Introduction

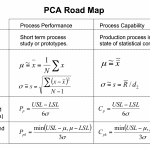

In my prior article, Process Capability I – Overview and Indices, the process capability concept was defined for prototype samples and serial production. The data is assumed to be normally distributed and Pp, Ppk, Cp, and Cpk indices were defined. Its application to one-sided and two-sided tolerances was discussed. This article provides methods to estimate the percent defective.

The Data

The engineering tolerance for a critical characteristic is 10±0.2. So the lower specification limit (LSL) is 9.8 and the upper specification limit (USL) is 10.2. A sample of 30 parts provided measurements of the critical characteristic. The sample mean ($-\bar{x}-$) was 9.951 and the sample standard deviation (s) was 0.1825.

Ask a question or send along a comment.

Please login to view and use the contact form.

Ask a question or send along a comment.

Please login to view and use the contact form.