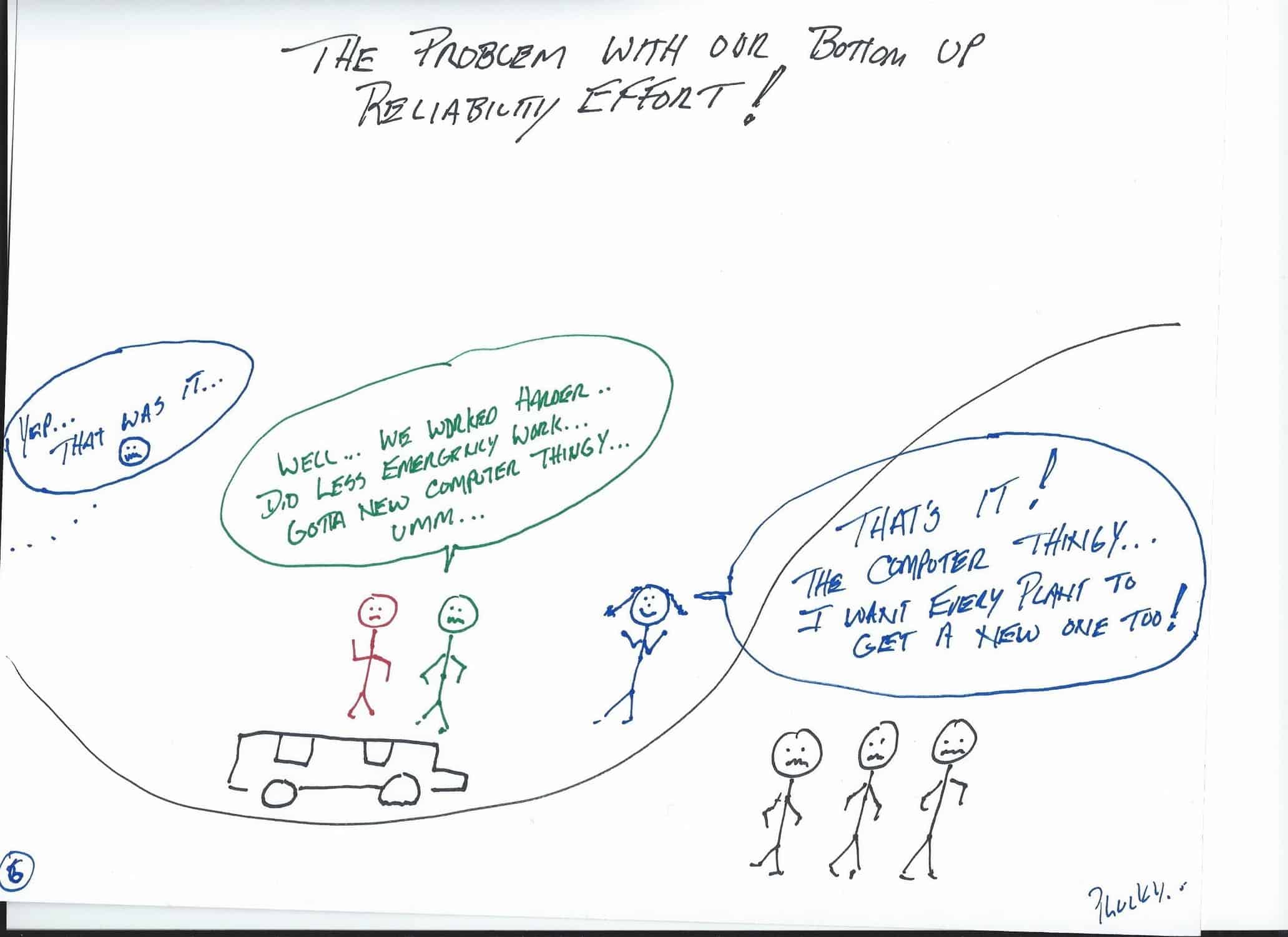

I’m using this week to get my office in order. This morning I found this series of drawings I did back around 1987. While I know my old friends from Building 317 will get a kick out of this, I also know that we weren’t the first and won’t be the last team of people who worked to make our plant a better place to work. I also know the last slide from this series is missing that showed the team alone saying “If you want to know how it happened, it pays to give credit where credit is due.”

In the following 30 years I have heard similar stories of bottom up efforts that started successful and then whimpered out when the success couldn’t be repeated in other areas. Teamwork is sometimes a fragile thing, it’s success teaters on trust at all levels.

I also know that the folks at LinkedIn suggest we avoid trying to use humor to make a point or send a message. I know we found this to be funny in 1987 and I laughed again when I saw it today….Even back then I was smart enough to change the names to protect…. well … Me! Enjoy and please, if you have a similar story please share or comment! And, if you like it please share!

Leave a Reply