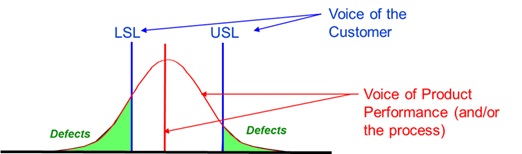

Recall the overall objective of product development is to develop the ‘right product’ and to develop the “product right”. In previous articles, we defined validation as a continuous process throughout product development to establish complete and correct requirements. Consider the following illustration:

Valid requirements represent the voice of the customer and acceptability of the product. Product performance represents the “voice of” the design and process. Product performance outside of spec limits result in defects and rework (it is not the right product to meet customer needs).

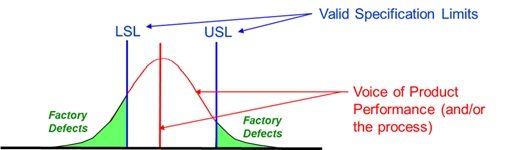

Let’s start with the easiest (and arguably, most likely) scenario: A product requirement isn’t known with good specificity. There is pressure to deliver the product to the customer and the customer expects a ‘fully qualified” product. Some validation doesn’t start until testing in the customers environment.

Parameters without clear specification limits result in rejects. Specification limits are clarified and escapes are prevented, however, defects and rework at the factory is now necessary. A redesign or process improvement is needed. Meanwhile, engineering has moved on to new products and may leave this activity up to operations or contract manufacturers to figure-out. This is illustrated as follows, with the diagram now showing valid specification limits:

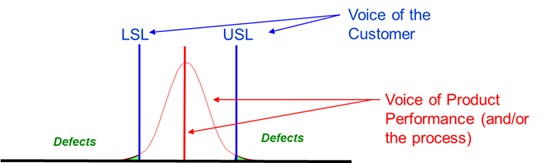

This messy scenario can be avoided with (1) valid requirements and specification limits before the design phase and (2) statistical design methodologies. Here, validation starts with product requirements not a post-development phase-gate. This also enables statistical design to consider optimizing tolerances to fall within the (valid) spec limits; designed according to design targets and process capability (mean and variability).

The diagram above illustrates an optimized design, verified according to valid requirements and an acceptably small percentage of defects. It is the right product and the product is built right (designed and manufactured) with few defects.

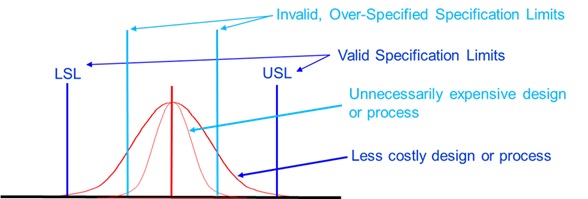

Consider another example involving specification limits that are unnecessarily tight:

With over-specified limits, we can still build the product “right” but with an unnecessarily expensive design or process. This is the product and process cost aspect of requirements validation…recall our goal is to maximize customer value and minimize cost.

Validation is a continuous process throughout product development to establish complete and correct requirements.

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.

Leave a Reply